Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

Stainless steel/galvanized steel/carbon steel

|

Thickness:0.5-3mm Width:max 1500mm(Support customization)

|

||

|

2.Leveler

|

Leveling roller

|

9 rollers,up 4 down 5

|

||

|

Roller diameter

|

120mm

|

|||

|

Power

|

5.5kw

|

|||

|

3.Main body

|

Embossing roller diameter

|

450mm

|

||

|

Embossing roller material

|

9cr2si

|

|||

|

Power

|

15kw

|

|||

|

Drive

|

By gear

|

|||

|

Speed

|

0-10m/min

|

|||

|

Dimension(L*W*H)

|

10500*2200*1800(customize)

|

|||

|

Weight

|

11.5T

|

|||

|

4.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

5.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

6.Table

|

Receive table

|

Length:3 meters

|

||

Product Introduction:

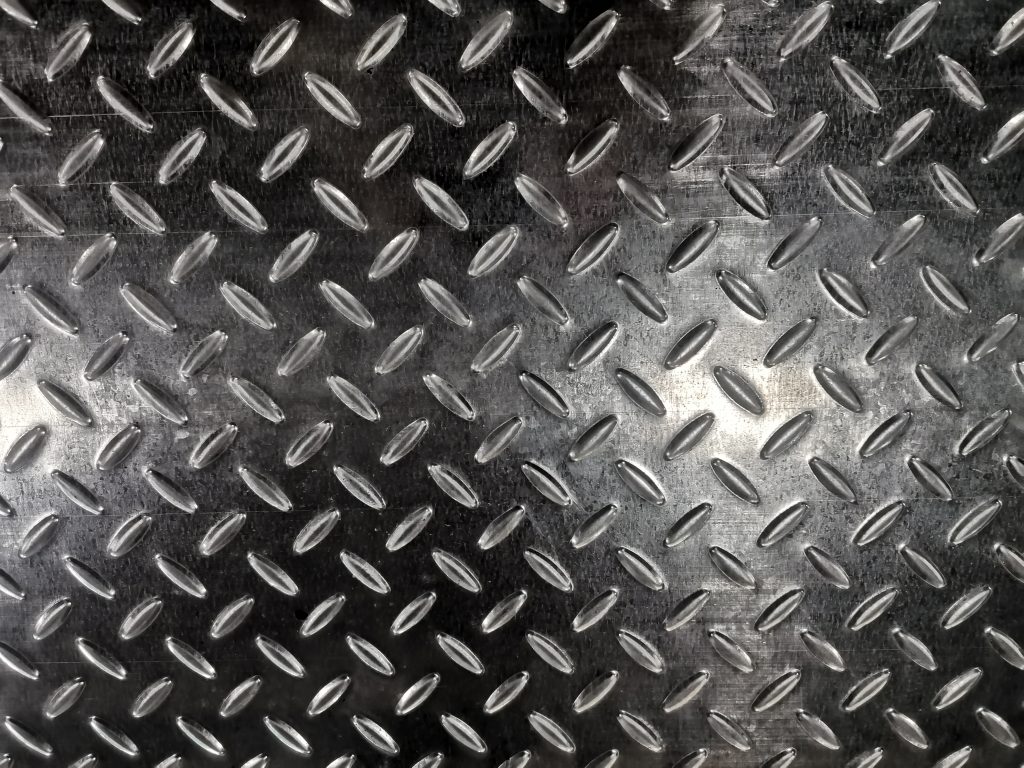

The main function of a metal embossing machine is to imprint various shapes and patterns on the metal surface, thereby enhancing the decorative and functional properties of metal products. Specifically, metal embossing machines can create various patterns by changing different indentation molds, suitable for surface decoration of products such as furniture, cars, and pipes. In addition, metal embossing machines can also be used to process color steel aluminum coils, make metal carved boards, etc.

In the world of metal processing, metal embossing machine is an indispensable equipment, which can leave a variety of exquisite patterns and patterns on the surface of metal materials, giving metal a new texture and beauty, and is widely used in many industries.

Metal embossing machine is a special equipment for embossing metal materials. It exerts a certain pressure on metal plates, strips, etc. through the cooperation of the upper and lower molds, so that the metal surface is plastically deformed, so as to form the desired pattern. Compared with other types of embossing machines, metal embossing machines need to adapt to the characteristics of high hardness and high strength of metal materials in terms of design and performance, with stronger pressure output and more stable operating state.

Notable features:

Metal embossing machines have many distinctive features. First, strong pressure output is one of its core features. Due to the high hardness of metal materials, it requires greater pressure to deform the surface to form patterns, so metal embossing machines are usually equipped with a strong power system, which can provide enough pressure to ensure that the patterns are clearly and completely pressed on the metal surface. Second, high-precision mold processing and coordination. Metal embossing has high requirements for the accuracy of the pattern, which requires the mold to have extremely high processing accuracy, and the cooperation between the upper and lower molds must also be very accurate, so as to ensure that the embossed pattern size is accurate and the pattern is clear. Third, good stability and durability. In the process of metal embossing, the equipment bears a large load, so the body structure of the metal embossing machine is usually made of high-strength materials, and the parts are also carefully designed and processed to ensure that the equipment can operate stably and prolong the service life under long-term high-intensity work. Fourth, a wide range of adaptability. It can emboss metal materials of different thicknesses and materials, such as steel plates, aluminum plates, copper plates, etc., and can press out a variety of different patterns and patterns according to the needs to meet the diverse processing needs.

Application Scenarios:

In terms of application fields, metal embossing machines are found in many industries. In the building decoration industry, metal embossed panels are widely used in wall decoration, ceiling decoration, elevator decoration, etc. The embossed metal plate has a unique texture and texture, which can add a fashionable and high-end atmosphere to the building, such as the lobby wall of some shopping malls and hotels is embossed metal plate, which is both beautiful and durable. In the automobile manufacturing industry, the metal embossing process is used for the decoration of some parts of the automobile, such as the metal embossing trim strip on the door trim panel, which not only improves the texture and grade of the car interior, but also plays a certain decorative and anti-skid role. In the home appliance industry, the shell of many household appliances will adopt metal embossing process, such as the panel of refrigerators and washing machines, which can make the appearance of household appliances more beautiful and unique, and increase the market competitiveness of products. In the handicraft production industry, the metal embossing machine is even more skilled, able to produce a variety of exquisite metal handicrafts, such as metal paintings, metal ornaments, etc., these handicrafts with unique patterns and textures, deeply loved by consumers. In short, with its unique performance and wide range of applications, metal embossing machine plays an important role in the field of metal processing, providing strong support for the diversification and high-quality development of metal products. With the continuous advancement of technology, metal embossing machines are bound to show their value in more fields.