Here is the working video of this machine for everyone to watch:

Product Attributes of Z-shaped beam Roll Forming Machine :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:2-2.5mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

Cr12 with quenched treatment.

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

8500*1200*1500(customize)

|

|||

|

Weight

|

About 8.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20-25m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Product Description:

Automatic Supermarket Storage Shelf Column Z-shaped beam Roll Forming Machine for Warehouse: precision tailoring for intelligent manufacturing

In modern warehousing and logistics systems, shelves serve as the backbone of the storage system, and the manufacturing quality of their core load-bearing components – Z-shaped columns – directly determines the stability of the overall structure. The Z-shaped beam bending forming machine for shelf columns is precisely the “precision tailor” for this key component, which efficiently converts metal sheets into high-strength structural components through cold bending forming technology.

1.High precision and high-strength molding:

(1)Precise section control: Through multiple passes (usually 14 rows of rollers, can also be customized according to your requirements) of progressive cold bending process, ensure that the formed Z-beam has accurate dimensions and consistent shape, meeting the strict tolerance requirements of shelf assembly.

(2) Excellent mechanical properties: Cold bending processing produces work hardening effect on the material, significantly improving the bending and compressive strength and stability of Z-shaped beams, which can be directly used as the core load-bearing structure of shelves.

2.Efficient automated production:

(1)Continuous assembly line operation: integrating processes such as uncoiling, leveling, punching (optional), forming, fixed length cutting, and material receiving to achieve full process automation, with a production speed of up to 9-15 meters per minute.

(2) Flexible adaptation: By adjusting the roller mold and process parameters, it is possible to quickly switch the production of Z-shaped beams of different specifications (such as height 80-300mm, thickness 1-3mm) to meet the needs of multiple varieties.

3.Core structure design and performance:

(1)High rigidity frame and transmission: Adopting an integrated gearbox transmission system (main motor power 11-15kW), matched with bearing steel rollers (Gcr15 material), to ensure stability and durability under high-speed operation.

(2) Precise cutting technology: Equipped with a hydraulic or servo driven shutdown cutting system, the cutting blade material is Cr12 tool steel, ensuring a smooth and deformation free cut.

Machine advantages:

- High production efficiency:

This molding machine adopts automated industrial control technology, which can achieve continuous production from coil loading to single piece molding, greatly improving production efficiency. Compared with traditional decentralized multi process and multi person processing, the entire line only requires one person to operate, reducing labor intensity and lowering labor costs. - Easy to operate:

The equipment has a compact structure design, few components, easy maintenance, small footprint, and saves factory space. When replacing the product, only new data needs to be entered to run and use it, without the need for hardware device modification and settings. - Accurate positioning:

smooth operation, fast material grabbing speed, high efficiency of assembly line work. Programmable settings, speed can be fast or slow, non-standard customized end configuration fixtures, suitable for multi scenario applications. - Strong adaptability:

suitable for production of various specifications, able to meet the special needs of different customers. For example, the fully automatic supermarket shelf column and beam forming equipment is suitable for the production of columns and beams for supermarket shelves.

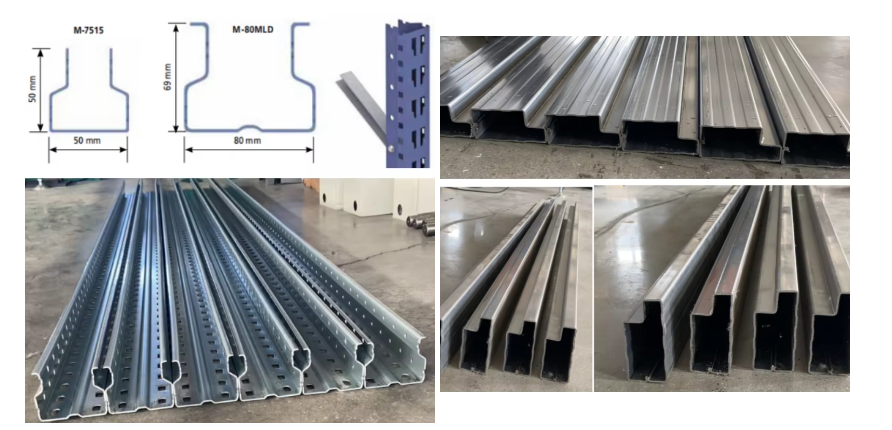

Products Display: