Work flow of machine

https://www.youtube.com/watch?v=5lrdCmyAm10

Introduction of the machine

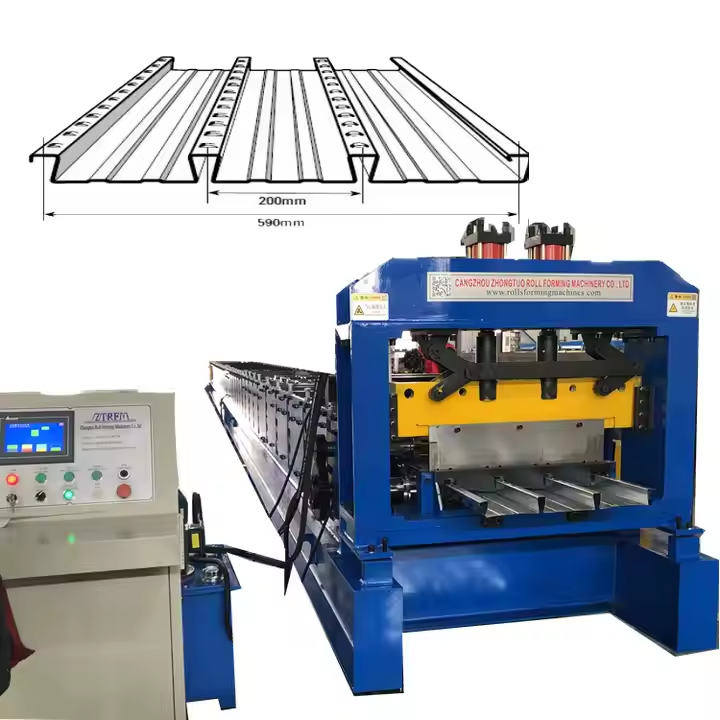

The dovetail floor deck machine is a special mechanical equipment that focuses on the production of dovetail floor decks. With its highly specialized design and manufacturing process, it occupies an important position in the field of architectural metal sheet processing.

As a typical representative of metal corrugated sheets, the dovetail floor deck is widely used in the floor and roof structure systems of various buildings such as industrial plants, commercial complexes, and high-rise residential buildings due to its unique dovetail cross-sectional design and excellent mechanical properties, providing reliable bearing and support functions for building structures. The following will elaborate on the main characteristics and specific work flow of the dovetail floor deck machine:

Main characteristics

Equipment parameters

The dovetail floor deck machine has derived a variety of models and specifications based on different production needs, and each model has obvious differences in technical parameters. Taking the representative JK600 equipment as an example, its overall structural layout is scientific and reasonable, with a total length of 20 meters, a width of 1.6 meters, and a height of 1.3 meters.

This specification design can not only ensure the stability of equipment operation, but also adapt to different production workshop site conditions. In terms of the power system, the equipment is equipped with 3 high-performance motors, each with a power of 11 kilowatts. The powerful power output ensures that the equipment can operate continuously and stably during the production process, and can achieve a production speed of 8-10 meters per minute, effectively meeting the needs of large-scale production.

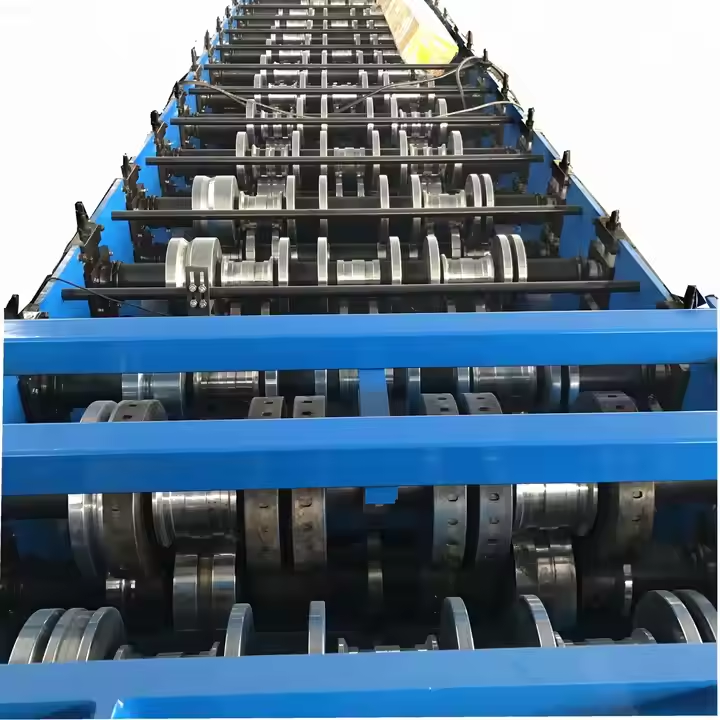

On the core forming components, the equipment is equipped with 36 press shafts, which are matched with press wheels made of bearing steel forgings. This material has the advantages of high hardness, strong wear resistance, and long service life. It can maintain a good working state in high-intensity production operations and ensure press accuracy and product quality.

Electrical control system

The dovetail floor deck machine uses an advanced programmable logic controller (PLC) as the core control unit to build a highly intelligent electronic control system.

The system realizes full automation control of the production process. Operators can easily set key production parameters such as batch quantity, workpiece length, and production quantity through the human-computer interaction interface.

The PLC system has powerful data processing and logical operation capabilities, and can accurately control the operating rhythm and action sequence of each component of the equipment to ensure the efficiency and stability of the production process.

At the same time, the electronic control system also has fault diagnosis and alarm functions. Once the equipment has an abnormal condition, the system can quickly locate the fault point and issue an alarm, which is convenient for maintenance personnel to check and solve the problem in time, effectively reducing equipment downtime and improving production efficiency.

Parameter of Floor Deck Roll Forming Machine

|

Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

Main body

|

Roller station

|

33 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

What is Dovetail Deck?

Dovetail floor decking, also known as dovetail profiled steel sheets, is a widely applied floor decking type in modern construction. As a transitional version evolved from traditional floor decking, it achieves significant breakthroughs in structural design and mechanical properties, becoming a preferred solution for high-rise buildings, large commercial complexes, and other key projects.

In terms of structural mechanics, the dovetail decking features a unique dovetail-shaped cross-section design, enabling efficient composite action with concrete. This design minimizes the section weakening caused by concrete pouring, thereby enhancing the overall load-bearing capacity of the floor slab.

The dovetail structure also provides excellent fire resistance and corrosion protection by reducing direct exposure of steel to environmental erosion. Compared with open-type floor decking, the dovetail system demonstrates notably higher floor stiffness, effectively resisting dynamic loads and deformations during the building’s service life.

In practical engineering applications, the dovetail-type floor decking system offers remarkable utility. It not only serves as a permanent form work providing reliable support for concrete placement during construction but also acts as part of the tensile reinforcement for the floor slab, reducing steel consumption and simplifying construction procedures to cut costs and shorten the construction period.

Under the same slab thickness and load conditions, the dovetail composite floor decking can achieve a larger span due to its optimized mechanical properties, reducing the need for supporting structures and providing greater flexibility for architectural space planning.

Whether ensuring construction safety, improving construction efficiency, or maintaining long-term structural stability, the dovetail-type floor decking has proven its irreplaceable advantages as a key component in modern construction technology.

Application of dovetail deck

The forming part of the dovetail floor deck machine is the core component of the equipment, which is mainly composed of a sturdy and durable frame, efficient and stable transmission components, and a precisely designed cold-bending forming roller set. It adopts Seiko wheel rotation forming technology, which uses the synergistic effect of multiple sets of rollers to gradually form the metal sheet into the required dovetail shape during the progressive cold bending deformation process.

This forming method has multiple advantages: on the one hand, it can ensure the forming accuracy of the dovetail floor deck, so that the dimensional error of the product is controlled within a very small range, meeting the high-standard construction requirements; on the other hand, it effectively reduces the friction between the roller and the raw material, reduces the risk of scratches on the surface of the sheet, and ensures the appearance quality of the product.

In addition, the precision wheel rotational molding structure is reasonably designed, and the debugging process is simple and convenient. Operators can quickly adjust the position and parameters of the rollers according to different production needs to achieve production switching of dovetail floor decking of different specifications, greatly improving the versatility and production flexibility of the equipment.

Recommended related machine