Long Lasting High Frequency Welded Pipe Making Machine: Professional Steel Metal Former

https://www.youtube.com/watch?v=-q6CCJWhkrk

Introduction of Long Lasting High Frequency Welded Pipe Making Machine: Professional Steel Metal Former

High-speed welded pipe machines, with the in-depth integration of automated control technology, have simplified and optimized the operational process. Operators only need to set parameters and monitor the machine’s operating status to complete complex welding operations.

This not only reduces reliance on manual operation skills but also fundamentally improves the stability of the welding process.

Their core working principle lies in precisely controlling the current and voltage output by the welding power source to ensure a stable arc is formed at the welding joint, and then cooperating with high-speed rotating welding electrodes to quickly complete the welding operation on the joint surface.

This collaborative operation mode has achieved a qualitative leap in welding speed compared with traditional processes.

At the same time, the stable output of the arc and the uniform pressure of the electrodes ensure that the welded joint can meet the requirements of high-strength working conditions in terms of strength and adapt to various fluid transportation scenarios in terms of sealing performance.

Application of Welded Pipe

In the construction field, the application of high-speed welded pipe machines has become the key to the efficient advancement of large-scale projects. Whether it is the water supply and drainage pipes of high-rise buildings, the refrigerant transmission pipes of central air-conditioning systems, or the fire-fighting pipes of large venues, their welding quality and efficiency directly affect the overall progress of the project.

Traditional manual welding is limited by the speed and stability of manual operation, which not only makes it difficult to cope with the construction period pressure of large-scale pipe welding but also may cause hidden dangers such as subsequent pipe leakage due to uneven welding.

However, high-speed welded pipe machines, through batch and continuous welding operations, can not only complete the connection of a large number of pipes in a short time but also ensure that the welding quality of each joint meets the standards, laying a foundation for the safe delivery and long-term stable operation of construction projects.

The petroleum and chemical industry has more stringent requirements for pipe welding. Since most of the media transported are flammable, explosive, or corrosive, the quality of pipe welding joints is directly related to production safety.

The automated control technology of high-speed welded pipe machines can achieve accurate reproduction of welding parameters, avoiding quality fluctuations caused by factors such as emotion and fatigue in manual welding.

At the same time, their efficient working rhythm can meet the welding needs of long-distance and multi-specification pipes in petrochemical projects. Whether it is the process pipes in refineries or the long-distance transmission pipes for oil and gas, high-speed welded pipe machines can ensure the corrosion resistance and pressure resistance of the joints, building a solid defense for the safe and stable operation of the entire production system.

In the field of shipbuilding, high-speed welded pipe machines also show irreplaceable value. The internal pipe system of a ship is complex, including fuel pipes and cooling water pipes of the power system, as well as water supply and drainage pipes of the living system.

There are many pipes with various specifications, and the welding space is often limited. Traditional manual welding is difficult to operate in narrow spaces, with low efficiency and difficulty in ensuring the consistency of welding joints. However, high-speed welded pipe machines, with their compact structure design and flexible operation mode, can adapt to complex working conditions in shipbuilding, quickly complete the welding of pipes of different specifications, which not only greatly shortens the assembly cycle of the ship’s pipe system but also reduces the safety risks caused by pipe failures during ship navigation through stable welding quality.

In summary, as a modern welding machine integrating high efficiency and reliability, high-speed welded pipe machines, with their unique working principles, can accurately meet the welding needs of different fields.

Their in-depth application in construction, petroleum, chemical, shipbuilding and other industries not only promotes the improvement of production efficiency in these fields but also plays an irreplaceable role in ensuring project quality and reducing safety risks, becoming an important machine force supporting the technological upgrading and industrial development of related industries.

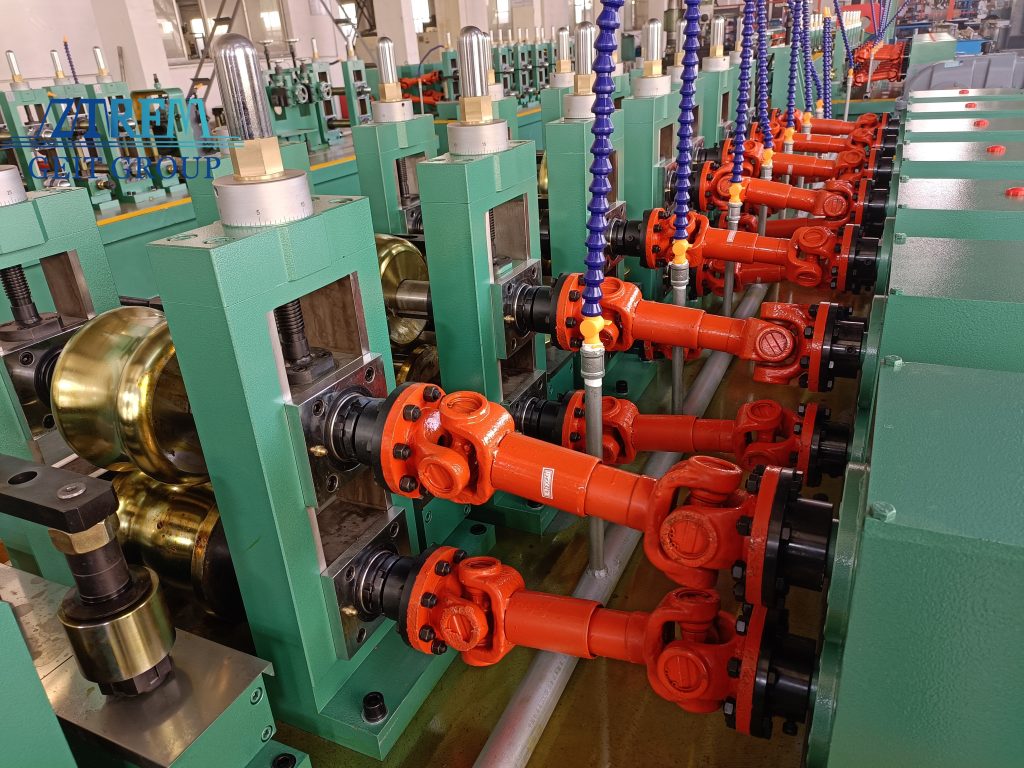

Some spare parts