Introduction of metal supermarket shelf back panel machine

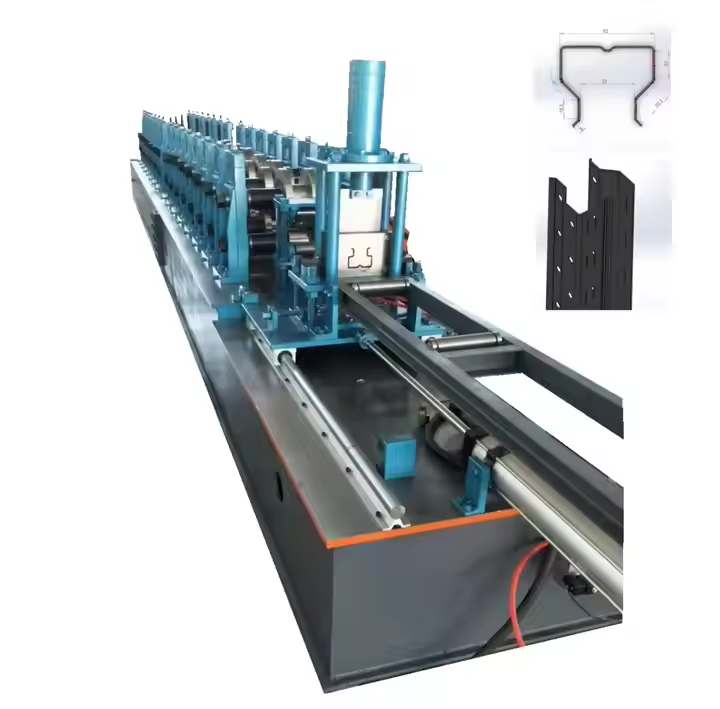

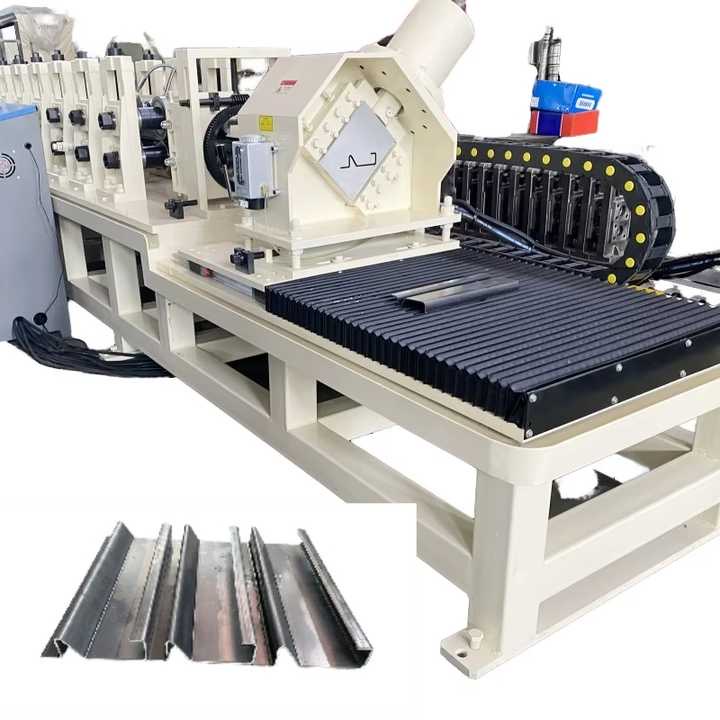

The forming machine for supermarket shelf back panel pallets is extensively utilized in the cold-rolling forming process of various profiles, such as those applied in storage racks, heavy-duty shelving systems, medium-duty racks, and high-density automated storage structures. This specialized equipment is engineered to meet the stringent requirements of the warehousing and logistics industry, ensuring the production of high-quality and durable shelf components.

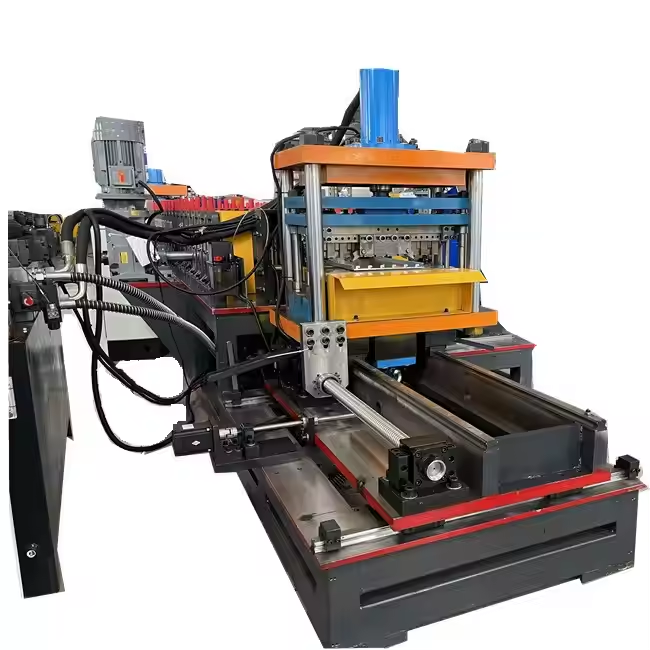

The shelf back panel pallet forming machine developed by ZTRFM Shelf features an innovative integrated design. By incorporating multiple manufacturing processes, including sheet feeding, roll forming, cutting, and shaping, into a unified system, it effectively streamlines the production workflow. This not only minimizes the need for multiple standalone machines but also reduces material handling time and potential errors between different production stages, thereby achieving a substantial boost in overall production efficiency.

Employing state-of-the-art Computer Numerical Control (CNC) technology, the equipment provides unparalleled precision in the manufacturing process. It enables operators to accurately program and control critical parameters, such as the length, width, thickness, and curvature of the shelf back panel pallets. The advanced control system ensures consistent dimensional accuracy and repeatability, meeting the strict quality standards required for modern warehousing applications. Moreover, the machine is equipped with real-time monitoring and adjustment functions, which can detect and correct any deviations during the production process, guaranteeing the production of defect-free products.

When utilized for manufacturing shelf profiles, this pallet forming machine offers a multitude of significant advantages. From a cost perspective, its high-efficiency production process and optimized material utilization contribute to a substantial reduction in production costs.

The ability to produce large quantities of components in a short period, combined with minimized material waste, translates into enhanced cost-effectiveness for manufacturers. In terms of production speed, the automated and continuous operation of the machine far surpasses traditional manufacturing methods, enabling rapid turnaround times for orders.

Additionally, the machine is designed to work with a variety of environmentally-friendly materials, such as recycled steel and low-carbon alloys. This not only aligns with the global trend towards sustainable manufacturing but also allows manufacturers to meet the increasing demand for green products in the market.

In addition to its inherent capabilities, the equipment is highly adaptable and can be seamlessly integrated with automated manufacturing systems, including robotic handling systems, conveyor belts, and intelligent warehouse management systems. This integration further automates the production process, reducing the reliance on manual labor and minimizing human error. By enhancing the degree of automation, enterprises can improve production flexibility, respond more quickly to market demands, and ultimately gain a significant competitive advantage in the highly competitive storage and shelving industry.

Specification of metal supermarket shelf back panel profiles

|

Item |

Specification | |||

|

Machine specification |

Thickness | 0.5-0.6mm | ||

| Coil inner | Inner diameter of 450~500mm, outer diameter of 1200mm | |||

| Working speed |

8-10m/min equipment working line speed |

|||

| Machining length | according to requirements | |||

| Machining accuracy | L<1000mm:±0.5mm | |||

| Forming Width | 99mm 199mm 299mm 399mm 499mm | |||

| Forming section | on drawing | |||

|

Power |

total power | ≤30KM | ||

Features of Supermarket Shelf Back Panel Pallet Forming Machine Equipment

1. Fully Automatic Intelligent Control

The supermarket shelf back panel pallet forming machine is equipped with a state-of-the-art Programmable Logic Controller (PLC) system for comprehensive, full – process intelligent control. This advanced control mechanism significantly enhances the automation level of the equipment.

2. Robust and Durable Structural Design

The forming frame of the machine is meticulously constructed by welding high – grade channel steel. This structural design endows the equipment with exceptional strength and a prolonged service life. The channel steel, renowned for its high load – bearing capacity and resistance to deformation, provides a stable foundation for the entire forming process.

During the high – intensity production of supermarket shelf back panel pallets, the robust frame effectively withstands mechanical stresses and vibrations, maintaining the equipment’s stability. This not only ensures the consistent quality of the formed pallets but also reduces the frequency of maintenance and repair, thereby enhancing the overall operational efficiency of the production line.

3. High – Quality Materials

– Reel: The reel, a crucial component of the forming machine, is fabricated from 40Cr steel. This alloy steel undergoes a meticulous quenching and tempering treatment process. As a result, its hardness reaches HB280, which offers excellent mechanical properties such as high strength and good toughness.

4. Transmission System

The equipment offers flexibility in its transmission structure, allowing users to choose between a gearbox transmission system and a chain transmission system. The gearbox transmission, characterized by its high transmission efficiency and precise speed control, is ideal for applications requiring stable and accurate power transmission. It can effectively reduce power loss during the transmission process and ensure smooth operation of the forming machine. On the other hand, the chain transmission system is known for its high load – carrying capacity and durability.

It can withstand heavy – duty working conditions, making it suitable for high – intensity production environments. Regardless of the chosen transmission method, both options are designed to ensure the stability of the transmission process, preventing power fluctuations and slippage. This stability is essential for maintaining the consistent quality and production efficiency of supermarket shelf back panel pallets.

Recommended related machine