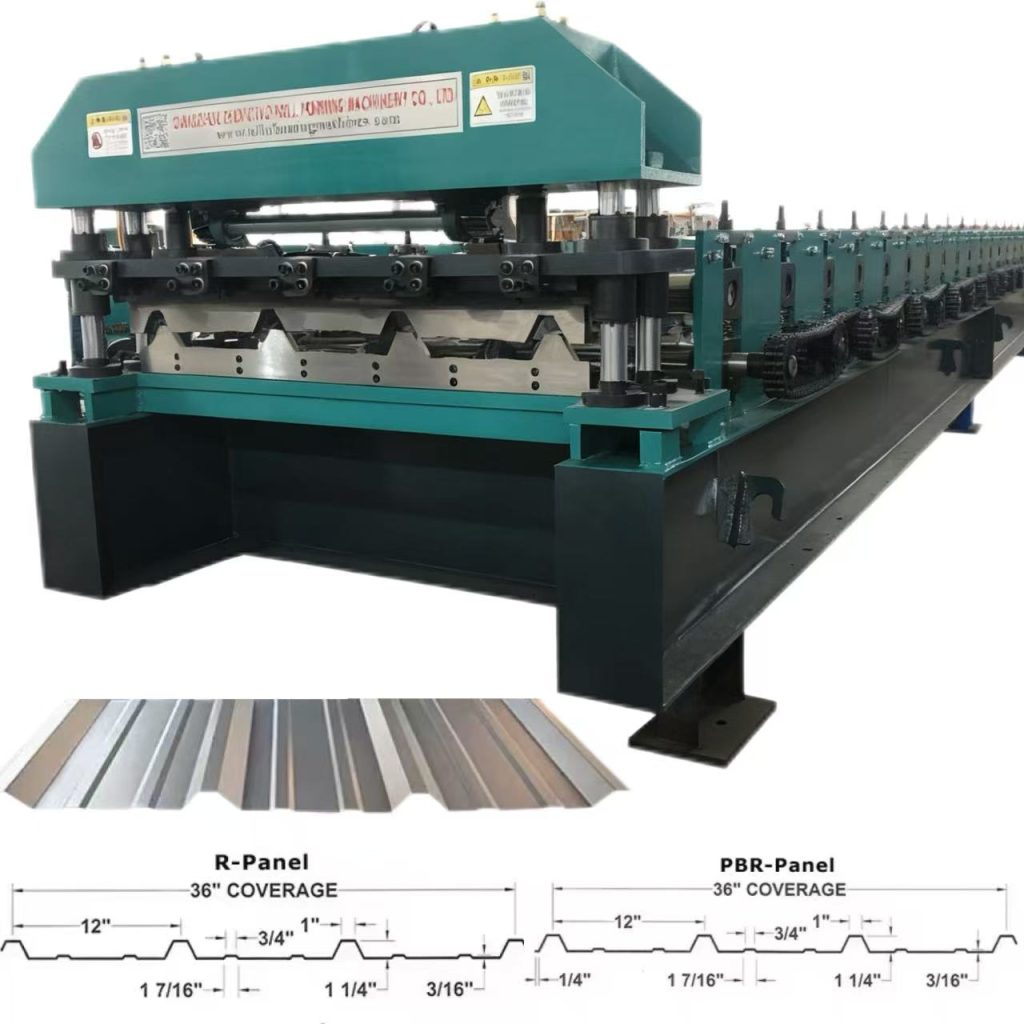

Metal building panel roll forming lines

Metal building panel roll forming lines is to process raw materials such as color coated steel plates, galvanized steel plates, and aluminum alloy plates into trapezoidal roof tiles with the characteristics of “wind resistance, waterproofing, easy installation, and stable stress” through continuous rolling and precise cutting processes, widely serving the efficient production of building roof systems.

Adapt to raw materials

• Material range:

capable of processing color coated steel plates (thickness 0.2-0.8mm), galvanized steel plates (0.3-1.0mm), and aluminum alloy plates (0.5-1.2mm), meeting the anti-corrosion and lightweight requirements of different buildings;

• Raw material form:

Suitable for roll metal sheet (roll diameter ≤ 1200mm, weight ≤ 5000kg), compatible with mainstream industrial coil specifications.

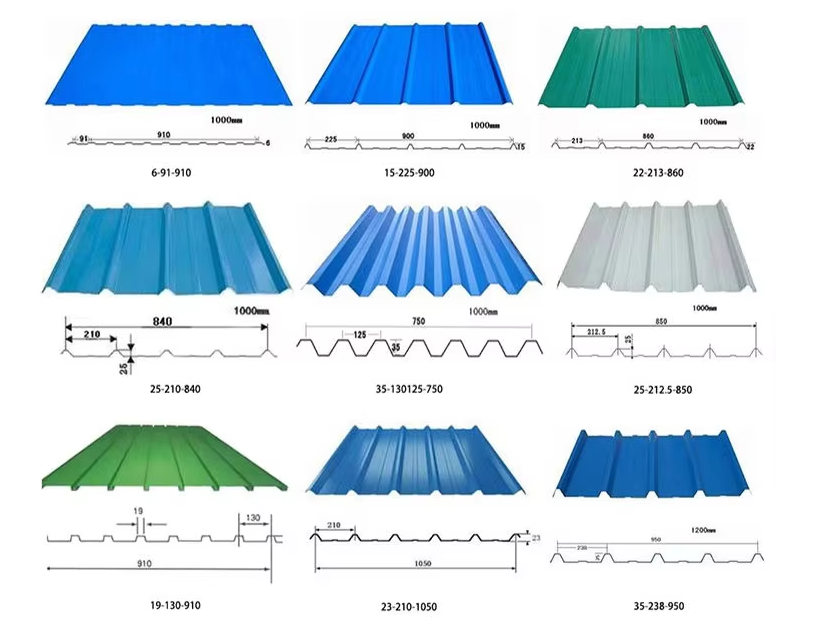

Characteristics of finished tiles

• Structural advantages:

trapezoidal cross-section design, strong sealing during overlapping, and better waterproofing than ordinary flat tiles;

• Customization:

The trapezoidal height (20-80mm) and finished product length (1.5-6m) can be adjusted by replacing the rollers to meet different roof size requirements for industrial and civilian use.

Product Attributes

|

1.Formed Material

|

Material Thickness

|

24-26 gauge |

||

|

2.Main body

|

Roller station

|

19 rows

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350mm H Beam Structure, With 20mm Welded Steel Middle Support Plate.

|

|||

|

Drive

|

gear and Double Chain transmission

|

|||

|

3.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

4.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

5.Voltage

|

480V/440v/600v/240v 60Hz 3Phase

|

As your requirement

|

||

|

6.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

7.Forming Speed

|

0-15m/min

|

45ft/min

|

||