Hot Sale TR35 Trapezoid Metal Roofing Sheet Roll Forming Machine with Automatic Palletizing , also known as trapezoidal tile pressing machine or cold bending trapezoidal plate forming machine, is an automated cold bending forming equipment designed for mass production of metal trapezoidal roof tiles. The core relies on multiple continuous roll forming processes to process various metal coils such as color coated coils, galvanized coils, aluminum magnesium manganese coils, stainless steel coils, etc. into trapezoidal roof tile products with standardized specifications and regular shapes in one go. It is the core supporting equipment for modern metal enclosure systems (roofs, walls) production. This device integrates the full process functions of feeding, leveling, forming, fixed length cutting, counting and discharging, without the need for complex manual intervention, achieving integrated production from raw materials to finished products. It can meet the needs of large-scale mass production and flexibly adapt to customized production of different specifications and materials, balancing efficiency and quality, adapting to the production needs of various building materials production enterprises and steel structure engineering supporting manufacturers, helping enterprises reduce costs and increase efficiency, and enhance core competitiveness.

Application scenario:

• In the field of industrial construction

it is the preferred equipment for factories, warehouses, workshops, and logistics centers. Industrial buildings have extremely high requirements for wind resistance, compression resistance, waterproofing, and corrosion resistance of roofs. The trapezoidal tile structure produced by this product is stable, with a wind resistance load of 0.5kn/m2, suitable for large-span steel structure buildings, and can effectively resist dust and rainwater erosion in industrial environments. At the same time, the mass production capacity can quickly meet the roof laying needs of large industrial plants, helping industrial projects to land quickly and reduce construction costs.

• In the field of civil architecture

it is suitable for roof construction such as villas, residential buildings, resettlement houses, and activity board houses. The trapezoidal tile design is simple and atmospheric, and can be customized with colors and specifications according to the style of residential buildings, combining aesthetics and practicality. It can not only improve the waterproof and thermal insulation performance of residential roofs, extend the service life of roofs, but also adapt to the aesthetic needs of different residential scenes such as rural self built houses and urban villas. At the same time, the flexible customization ability of equipment can meet small-scale and personalized production needs, and adapt to the diverse needs of residential construction.

• In the field of commercial and public buildings

it covers places such as shopping malls, office buildings, sports venues, schools, hospitals, etc. This kind of building has a large roof area and high construction standards. It has strict requirements on the specification uniformity and installation convenience of tiles. The trapezoidal tiles produced by this product have standard specifications and tight splicing, which can greatly improve the efficiency of roof construction. At the same time, it has sound insulation, heat insulation and anti-aging properties, which can meet the long-term use needs of commercial buildings, and help to create a high-quality and durable roof system for public buildings.

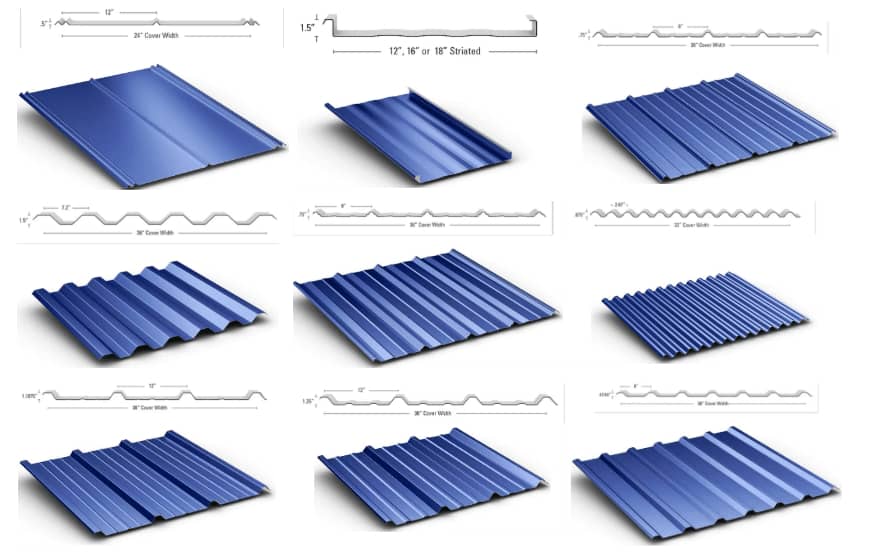

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

GI,Steel

|

Thickness:0.3-1.0mm Width:1250mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

22 rows(As your requirement)

|

||

|

Diameter of shaft

|

85mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Core Features: Supported by four major advantages, creating industry benchmarks

Compared to traditional tile making equipment, this product is guided by precision, efficiency, intelligence, and durability. Each feature is tailored to the actual production needs, breaking through industry pain points with technology and demonstrating its hardcore strength

1. Precise molding, worry free quality.

Adopting PLC numerical control system combined with servo motor drive, the entire process is digitally controlled, which can achieve precise control of trapezoidal tile peak height, peak distance, and board length, with an error of ≤± 0.5mm. The splicing and interlocking are tight, and the hidden dangers of roof water seepage and rain leakage are eliminated from the source; The mold is made of Cr12MoV high-strength alloy material, which has a hardness of HRC58-62 after vacuum quenching treatment. It is wear-resistant and durable, with a cumulative service life of over 80000 times, far exceeding that of ordinary molds by more than three times. The formed tile surface is smooth without scratches or waves, with excellent appearance and waterproof performance. It can be directly put into construction use without the need for secondary polishing.

2. Efficient and energy-saving, significantly reducing costs.

Equipped with servo tracking cutting technology, the forming machine can complete fixed length cutting without stopping, without start stop loss or production interruption, and the production efficiency is increased by more than 20% compared to traditional equipment; The production speed of the equipment can be flexibly adjusted, with a range of 8-15m/min. The daily output of a single equipment (8-hour working system) can reach 3000-4500 square meters, which is more than 10 times more efficient than traditional manual processing and greatly shortens the production period; Equipped with a 7.5-15kw energy-saving motor, the power consumption of traditional equipment is reduced by 30%. Working for 8 hours a day can save over 10000 yuan in electricity bills per year. At the same time, the standby mode automatically enters energy-saving mode, further reducing operating costs; Optional automatic stacking, automatic film covering, and automatic palletizing devices can be used to achieve unmanned assembly line operations of “rolling out board packing”, saving manpower, space, and management costs.

3. Intelligent and convenient, quick to get started.

Adopting PLC touch screen human-machine interface, the operation is simple and easy to understand. The entire process of parameter preset, automatic unwinding, forming, fixed length cutting, counting, fault self checking, etc. is automatically completed. Novices can operate proficiently in one day; Support batch length setting, output statistics, and data storage functions, facilitating production management and reconciliation, significantly reducing manual intervention and operational error rates; The key parts of the fuselage are reserved with maintenance windows, and lubrication points are centrally arranged. Daily maintenance only requires regular addition of lubricating oil and cleaning of mold impurities. The universality of vulnerable parts is strong, and replacement is simple without the need for professional tools, greatly reducing equipment downtime for maintenance.

4.Durable and adaptable, flexible and diverse.

The fuselage is welded with 16mm thickened Q235 steel plate as a whole, which is annealed to eliminate internal stress. It is equipped with memorial archway type frame+high-strength connection, which has small operating vibration, uniform plate stress, and can operate continuously and stably for 24 hours. The failure rate is less than 0.5%/year, which meets the needs of factory batch production; Support the processing of various metal coils with a thickness of 0.3-1.2mm, compatible with standard coil widths of 1000mm/1200mm, and can quickly switch between mainstream trapezoidal models such as 900/840/850/860. Special specifications support customized development to meet the differentiated needs of different projects and adapt to various installation scenarios for building roofs.