Working flow

https://www.youtube.com/watch?v=Di5QPz8295s&list=PLUcovtm6imwsLlYudJQeUT_0IGLt_TxUf

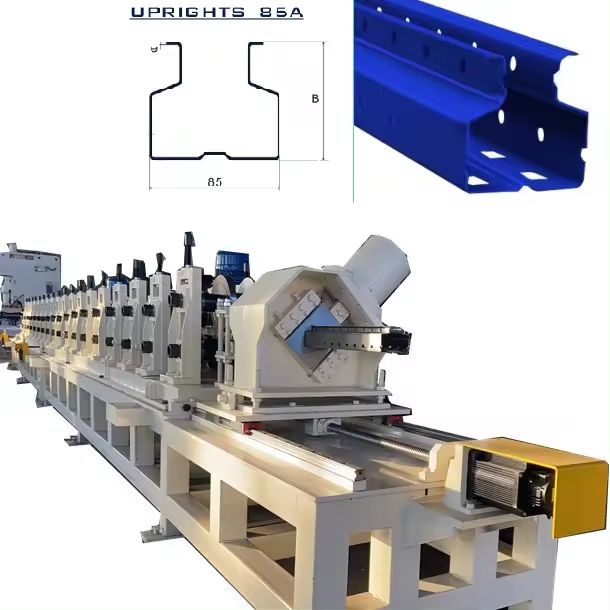

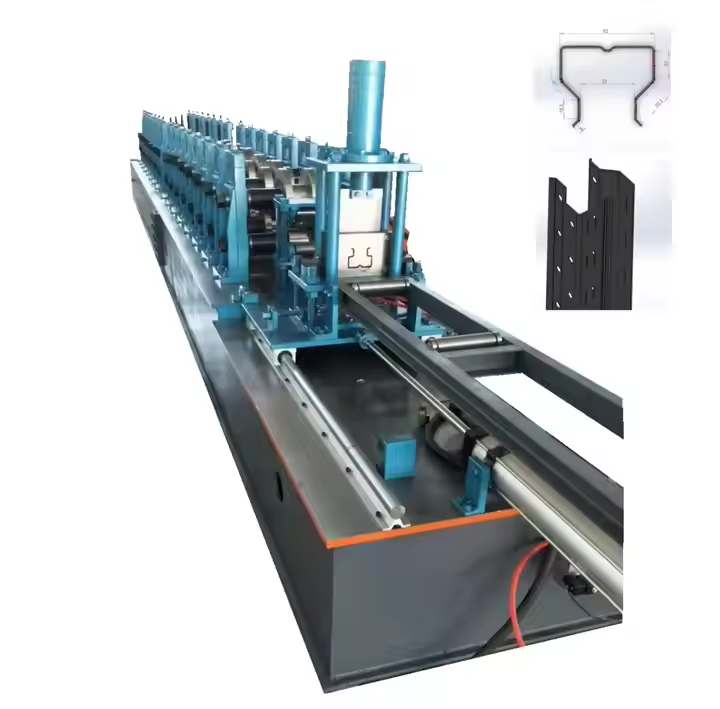

Rack System Making Machine

A rack system machine is a specialized piece of equipment designed for the production of shelves. It stands out for its remarkable efficiency, high precision, and user-friendly operation. Thanks to its intelligent control system, operators can easily set parameters, and the intuitive touch – screen control panel enables quick mastery without the need for extensive training.

With an integrated design that combines multiple processes such as automatic feeding, punching, shearing, bending, and forming into one device, it can complete the production of an entire shelf in a single run, significantly enhancing productivity compared to traditional methods. Leveraging advanced numerical control technology, the machine ensures accurate control over the size and shape of shelves, and its built – in measurement and detection systems promptly correct any deviations during production, guaranteeing consistent quality.

Machine parameters of Rack System Making Machine:

| Formed Material | PPGI,GI,AI | Thickness:1.5-2.7mm | ||

| Decoiler | Hydraulic automatic decoiler | will give you as free | ||

| Main body | Roller station | As your requirement | ||

| Diameter of shaft | As your requirement | |||

| Material of rollers | 45# steel, hard chrome plated on the surface | |||

| Machine body frame | Metal steel welded | |||

| Drive | gearbox transmission | |||

| Dimension(L*W*H) | customize | |||

| Weight | About 75T | |||

| Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

Advantages of the machine

1. Simple Operation

The rack system machine is equipped with an intelligent control system. Operators only need to set parameters simply to complete the entire production process. Most rack system machines are also equipped with touch – screen control panels, which are intuitive and easy to understand. Without the need for specialized training, operators can quickly get up to speed.

2. High Efficiency

The rack system machine features an integrated design, integrating multiple processes into a single device. Through processes such as automatic feeding, punching, shearing, bending, and forming, it can complete the production of an entire shelf in one go. Compared with traditional processes, the production efficiency of the shelving forming machine has been significantly improved.

3. High Precision

The machine adopts advanced numerical control technology. With high equipment precision and good stability, it can accurately control the size and shape of the shelves.

Through the built – in measurement and detection system of the equipment, it can promptly monitor deviations during the production process and make corresponding adjustments to ensure that the quality of the produced shelves meets the standards.