Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness(0.4-0.7mm) Width(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Ordinary decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

10-20 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive chain

|

1.2inch(As your requirement)

|

|||

|

Dimension(L*W*H)

|

10000*1600*1600(customize)

|

|||

|

Weight

|

4-6T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Power

|

7.5KW

|

||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Product Description:

The working principle of the trapezoid roofing sheet machine is to drive the reducer to rotate through a motor, and then use transmission devices such as chains or belts to make the upper and lower tile molds move towards each other within a certain distance, thereby pressing the metal sheet into the shape of a trapezoidal roof tile.

Main components:

1.Material release device: used to place metal sheet coils to be processed, usually equipped with an uncoiler.

2.Forming system: including multiple rollers, the metal sheet is gradually pressed into a trapezoidal shape as it passes through these rollers.

3.Post forming cutting device: used to cut the formed trapezoidal roof tiles to the required length.

4.Control system: Generally, PLC control system is used to achieve automated production.

Product features:

1.High degree of automation: capable of automatically completing processes such as raw material feeding, forming, cutting, etc., improving production efficiency.

2.High production efficiency: Some equipment can achieve a production speed of 35 meters per minute.

3.Stable product quality: The trapezoidal roof tiles produced have a smooth and beautiful appearance, with high dimensional accuracy.

Application scenarios:

- Industrial plant:

The roof tiles produced by the trapezoid roofing sheet machine are widely used in the roof production of industrial plants. This type of roof tile has the characteristics of high strength, good weather resistance, and long service life, which can meet the strict requirements of industrial plants for roof materials. In addition, the installation of trapezoidal roof tiles is convenient, the construction speed is fast, and it can effectively shorten the construction period.

- Warehouse:

In warehouse buildings, trapezoidal roof tiles are also widely used. Its good waterproof performance and large roof slope design are conducive to the rapid discharge of rainwater and the avoidance of water accumulation problems. Meanwhile, the aesthetic appeal and durability of trapezoidal roof tiles also make them an ideal choice for warehouse roofs.

- Gymnasium:

Large public buildings such as sports arenas have high requirements for the strength and aesthetics of roof materials. Trapezoidal roof tiles not only provide sufficient structural strength, but also meet the requirements of building exterior design. Its unique trapezoidal design and excellent drainage performance make it outstanding in the application of roofs in sports venues.

- Exhibition Hall:

The roof of the exhibition hall needs to have good waterproof performance and high aesthetics to ensure the safety and display effect of the internal exhibits. The waterproof performance and appearance design of trapezoidal roof tiles make them an ideal choice for exhibition hall roofs.

- Housing and simple steel sheds:

The roof tiles produced by the trapezoid roofing sheet machine are also suitable for the roof production of housing and simple steel sheds. Its lightweight design and excellent weather resistance make it perform well in these application scenarios.

Product advantages:

- High structural strength:

The trapezoidal design gives it good structural strength and stability. - Good weather resistance:

Color coated steel plates with galvanized steel plates as substrates are usually used, which have good corrosion resistance. - Good aesthetics:

It has a good appearance and can give buildings more colors.

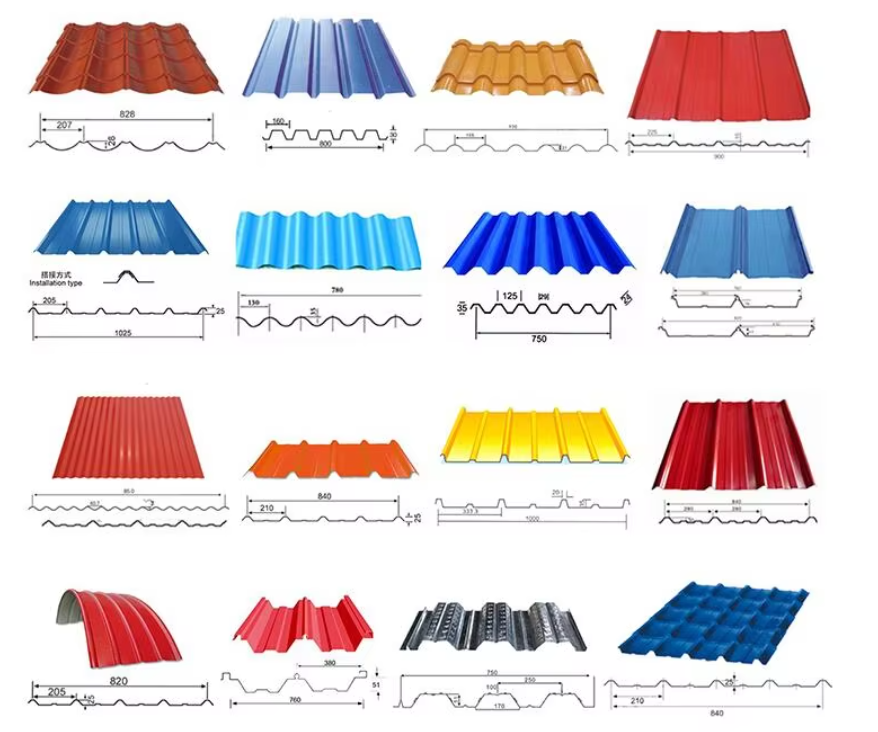

Products Display: