Working flow of machine

https://www.youtube.com/watch?v=oJcTk41x9BE

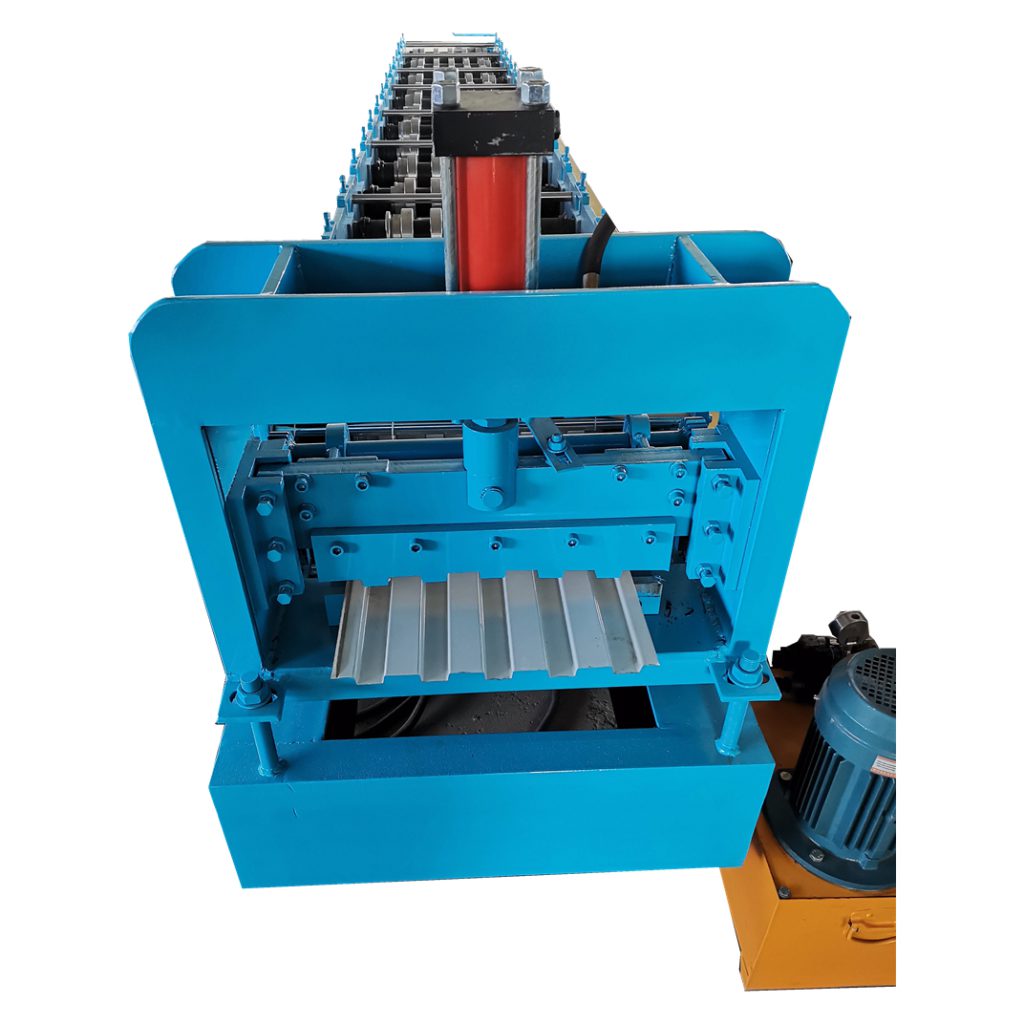

Introduction of shutter door frame machine

A roller shutter door frame machine is used to produce metal roller shutter doors, warehouse doors and other door-type equipment. The equipment includes a full set of devices such as uncoiling, forming, cutting, punching and discharging, which can ensure the fully automatic continuous operation of the equipment. The shearing system adopts servo shearing, which does not stop the machine during punching and shearing, greatly improving the production speed of the equipment.

This advanced equipment realizes the integrated production process from raw material uncoiling to finished product discharging, and the application of servo technology in the shearing link effectively avoids production interruption, making the whole production line more efficient and stable, and fully meeting the needs of large-scale and high-speed production of door products.

Specifications of roll forming machine

| Size | JM85 |

| Dimension | 4000*900*1400mm |

| Weight | 2500KGS |

| Motor Power | 4KW |

| Hydraulic Power | 2.2KW |

| Voltage | 380V/50HZ/3PH |

| Forming Steps | 14steps |

| Forming Speed | 8-12m/min |

| Effective Width | 85mm |

| Material of Width | 136mm |

| Material Thickness | 0.8-1.0mm |

| Tolerance | ±2mm |

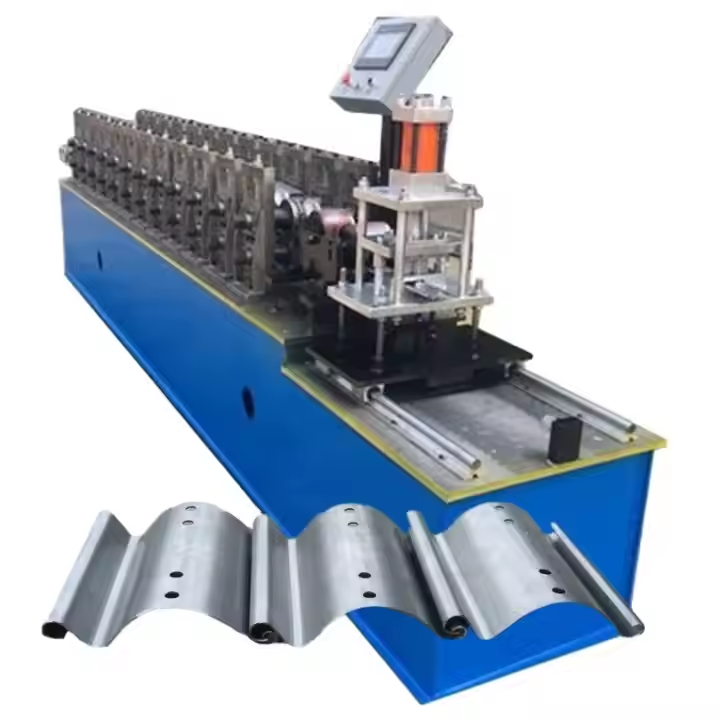

What makes our roll forming machine for shutter doors stand out from the competition?

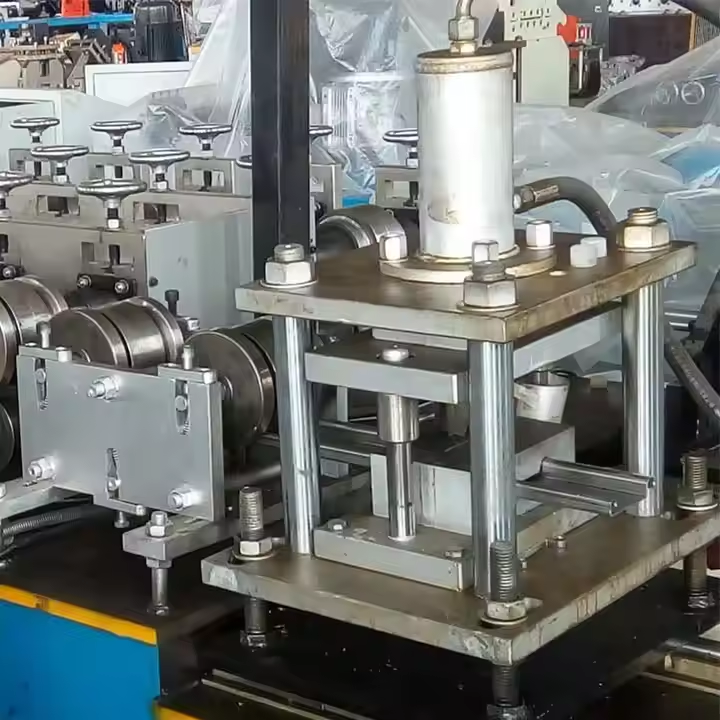

1. In order to produce rolling shutter door panels with perfect shapes, our roll forming machine for shutter doors is equipped with a hydraulic cutting system. This system enables precise and clean cuts, ensuring that each panel meets the strictest quality and dimensional accuracy standards.

2. We have incorporated an expanded set of embossing rollers into our machine. This enhanced roller configuration allows for the production of a wide variety of shutter door styles, accommodating diverse aesthetic and functional needs in the market. Whether for decorative or structural enhancement purposes, our machine can create numerous patterns and textures.

3. Regarding high – speed rolling forming, we utilize a gearbox as the transmission mechanism. This setup allows our machine to reach an impressive production speed of up to 50 m/min. By using components from renowned brands like Siemens, we ensure a stable power output. These top – quality components not only contribute to the machine’s consistent operation but also make replacements straightforward, minimizing downtime and reducing maintenance expenses.

4. The rollers of our roll forming machine are crafted from high – quality materials, guaranteeing durability and long – term performance. Our roller quality is supported by comprehensive laboratory – tested data, which verifies their excellent mechanical properties, wear resistance, and overall functionality.

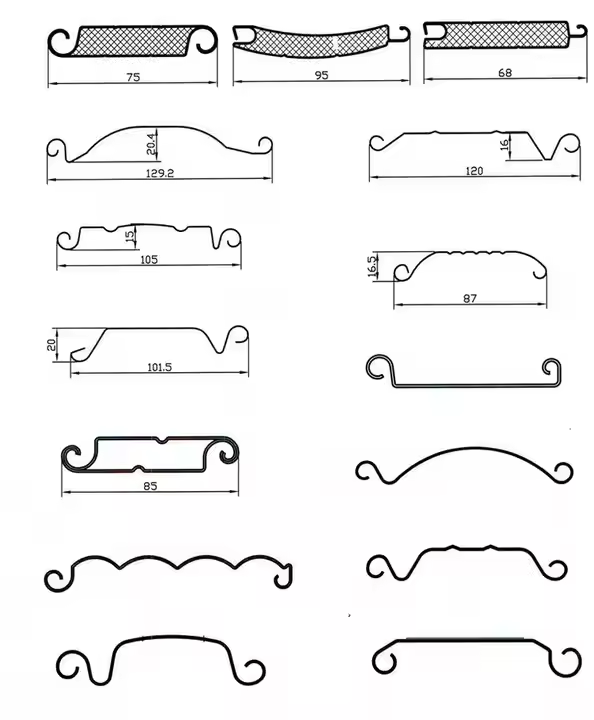

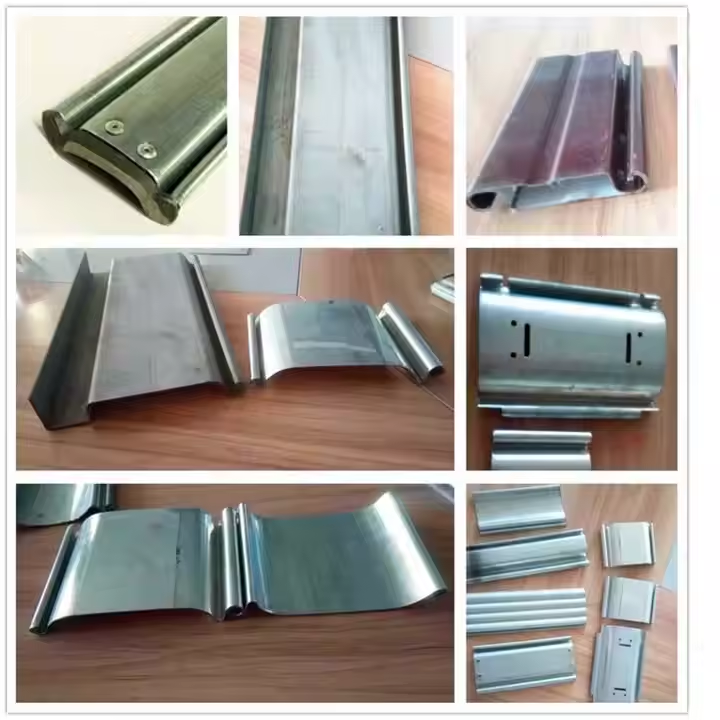

Some finished rolling door products and profile drawings are shown

Recommended related machine