https://www.youtube.com/watch?v=n5A-kW_VxO0

Full Automatic Light Gauge Steel Frame Roll Forming Machine for House Villa

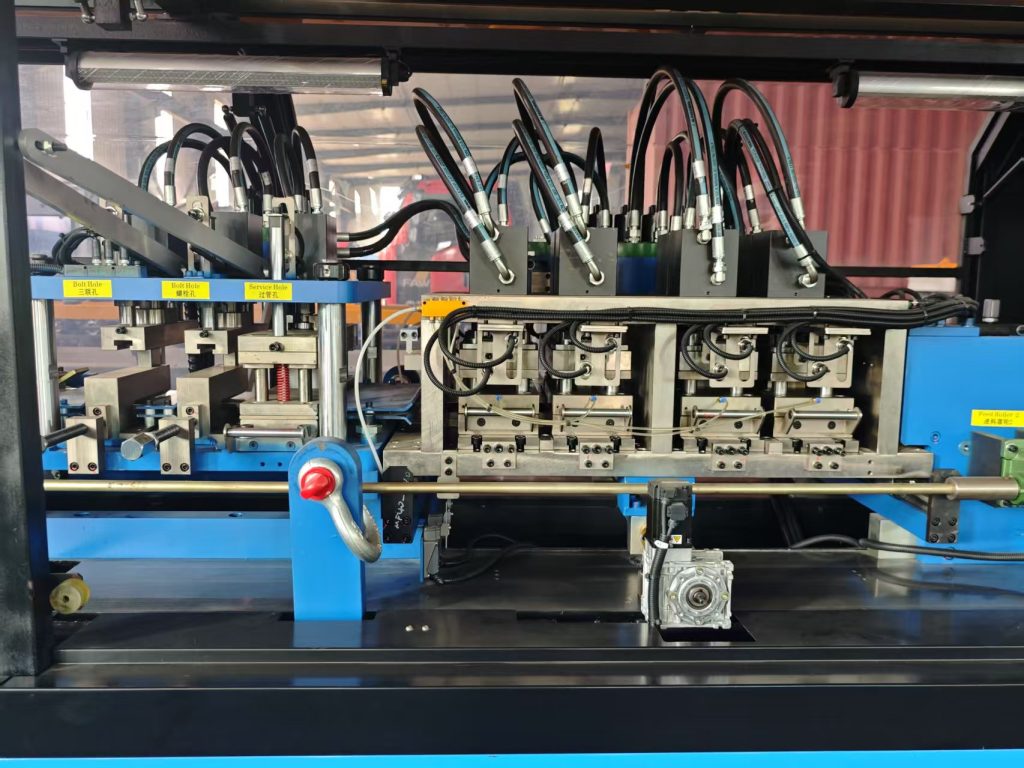

Light gauge steel frame roll forming machine is suitable for high-strengthcold roll former light-steel structure building forming machinery and equipmentsystem is a forming equipment system designed for specific building manufacturing enterpriseAnd this machine integrate of component production and manufacturing,achieving high automation, efficiency, high quality, and high speed.Components Of this Machine:

-The seryo motor

-Hydraulic system

-Colding system

-Digital control system

The Light Gauge Steel roll forming machine enables the intelligentization of architectural designproduction

and processing, construction, and installation by integrating a full version of thedesign softwareand seamlessly linking the equipment system and the software.Suitable for building:

Express lodgings, car clubs and hotels, civil dwellings, low-cost housing, andagriculture,

rehabilitation of housing in pastoral and forestry areas and housing for employees’dormitories,

making cold-formed thin-walled commercial and industrial buildings, trusses,mobile homes,

modular homes, and other structures buildings with steel frames, etc.

The fully automatic intelligent Light Gauge Steel making machine has independent intellectualproperty rights, highly intelligent production control software,and can carry out production tasks simply and quickly.It can generate 300-700 meters of light steel construction profiles per hour atthe top industry pace.

The light gauge steel profile produced by the 89 type light steel gauge keelmachine has the characteristics of the industry and can be installed quickly andquickly.

The VERTEX light steel profile design software integrated with the standard 89type light steel keel equipment production system conforms to the developedbuilding codes of Australia and New Zealand and the cold-formed thin-walllight steel (LGS) structure design standards.

Main parameters of the machine

|

1.Formed Material |

PPGI,GI,AI |

Thickness:0.7-1.2mm |

||

|

2.Decoiler |

Hydraulic automatic decoiler |

Manual decoiler(will give you as free) |

||

|

3.Main body |

Roller station |

12 rows(As your requirement) |

||

|

Diameter of shaft |

50mm solid shaft |

|||

|

Material of rollers |

45# steel, hard chrome plated on the surface |

|||

|

Machine body frame |

Metal steel welded |

|||

|

Drive |

gearbox transmission |

|||

|

Dimension(L*W*H) |

5500*800*1200(customize) |

|||

|

Weight |

About 3T |

|||

|

4.Cutter |

Automatic |

cr12mov material, no scratches, no deformation |

||

|

5.Power |

Motor Power |

7.5KW |

||

|

Hydraulic system power |

5.5KW |

|||

|

6.Voltage |

380V 50Hz 3Phase |

As your requirement |

||

|

7.Control system |

Electric Box |

Customized(famous brand) |

||

|

Language |

English(Support multiple languages) |

|||

|

PLC |

Automatic production of the whole machine. Can set batch, length, quantity, etc. |

|||

|

18.Forming Speed |

60-70m/min(customized) |

The speed depends on the shape of the tile and the thickness of the material. |

||

Finished product application display

Recommend related machine