Working flow of stud and track roll forming machine

https://www.youtube.com/watch?v=MZEk5dvp5eI

Advantages of Stud and Track Roll Forming Machine

1. High-speed Production: The stud and track roll forming machine achieves a high-speed production of 30 meters per minute, far exceeding similar products in the industry. This significantly shortens the working time of the villa keel machine and reduces labor costs.

2. Continuous Cooling System: To adapt to long-term production, each set of press roller wheels of the villa light steel keel machine is equipped with a circulating cooling system to maintain stable working temperature of the roller group.

3. Integrated Gearbox Transmission: Adopting integrated gearbox transmission, all gears are ground with low noise. The immersion oil lubrication ensures long service life.

4. Precision Machining of Frame: All machining of the frame is completed in one go, ensuring the accuracy of each matching dimension and position of the machine tool. This makes the roll forming unit almost free from repeated debugging and highly independent of personnel.

The stud and track roll forming machine adopts fully automatic computer PLC control system technology, featuring simple and convenient parameter setting, high degree of automation, and self-learning system. All control components use domestic and foreign high-quality machines, ensuring stable operation and a user-friendly human-machine interface.

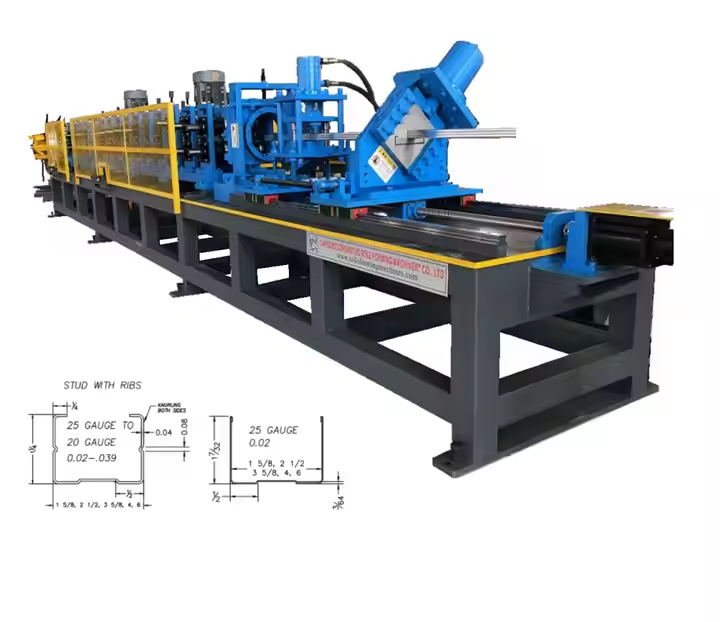

Main roll forming machine

| Roller station | 12 rows(As your requirement) | ||

| Diameter of shaft | 50mm solid shaft | ||

| Material of rollers | 45# steel, hard chrome plated on the surface | ||

| Machine body frame | Metal steel welded | ||

| Drive | gearbox transmission | ||

| Dimension(L*W*H) | 5500*800*1200(customize) | ||

| Weight | About 6T |

Characteristics of Stud and Track Roll Forming Machine

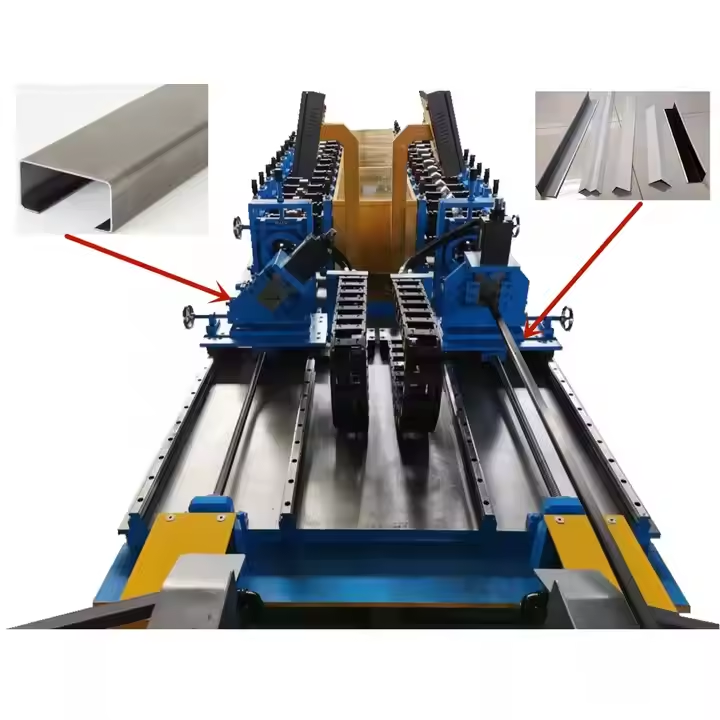

1. Section Dimensions Design: The flange height of the formed studs and tracks exceeds industry standards, featuring a large moment of inertia. This ensures strong structural stability and facilitates convenient construction.

2. Superior Structural Stability: The studs and tracks demonstrate excellent stability in load-bearing and deformation resistance, maintaining consistent performance under various conditions.

3. Cost-efficiency and High Performance: These components are not only easy to install and use but also enhance the combined strength and stability of the structure. Meanwhile, their optimized design reduces material consumption, leading to low comprehensive costs.

4. Standardized Buckle Connection System: The standardized buckle connection keeps the studs and tracks flat, effectively preventing ceiling waviness caused by rusting of small components or deformation of the keels.