High Speed Double Line Light Steel Keel Roll Forming Machine

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

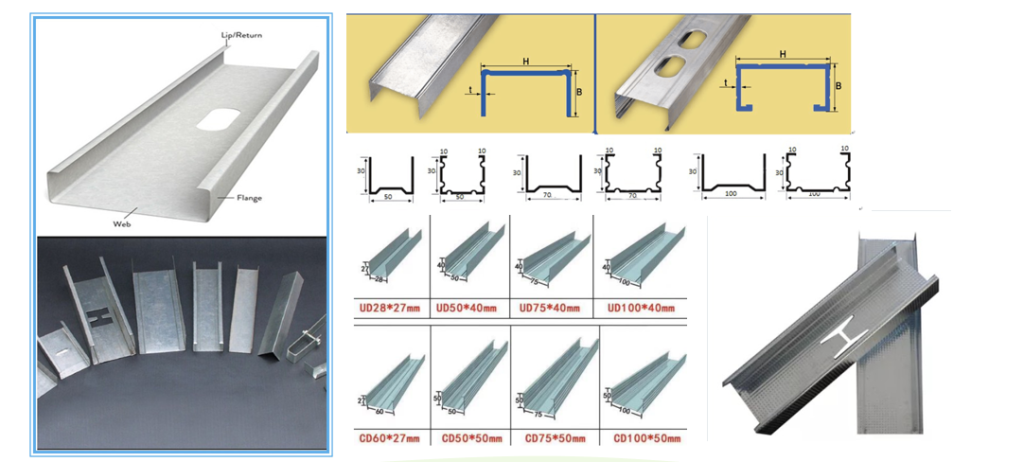

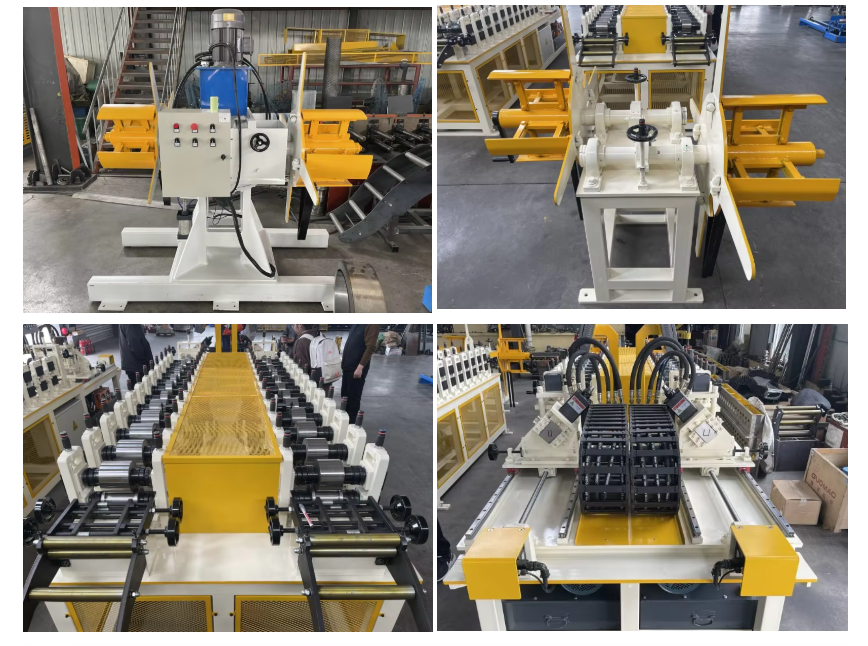

Product Description:

As a key equipment for the production of building profiles, the high speed double line light steel keel roll forming machine can achieve integrated production of various building profiles such as light steel keels and ceiling keels through modular design. It can meet the needs of different scenarios without frequent equipment replacement and maximize equipment utilization. Zhongtuo equipment adopts PLC control system and intelligent control, supporting rapid parameter adjustment and real-time analysis of production data, significantly improving machining accuracy and stability. Compared to the traditional multi machine combination mode, combination design can reduce equipment footprint by about 30% and lower costs by optimizing material utilization.

The produced keel profiles have waterproof, soundproof, seismic and other properties, suitable for scenarios such as integrated ceilings and steel structure houses, while meeting the requirements of modern architecture for lightweight and environmental protection.