Product positioning and core values

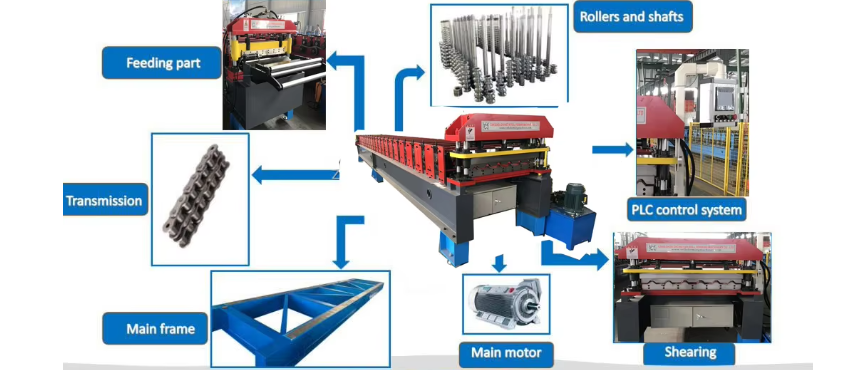

USA Hot Sale Metal Roof PBR R Panel Roll Forming Machine is an intelligent mechanical device dedicated to producing trapezoidal cross-section metal roof panels, widely used in large-span buildings such as industrial plants, logistics warehouses, sports venues, etc. Its core value lies in:

• High strength and lightweight:

By using trapezoidal corrugated design, the bending resistance of the board is improved (bearing capacity is increased by more than 30%), while reducing material usage.

• Quick installation:

Standardized production matched with modular construction, with a daily laying area of over 2000 square meters.

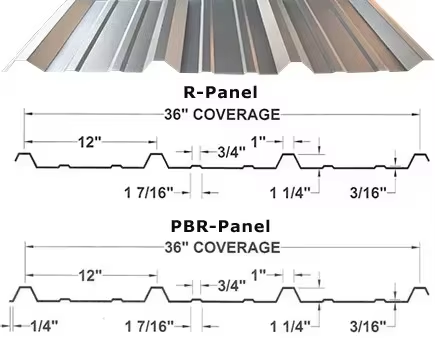

Pattern diagram:

Technical highlights of USA Hot Sale Metal Roof PBR R Panel Roll Forming Machine

1. Intelligent molding technology

Fully automatic roll forming: using a high-precision servo system, the sheet forming error is ≤ 0.2mm, and it supports customized ripple height (25-150mm).

Multi functional integration: One piece completion of unwinding, punching, cutting, and molding, reducing manual intervention.

2. Material adaptability

Compatible with galvanized steel plates, aluminum magnesium manganese alloys, stainless steel, etc., with a thickness range of 0.4-1.5mm.

Optional anti-corrosion coating (PVDF, PE) process, suitable for coastal, chemical and other corrosive environments.

Product Attributes:

|

1.Formed Material

|

Material Thickness

|

0.3-0.8mm

|

||

|

2.Main body

|

Roller station

|

19 rows

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 20mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

3.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

4.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

5.Voltage

|

480V/440v/600v/240v 60Hz 3Phase

|

As your requirement

|

||

|

6.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

7.Forming Speed

|

0-15m/min

|

45ft/min

|

||

Application scenarios

• Shorten the construction period of industrial steel structure factories and workshops by 30% and reduce comprehensive costs by 20%

• Logistics and warehousing large warehouses, cold chain centers improve roof sealing and reduce energy loss

• Public facilities such as airport terminals and sports halls enhance their seismic and wind resistance performance, extending their service life