In the wave of continuous innovation in the modern construction industry, light steel villas have gradually become a new trend in residential construction with their advantages of environmental protection, efficiency, and earthquake resistance. As a key equipment for the production of light steel villa frames, villa keel equipment is the core force driving the development of this trend. It has laid a solid foundation for the stability and safety of light steel villas with exquisite craftsmanship and intelligent design, becoming an indispensable and important equipment in the field of construction.

Applicable Scenarios:

With excellent performance, villa keel equipment has a wide range of applications in the field of light steel villa construction, whether it is different styles of villa types or different building parts of villas, its presence can be seen.

From the perspective of villa style, whether it is a simple and fashionable modern style light steel villa, a natural North American style single story villa, or an elegant and atmospheric European classical style multi story villa, the villa keel equipment can produce matching keel components according to design requirements. For example, in North American style single story villas, equipment can produce lightweight wall and roof studs to meet the villa’s needs for transparency and comfort in living; In European classical style multi story villas, equipment can produce high-strength load-bearing keels to ensure the stability and safety of the building.

From the perspective of building components, the keel produced by villa keel equipment can be widely used in key areas such as walls, roofs, and floors of light steel villas. In wall construction, the keel serves as the supporting skeleton for the wall, used to fix gypsum board, insulation materials, etc., forming a composite wall with sound insulation, thermal insulation, and fire prevention functions; In roof construction, the roof truss composed of keel can effectively bear the weight of roof tiles, waterproof layers and other materials, and resist the influence of external environment such as wind and rain; In floor construction, the keel plays a role in supporting the floor surface layer and adjusting the flatness of the ground, providing residents with a comfortable walking experience.

In addition, villa keel equipment is also suitable for various derivative projects related to light steel villas, such as the addition and renovation of light steel villas, as well as characteristic building projects such as light steel homestays and light steel vacation homes. In these projects, the equipment can flexibly adjust the specifications and styles of the keel according to the special needs of the project, providing customized keel solutions for the smooth implementation of the project, and promoting the application and development of light steel buildings in more fields.

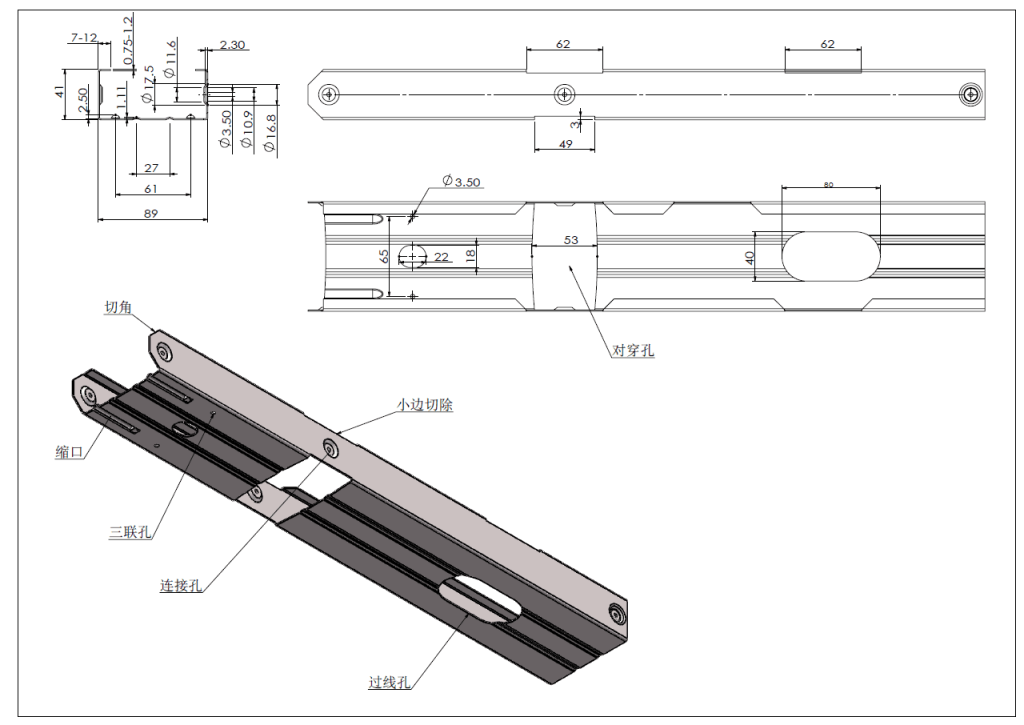

Pattern drawing:

Machine section introduction:

|

Part 1. Manual decoiler

|

||||

|

ID

|

450 – 550mm

|

|||

|

Coil Width

|

300 mm

|

|||

|

Coil load

|

3 ton

|

|||

|

Part 2. Punchin device

|

||||

|

Punchine die material

|

SKD11

|

|||

|

Punching 6 sets

|

50X12mm side hole

|

|||

|

Beehive holes

|

||||

|

Function bolt for easy installation

|

||||

|

60x30mm for cable tray holes

|

||||

|

89×50 for the square holes

|

||||

|

web hole and 45 degree bending or shearing.

|

||||

|

Note

|

if your country bolt sizes are different, please tell me in advance.

|

|||

|

Part 3. Main rolling forming machine

|

||||

|

Transmission

|

we use gear, chain as tranmission.

|

|||

|

Main servo motor

|

5.5kw

|

|||

|

Roller material

|

SKD11

|

|||

|

Shaft mateiral

|

40Cr

|

|||

|

Forming speed

|

30m/min

|

|||

|

Production capacity

|

0 to 100 square meter per day, if you work 8 hours per day.

|

|||

|

part 4. Hydraulic Shearing System

|

||||

|

Power

|

5.5kw

|

|||

|

Oil tank

|

120OL

|

|||

|

Brand

|

Yuken series

|

|||