Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL

|

Material Thickness:24/26 Gauge (0.3-0.6 mm)

Width:43inch(1092mm)

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

Dimension(L*W*H)

|

9.5m*1.65m*1.5m

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

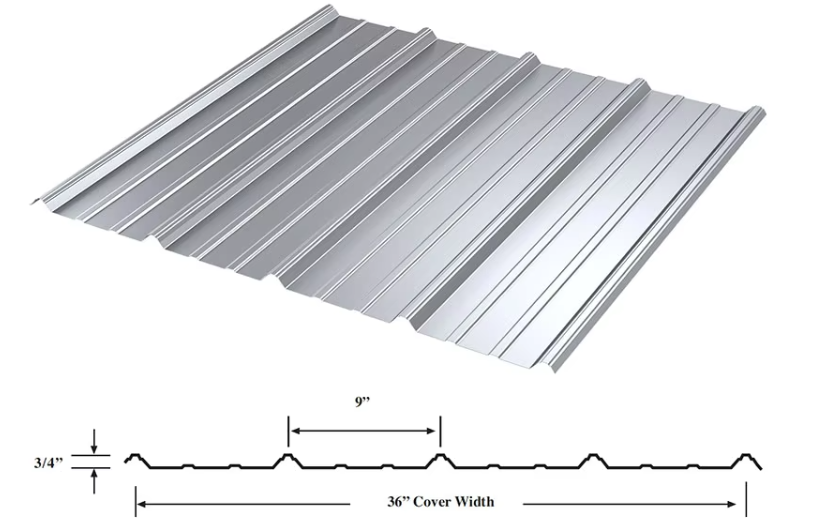

As the construction industry continues to grow, so does the demand for roofing materials. Traditional tiles are gradually being replaced by more efficient and durable metal tiles. Among the many metal tile production equipment, the trapezoidal roof tile machine has become the preferred equipment for many construction enterprises because of its high efficiency, stability and strong adaptability. Trapezoidal roof tile machine is a kind of cold-formed equipment specially used for the production of trapezoidal section metal tiles. It processes metal coils (such as galvanized steel sheets, color-coated steel sheets, aluminum sheets, etc.) into roofing tiles with trapezoidal corrugations through roll forming technology. This tile type has the advantages of good drainage performance, high structural strength, convenient installation, etc., and is widely used in roofing systems such as industrial plants, warehouses, civil buildings, and agricultural greenhouses.

Main characteristics:

1.Efficient and automated production

Modern trapezoidal tile machine is equipped with PLC control system, which can realize fully automatic production, including automatic feeding, forming, shearing, counting and other functions, which greatly improves production efficiency and saves labor costs.

2.High molding accuracy

High-precision roller molds are used to ensure that the size of each tile is consistent, the lap is tight, the overall appearance after installation is beautiful, and the waterproof performance is superior.

3.Adaptable to a wide range of materials

Metal sheets of different thicknesses (usually 0.3mm-0.8mm) and materials can be customized according to customer needs to meet the needs of different construction projects.

4.The structure is sturdy and has a long service life

The whole machine is welded with high-strength steel, after heat treatment and high-precision processing, the equipment runs stably and has low maintenance cost.

5.Tile type and size can be customized

The wave height, wave distance, effective width and other parameters of the trapezoidal tile can be customized according to customer requirements to meet the diversified market demand.

Technology Development Trends:

1. Intelligent upgrading:

In the future, the trapezoidal roof tile machine will develop in depth in the direction of intelligence. The equipment will be equipped with more advanced sensors and intelligent control systems to realize fully automatic monitoring and control of the production process. For example, sensors monitor the thickness of the sheet, material hardness and other parameters in real time, and automatically adjust the pressure and speed of the forming roll to ensure consistent product quality. The intelligent control system can also automatically optimize the production process according to the needs of the production order, reasonably arrange the operation time and maintenance plan of the equipment, and further improve the production efficiency and reliability of the equipment. At the same time, the equipment will have remote monitoring and diagnosis functions, and manufacturers can remotely monitor and manage the equipment through the network, solve the problems in the operation of the equipment in a timely manner, and reduce the cost of after-sales service.

2.High-precision and high-performance improvement:

With the continuous improvement of the construction industry’s requirements for the quality and performance of roofing tiles, trapezoidal roof tile machines will continue to carry out technological innovation in terms of high precision and high performance. In terms of molding technology, more advanced roll forming processes will be developed to further improve the dimensional accuracy and surface quality of roofing tiles and reduce defects in the molding process. The key components of the equipment, such as forming rollers and transmission parts, will be made of new materials with higher strength and more wear resistance to improve the service life and stability of the equipment. At the same time, by optimizing the structural design of the equipment, the operation speed and production efficiency of the equipment are improved, and the production capacity is further improved on the premise of ensuring product quality.