In the vast world of the metal processing industry, metal embossing machines are quietly playing an indispensable key role. It is like a magical artist, endowing cold and monotonous metal plates with new life and charm, transforming them into exquisite works of art or products that combine practicality and aesthetics.

Working principle: Integration of precision machinery and art:

The working principle of metal embossing machine is based on the exquisite science of physical deformation. Taking the ZTRFM metal embossing machine as an example, its core operating mechanism is to precisely apply mechanical force to the metal material to induce plastic deformation on the metal surface. High quality molds made of hard alloys or other durable materials play a crucial role in this process. These molds are like carefully carved seals. When the metal sheet is driven by the machine and slowly passes between the upper and lower molds, the concave and convex textures of the molds will be clearly engraved on the metal surface under precise pressure control, transforming the originally ordinary metal sheet into unique products decorated with complex patterns and exquisite textures. This precise control of pressure and mold movement ensures that every embossing detail can be perfectly presented, whether it is delicate lines or three-dimensional patterns, they are clear and distinguishable, fully demonstrating the precision craftsmanship of the metal embossing machine.

Excellent features: a perfect combination of efficiency, diversity, and quality:

1.Efficient production, improving production capacity

Modern metal embossing machines are equipped with advanced automation systems and efficient power devices, greatly improving production efficiency. Many devices use PLC (Programmable Logic Controller) and touch screen operation interface. Operators only need to easily input relevant parameters on the screen, such as embossing pattern, depth, board thickness, etc., and the machine can quickly respond and automatically complete the entire embossing process. Compared to traditional manual embossing methods, its output can increase several times or even tens of times. For example, some large metal embossing production lines can process a large amount of metal coils per hour, continuously outputting high-quality embossed products, greatly meeting the needs of large-scale production and winning time advantages for enterprises in fierce market competition.

2. Diverse functions to meet diverse needs

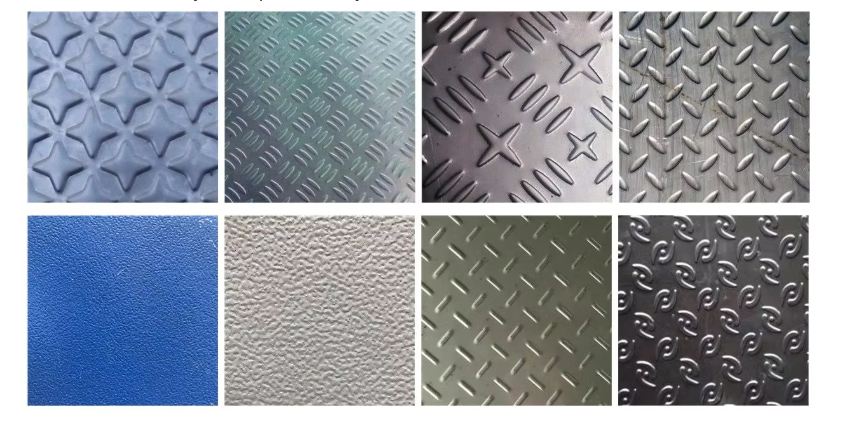

One significant advantage of metal embossing machines is their powerful versatility. It can adapt to the processing of various metal materials, including aluminum foil, color coated steel plate, hot-dip galvanized plate, copper plate, cold-rolled plate, stainless steel plate, etc. Whether it’s soft aluminum foil or high hardness stainless steel plates, metal embossing machines can easily handle them, adjusting parameters according to the characteristics of different materials to achieve ideal embossing effects. At the same time, the machine can press a wide variety of patterns, including common patterns such as willow leaf pattern, three leaf pattern, phoenix eye pattern, lucky flower, leopard flower, diamond pattern, orange peel pattern, rice grain pattern, etc., and can customize personalized pattern molds according to customers’ special needs. This enables metal embossing machines to be widely applied in different industries and fields, meeting diverse design needs.

3. High quality products ensure quality

Quality is the lifeline of a product, and metal embossing machines perform excellently in ensuring product quality. On the one hand, high-quality molds and precise mechanical structures ensure the stability and accuracy of the embossing process, effectively reducing the rate of defective products. The pressed patterns are full, smooth, three-dimensional, clear, uniform, and beautiful, greatly improving the appearance quality of metal products. On the other hand, through embossing treatment, the metal sheet has increased its strength and rigidity to a certain extent, improving the durability and practicality of the product. For example, embossed metal sheets used in the construction industry not only add unique decorative effects to buildings, but also exhibit better performance when subjected to external forces, extending the service life of buildings.

Widely used: shining stars in multiple fields:

1. In the field of architectural decoration

In the field of architectural decoration, metal embossing machines are widely used. From decorative panels on exterior walls of buildings, to decorative lines on ceilings and walls indoors, and even to anti slip treads in stairwells, metal embossed products are ubiquitous. Embossed metal sheets bring a unique artistic atmosphere and modernity to architecture with their rich patterns, diverse colors, and excellent durability. For example, some high-end office buildings and hotels use embossed aluminum panels with metallic texture and exquisite patterns as exterior wall decoration, which not only makes the building appearance more beautiful and atmospheric, but also effectively resists wind and rain erosion, improving the overall quality of the building. Meanwhile, in indoor decoration, decorative pieces made of embossed copper or stainless steel plates, such as lamp covers, door handles, etc., add a delicate and luxurious atmosphere to the space.

2. Vehicle manufacturing industry

The vehicle manufacturing industry is also one of the important application areas of metal embossing machines. In the manufacturing process of transportation vehicles such as cars, trains, and ships, metal embossed products are widely used in the bottom plate, interior panel, doors, and other parts of the carriage. The embossed metal sheet not only provides better anti slip performance, ensuring the safety of passengers and operators, but also increases the strength of the sheet and improves the overall structural stability of the vehicle. For example, using embossed steel plates on the bottom of truck compartments can effectively prevent goods from sliding and reduce safety hazards during transportation; In the interior of automobiles, the use of metal decorative panels with exquisite patterns can enhance the luxury and comfort of the car, meeting consumers’ pursuit of quality and aesthetics.

3.Furniture and hardware industry

In the field of furniture and hardware, metal embossing machines also play an important role. Furniture accessories made of various metal materials, such as handles, hinges, decorative strips, etc., after embossing treatment, not only have a more beautiful and exquisite appearance, but also enhance the added value of the product. Embossing technology can endow furniture hardware products with unique textures and textures, making them complement different styles of furniture. For example, in retro style furniture, using embossed metal handles with classical patterns can create a strong retro atmosphere; In modern minimalist furniture, simple and smooth embossed lines can add a sense of fashion and refinement to the furniture.

4. Other fields

In addition to the aforementioned industries, metal embossing machines are also widely used in many fields such as mechanical manufacturing, electronic appliances, and packaging. In mechanical manufacturing, embossed metal sheets can be used to make protective covers, control panels, and other components, providing both protection and decorative value; In the field of electronic appliances, metal embossed products can be applied to computer cases, mobile phone cases, etc., to enhance the appearance quality and brand image of products; In the packaging industry, embossed metal foil can be used to make high-end gift packaging, food packaging, etc., increasing the beauty and attractiveness of the packaging.