Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

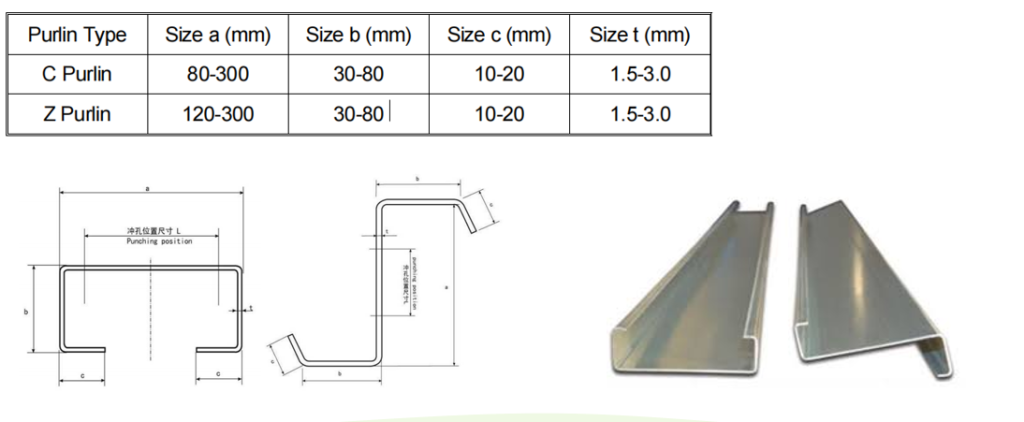

Product Description:

In the field of modern architecture and machinery manufacturing, CZ steel machines are redefining steel structure production efficiency with their revolutionary design concepts. This intelligent device, which integrates the production functions of C-shaped steel and Z-shaped steel, has solved the pain points of traditional production lines through technological innovation and become a model of flexible manufacturing in the Industry 4.0 era.

1.Technological Innovation: A Leap from Separation to Integration

Traditional steel production lines require separate configuration of C-shaped steel machines and Z-shaped steel machines, while CZ steel machines achieve functional integration through three core breakthroughs:

- Infinite switching system:

Using PLC intelligent control technology, the operator only needs to input the target specification parameters (such as web height and flange width) on the touch screen, and the equipment can automatically adjust the relative position of the 18 component roller, completing the C/Z type switch in as fast as 3 minutes. Its unique “coaxial transmission+modular roller set” design ensures even force distribution on both sides during the molding process, avoiding the common single-sided distortion defects of traditional equipment - Adaptive cutting technology:

Equipped with a hydraulic servo fixed length cutting system, the length is calibrated in real-time through laser ranging, with an accuracy of ± 0.5mm. What’s even more groundbreaking is its “universal cutting blade holder”, which can automatically adjust the cutting angle according to the cross-sectional shape of the profile, completely eliminating the problem of frequent tool changes and downtime. According to actual test data from a steel structure enterprise, this technology reduces the changeover time by 87% and increases production capacity by 3.2 times.

2. Industrial application: Supporting the steel structure of modern architecture

- In practical applications, CZ steel mills have demonstrated significant advantages:

In the field of architecture, a single device can meet the needs of different scenarios such as factory purlins and solar brackets. In a modular building project in Xiong’an, the roof support system was reduced by 15% while maintaining load-bearing standards by switching C/Z specifications in real-time.

- Rail transit:

When used for the production of carriage frames, its thickness adjustment range of 1.5-3mm can accurately match different strength requirements, and the molding speed can reach 20 meters/minute, which is 40% more efficient than traditional processes.

Specific application examples:

1.In the field of architecture:

C-shaped steel and Z-shaped steel are respectively used for the manufacturing of components such as purlins, wall beams, roof trusses, and brackets in steel structure buildings.2.Mechanical manufacturing:

C-shaped steel and Z-shaped steel are also used for mechanical equipment frames, conveying equipment, carriage frames, and chassis structures.3.Transportation:

Z-shaped steel is widely used in the carriage frame and chassis structure of trucks, trailers, and other vehicles.4.Warehouse logistics:

Both C-shaped steel and Z-shaped steel are used in the beams and columns of warehouse shelves.Products Display: