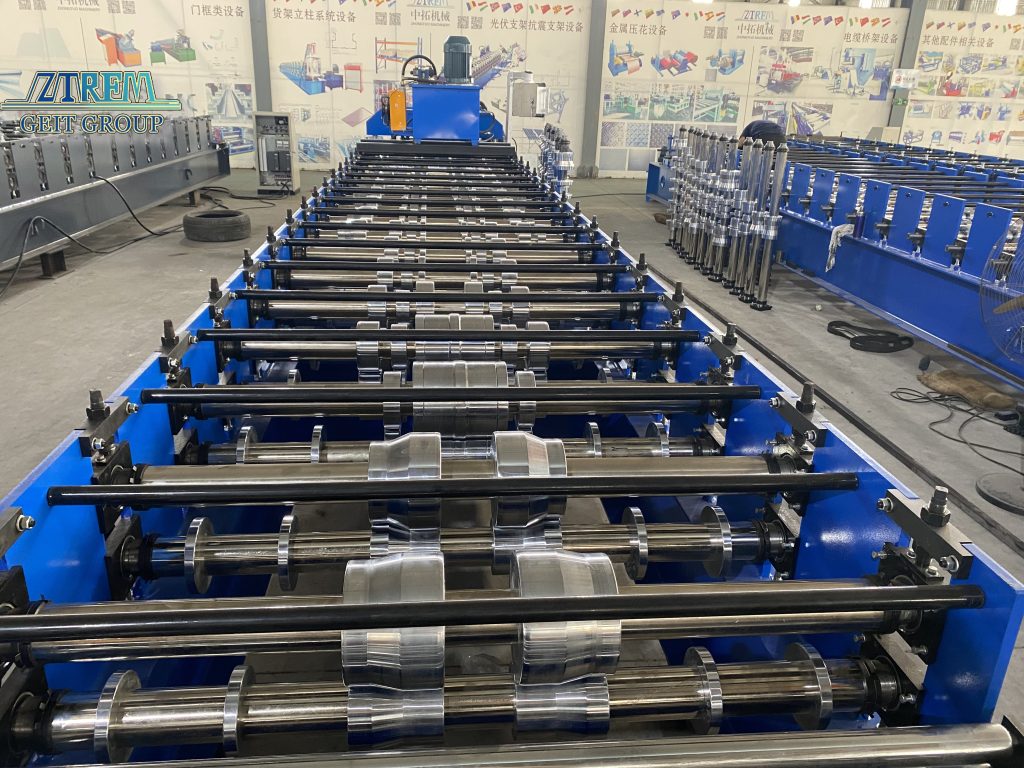

Finished IBR Wall Panel product testing

Introduction of the IBR Wall Panel Roll Forming

The IBR wall panel roll forming machine is an industrial equipment specialized in manufacturing IBR wall panels. As a key production tool in the field of metal enclosure structures, its technical system integrates applications from multiple disciplines such as mechanical transmission, hydraulic control, and electrical automation.

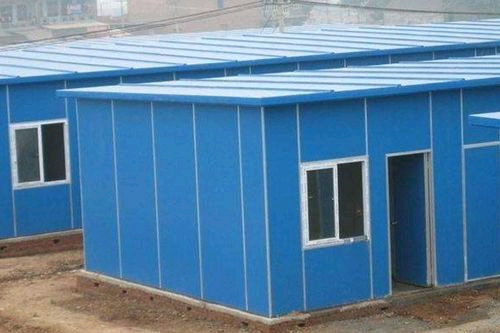

IBR wall panels, a typical product of profiled metal sheets, serve as core components in building envelope systems. They are widely used in roofing and wall cladding projects for industrial plants, logistics warehouses, commercial complexes, and residential buildings. This material is based on hot-dip galvanized or aluminum-zinc coated steel sheets, with high-performance organic coatings like polyester (PE) and fluorocarbon (PVDF) applied through roller coating. It boasts excellent weather resistance, waterproofness, and decorative properties, with parameters such as wave height, wave spacing, and effective coverage width determining its actual performance.

A complete production line of the IBR wall panel roll forming machine usually consists of a coil uncoiler, hydraulic shearing machine, multi-pass roll forming machine, fixed-length cutting device, and PLC intelligent control system. The coil uncoiler adopts an unwinding and expanding structure to ensure stable feeding of color steel coils; the shearing machine uses precision blades and a hydraulic drive system to achieve fixed-length cutting of sheet materials; the forming machine processes flat sheets into trapezoidal cross-sections with specific geometric shapes through continuous roll forming by multiple sets of upper and lower rollers. During the operation of the equipment, the PLC control system monitors process parameters such as feeding speed, forming status, and cutting accuracy in real-time.

Integrating advanced technologies such as servo motor drive, photoelectric positioning, and automatic deviation correction, this equipment enables full-process automated production, including automatic feeding of raw materials, continuous roll forming, and precise fixed-length cutting. Thanks to the modular design of the forming roller sets, it can quickly switch to produce different types of IBR wall panels, with a production efficiency of 15-25 meters per minute—more than three times that of traditional processes. It is particularly suitable for large-scale standardized production needs in industrialized building systems. In addition, the equipment is equipped with a tension control system and straightening device, which can effectively eliminate processing stress in the sheets and ensure the flatness and dimensional accuracy of the product surface.

Machine parameters

|

Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:1220mm/1450mm(customized as drawing)

|

||

|

Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(give you as free)

|

||

|

Main body

|

Roller station

|

18 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

12500*1800*1600(customize)

|

|||

|

Weight

|

10.5T

|

|||

|

Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Application of the machine

Recommended related machine