In the field of steel structure building enclosure engineering, trapezoidal roof tiles have become the preferred roofing solution for industrial plants, agricultural facilities, public buildings, and other scenarios due to their core advantages of tight interlocking, wind and pressure resistance, and aesthetic durability. The efficient, precise, and stable Trapezoidal Roofing Sheet Making Machine IBR Roof Tile Machine is the core engine for ensuring project quality, shortening construction period, and reducing costs. We have been deeply involved in the research and production of cold bending forming equipment for many years. With cutting-edge technology, industrial grade configuration, and comprehensive services, we have created Trapezoidal Roofing Sheet Making Machine IBR Roof Tile Machine that has become the trusted choice of countless engineering and production companies, injecting strong impetus into the intelligent upgrading of the construction industry.

Full scene adaptation to meet diverse engineering needs

• In the field of industrial construction

Suitable for the roof and wall enclosure of large-span steel structure buildings such as factories, warehouses, and logistics centers, the trapezoidal tiles produced have a wind load resistance of 0.5kn/m2 and excellent compressive performance, effectively resisting severe weather erosion.

• In the field of agriculture and animal husbandry

Provide waterproof, moisture-proof, and corrosion-resistant enclosure solutions for agricultural greenhouses, greenhouses, and livestock farms. The finished tiles are lightweight (only 3-5kg per square meter) and will not increase the load-bearing burden on the skeleton.

• In the field of public and civil buildings

Can be used in community kiosks, vegetable market ceilings, parking lot canopies, and other scenarios, matched with different colored painted rolls, balancing decoration and practicality.

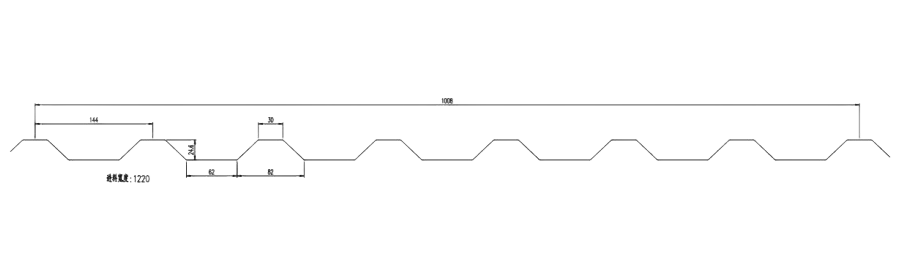

Profile drawing as below:

Supported by core technology, we forge the hardware strength of our equipment

The core competitiveness of equipment comes from the meticulous polishing and technological innovation of every detail. Our Trapezoidal Roofing Sheet Making Machine IBR Roof Tile Machine breaks through industry bottlenecks in all aspects, from molding accuracy and production efficiency to durability and energy saving, achieving the optimal balance between performance and cost.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness(0.3-0.8mm) Width 912mm/1220mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Ordinary decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

21 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive chain

|

1.2inch(As your requirement)

|

|||

|

Dimension(L*W*H)

|

8500*1400*1300(customize)

|

|||

|

Weight

|

9 tons

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Spanish/English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Equipment core advantages:

1.Accurate molding, zero deviation in quality

Adopting a PLC numerical control system combined with servo motor drive to achieve precise control throughout the entire process, the forming size error is ≤± 0.5mm, the peak height and distance of trapezoidal tiles are uniform and consistent, and the joints are tightly interlocked, eliminating hidden dangers such as roof water seepage and rain leakage from the source. The mold is made of Cr12MoV high-strength alloy material, which has a hardness of HRC58-62 after vacuum quenching treatment. It not only has a smooth and scratch free forming surface, but also has a cumulative service life of over 80000 times, more than three times that of ordinary molds, greatly reducing the cost of mold replacement. Equipped with a hydraulic cutting system (optional mechanical cutting), the incision is smooth and free of burrs, and the cutting length can be freely set through the touch screen (500mm-6000mm), with an error of ≤± 1mm, without the need for secondary polishing, directly improving construction efficiency.

2.Efficient automation, doubling production capacity and saving labor

Realize fully automatic feeding, leveling, forming, cutting, and discharging integrated operations, with flexible adjustment of production speed (8-15m/min). The daily output of a single equipment (8-hour working system) can reach 3000-4500 square meters, which is more than 10 times more efficient than traditional manual processing and can easily meet the urgent needs of large-scale projects. The operational threshold is extremely low, requiring only one staff member to complete parameter settings (length, quantity, speed) through the touch screen, without the need for professional skill training, saving 3-5 labor costs per year. Equipped with an automatic feeding correction device to avoid forming failures caused by coil deviation. The body is made of 16mm thick Q235 steel plate welded as a whole, which is annealed to eliminate internal stress. The structure is stable and anti vibration, and can support 24-hour continuous high-intensity work with stable and uninterrupted production capacity.

3.Durable and energy-saving, long-term operation is more economical

The transmission system adopts a national standard hard tooth surface gearbox and precision roller chain, which runs smoothly without noise and has an annual failure rate of less than 0.5%; The key parts are equipped with overload protection devices, which automatically shut down when the load exceeds the rated value, effectively protecting the motor and mold, and extending the overall service life of the equipment. Equipped with a 7.5-15kw energy-saving motor (adapted according to the model), it reduces power consumption by 30% compared to traditional equipment. Calculated based on an average daily working time of 8 hours, it can save over 10000 yuan in electricity bills annually. The standby mode automatically enters energy-saving mode, further reducing operating costs. The key parts of the fuselage are reserved with maintenance windows, and lubrication points are centrally arranged. Daily maintenance only requires regular addition of lubricating oil and cleaning of mold impurities. Vulnerable parts (cutters, bearings) have strong universality and are easy to replace without the need for special tools, making maintenance convenient and worry free.