Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.15- 0.5mm Width:914mm/1450mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

5T/10T/15T

|

||

|

3.Main body

|

Roller station

|

20 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Gear box transmission

|

|||

|

Dimension(L*W*H)

|

10500*1650*1400 mm(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30-40 m/min

|

The speed is adjustable

|

||

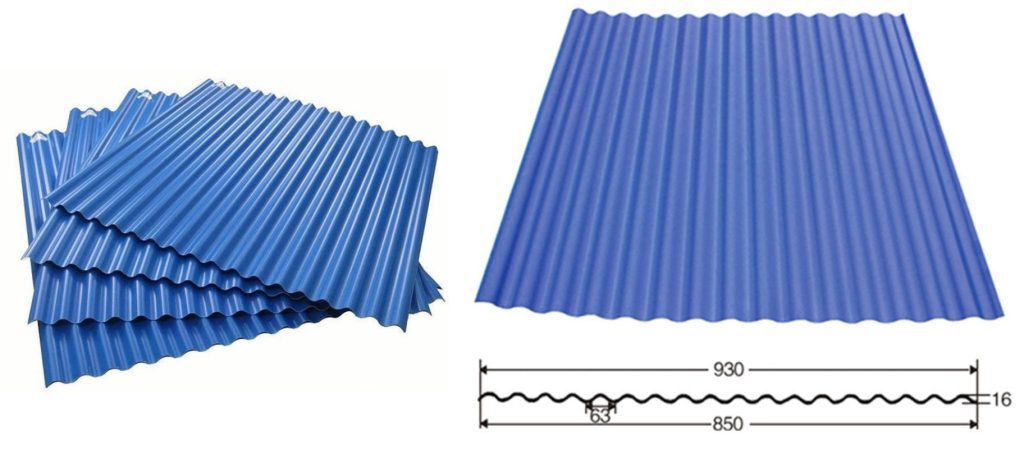

Product Description:

In the field of contemporary architecture, corrugated roofs, as a core element of Eastern architectural aesthetics, are undergoing an industrial upgrade from handmade to mechanically formed. The corrugated roof sheet roll forming machine achieves efficient and precise production of traditional irregular tile parts such as tube tiles and plate tiles through digital control system and modular mold design, allowing the classical eaves curve of “bird like leather, bird like flying” to be reproduced on a large scale. The corrugated roof sheet roll forming machine is a cold bending and pressing equipment specifically used for producing arc-shaped roof tiles, mainly used for decoration and protection of building roofs and walls. This device uses precise molding technology to process metal sheets into tiles with specific curvature, which can meet different architectural styles and design requirements. Adopting industrial computer PLC control to achieve automation of the production process, with simple operation and convenient maintenance. Adopting industrial computer PLC control to achieve automation of the production process, with simple operation and convenient maintenance.

Application areas:

1. Industrial buildings

The tiles produced by the corrugated roof sheet roll forming machine are widely used in the roofs and walls of industrial plants, warehouses, locomotive depots, aircraft hangars and other buildings. These tiles have the characteristics of high strength, corrosion resistance, waterproofing, etc., which can effectively protect the building structure and enhance the aesthetics of the building.

2. Civil buildings

In civil buildings, the tiles produced from corrugated roof tiles are commonly used for the roofs of residential buildings, villas, schools, hospitals, and other buildings. These tiles not only have good waterproof and thermal insulation properties, but also provide rich colors and decorative effects to meet the needs of different architectural styles.

3. Public buildings

The tiles produced by corrugated roof tiles are also widely used in the roofs of public buildings such as sports halls, exhibition halls, cinemas, etc. These buildings usually have high requirements for aesthetics and durability, and the tiles produced by glazed tile machines can well meet these needs.

Advantages of the machine:

1. Meet the design requirements of complex building roofs

(1)Suitable for curved roofs:

The corrugated roof sheet roll forming machine can produce tiles that meet the requirements of building roof curvature, especially suitable for complex roof systems such as circular, semi-circular, and curved shapes. For example, the roofs of modern buildings such as large sports arenas, exhibition halls, and airport terminals often require curved tiles to achieve design effects.

(2)Enhancing the aesthetic appeal of buildings:

By producing tiles with specific curvatures, the corrugated roof sheet roll forming machine can add a unique visual effect to the building, harmonizing the roof with the overall style of the building and enhancing its aesthetic and artistic value.

2. Improve production efficiency and quality

(1)Automated production:

Corrugated roof tile machines typically use automated control systems, such as PLC computer control systems, to achieve full process automation from raw material input to finished product output. This not only improves production efficiency, but also reduces errors caused by manual operations.

(2)High precision molding:

The equipment uses precise roll forming technology to ensure that the size, corrugated, and surface quality of each tile are highly consistent. Compared to traditional handmade production, the quality of tiles produced by machines is more stable and reliable.

(3)Diversified production:

By changing molds or adjusting parameters, the corrugated roof sheet roll forming machine can produce tiles of different curvatures, sizes, and shapes to meet diverse market demands.

3. Enhance roof waterproofing and durability

(1)Waterproof performance:

The tiles produced by the corrugated roof sheet roll forming machine have good waterproof performance, which can effectively prevent rainwater infiltration and protect the building structure from moisture and corrosion.

(2)Durability:

Tiles are usually made of metal materials (such as aluminum alloy, stainless steel, etc.) or high-strength composite materials, which have high strength and corrosion resistance, and long service life.

4. Improve building safety and reliability

(1)Structural stability:

The tiles produced by thecorrugated roof sheet roll forming machine are precisely molded to ensure their strength and stability, and can withstand the influence of natural factors such as wind pressure and snow pressure, ensuring the safety of the building.

(2)Installation reliability:

The corrugated and size of the tiles are precisely controlled to better fit the roof structure, reduce installation errors, and improve installation reliability and sealing.

5. Reduce labor costs and construction difficulty

(1)High degree of automation:

The automated production of corrugated roof sheet roll forming machines reduces reliance on labor and lowers labor costs, especially in areas with high labor costs, where the advantages are more apparent.

(2)Convenient construction:

The size and corrugated of the tiles produced by the machine are consistent, making the installation process more convenient, shortening the construction period, and reducing construction difficulty.