The fully automatic CZ steel machine is a specialized equipment that uses cold bending forming technology and is controlled by a numerical control system to achieve automated processing of metal sheets from feeding, leveling, punching, forming to cutting. It can flexibly switch between producing C-shaped steel and Z-shaped steel. The C-shaped steel and Z-shaped steel processed by it are widely used in various steel structure projects due to their reasonable cross-sectional shape, excellent load-bearing performance, and convenient installation.

The core advantage of this device lies in the combination of “fully automatic” and “dual models”. Fully automatic “is reflected in the entire processing flow from raw material loading to finished product output, without excessive manual intervention, and can be completed through preset programs; ‘Dual model’ means that there is no need to replace the entire equipment. By adjusting the unit parameters and molds, it is possible to quickly switch between the production of C-shaped steel and Z-shaped steel profiles with different cross-sections, greatly improving the universality and production flexibility of the equipment and reducing the equipment investment cost of the enterprise.

From the perspective of processing materials, the fully automatic CZ steel machine can adapt to various metal plates such as cold-rolled steel plates, galvanized steel plates, and color steel plates with thicknesses ranging from 1.5mm to 6.0mm. It can process high-quality products that meet the standards according to the needs of different industries for steel materials. At the same time, the equipment is equipped with an advanced CNC operating system, and operators can intuitively set processing parameters such as the length, aperture, and spacing of profiles through the touch screen. The system will automatically memorize the parameters, making it convenient for subsequent mass production of similar products.

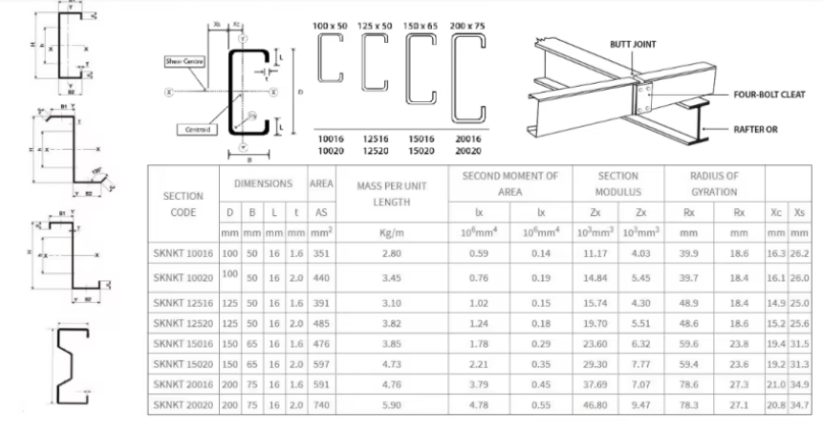

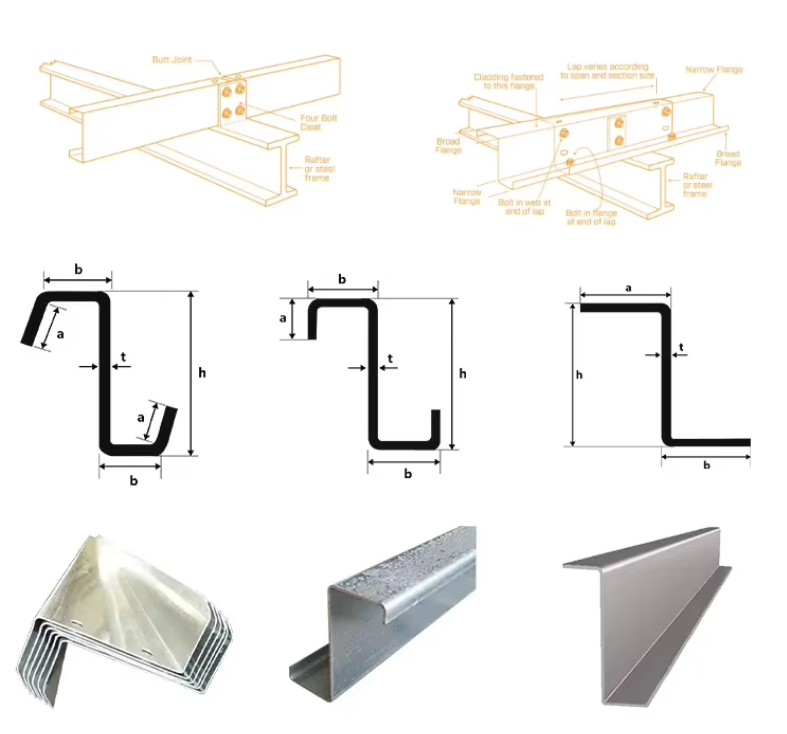

Pattern drawing:

Performance characteristics:

1. Efficient production and cost reduction

The fully automatic CZ steel machine realizes the full process automation from raw material processing to finished product output, with a production speed of up to 8-15 meters per minute, which is 3-5 times more efficient than traditional manual or semi-automatic equipment. At the same time, the equipment does not require excessive manual operation, reducing labor costs, and the material utilization rate is high during the processing, with less waste, effectively reducing the production cost of the enterprise and enhancing the market competitiveness of the product.

2. Precise processing, stable quality

The equipment adopts high-precision machining components and advanced CNC control system, from leveling, punching to forming and cutting, the accuracy of each process is strictly controlled, ensuring that the size of the processed C-shaped steel and Z-shaped steel is accurate, the cross-sectional shape is regular, and the surface quality is good. In addition, the stable operating performance of the equipment ensures the consistency of product quality during mass production, reduces the defect rate, and provides reliable product quality assurance for enterprises.

3. Flexible switching, strong universality

One of the biggest features of the fully automatic CZ steel machine is its flexible ability to switch between producing C-shaped steel and Z-shaped steel. By adjusting the parameters of the cold bending forming unit and replacing the corresponding punching mold, the machine model can be switched in a short period of time without the need to replace the entire equipment, adapting to the needs of different industries for different cross-sectional steel. At the same time, the equipment can process metal sheets of various thicknesses and materials, further enhancing its versatility and meeting diverse production needs.

4. Stable and reliable, easy to maintain

The core components of the equipment are made of high-quality materials and well-known brand products, and undergo strict quality testing and trial operation to ensure stable and reliable operation with a low failure rate. At the same time, the structural design of the equipment is easy to maintain, and the disassembly and replacement of key components are convenient. The electronic control system provides a complete fault diagnosis function, which facilitates quick troubleshooting and resolution of equipment failures, reduces equipment downtime, and ensures production continuity.

5. Safe and environmentally friendly, in compliance with standards

The fully automatic CZ steel machine is equipped with comprehensive safety protection devices, such as emergency stop buttons, overload protection, safety barriers, etc., to ensure the personal safety of operators. At the same time, the equipment produces no noise, dust or other pollution during the processing, which meets national environmental standards and provides a good working environment for operators, as well as meeting the needs of green production in enterprises.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

24 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 14T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||