How is the Step tile and IBR sheet produced?

Our Step tile and IBR sheet Double deck Roll Forming Machine 0.2-0.8mm is used to produce the Step tile and the IBR sheet,the raw material can be PPGI color steel,galvanized steel and other material as request.One double deck roll forming machine can produce two different products.

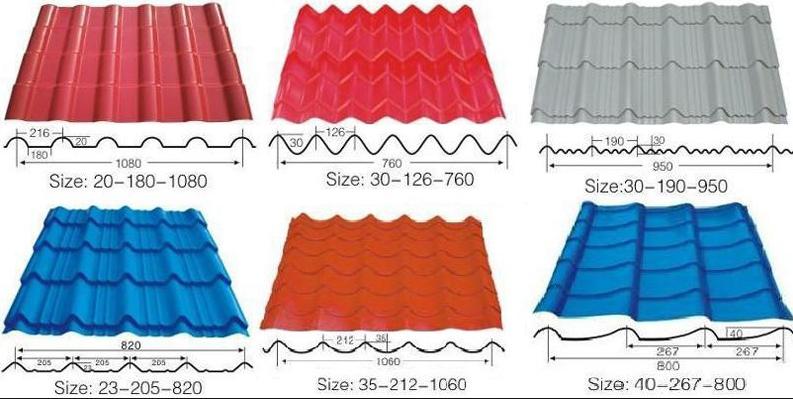

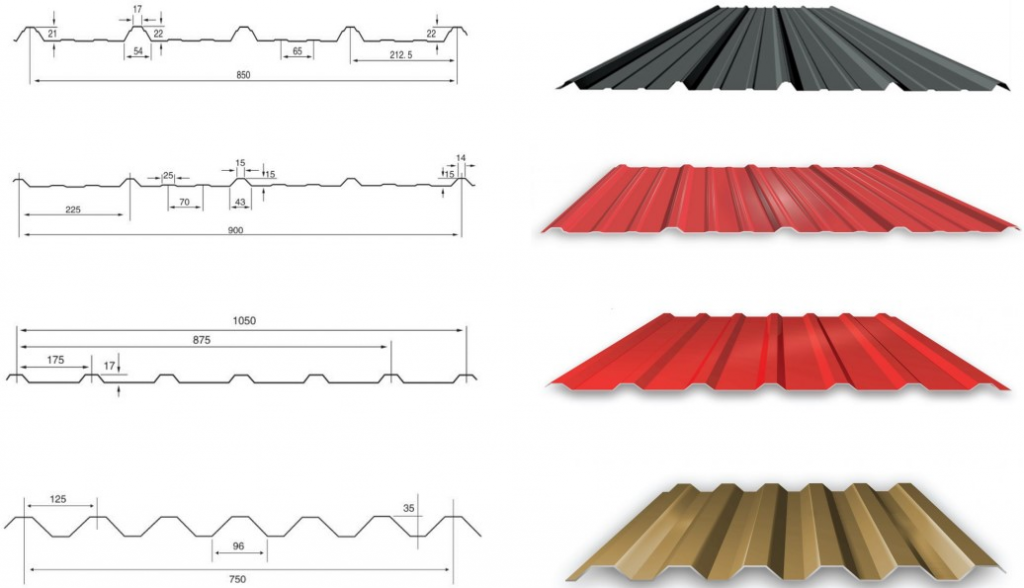

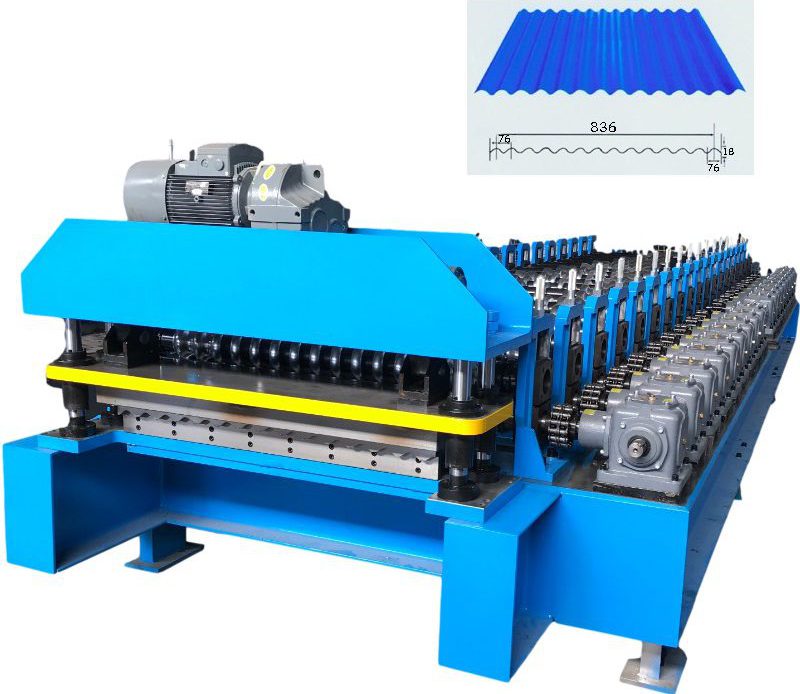

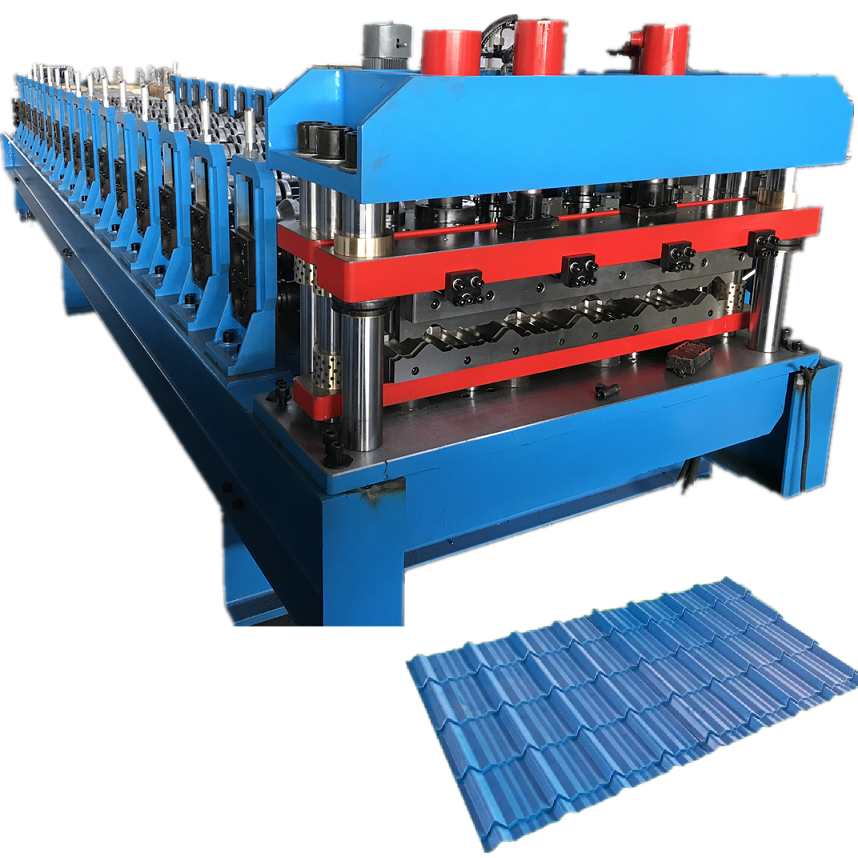

The pictures for the Step tile and IBR sheet(The profile drawing can be produced as customer’s request):

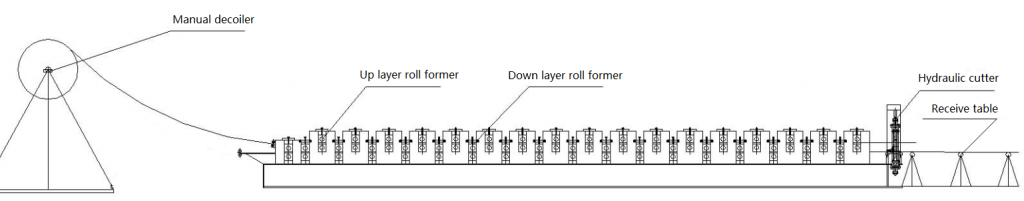

The whole components of the Step tile and IBR sheet Double deck Roll Forming Machine include:Decoiler,roll forming machine,hydraulic cutting system,control system and product table.

The working layout for the whole Step tile and IBR sheet Double deck Roll Forming Machine production line:

The introduction for each part of Step tile and IBR sheet Double deck Roll Forming Machine:

Part 1:Decoiler

Function:It is used to expand the coil for the next roll forming process.

Capacity:5 tons is widely used,but 8ton,10tons are all optional,we can customize as customer’s request

Type:Automatic and manual two kinds of decoiler which is optional for customer.

Machines’ picture for reference:

Part 2: Roll forming machine

Function: To roll form the plain plate to the request sizes of Step tile and IBR sheet.

Main specifications:

- Roller station:13+17 stations

- Roller material:45# steel with quenched treatment

- Shaft material:45# steel with quenched treatment

- Shaft diameter:80mm,full solid

- Power:5.5kw

- Transmission:By double chains

- Main frame:350# H steel

- Middle plate:18mm thickness

Pictures for reference:

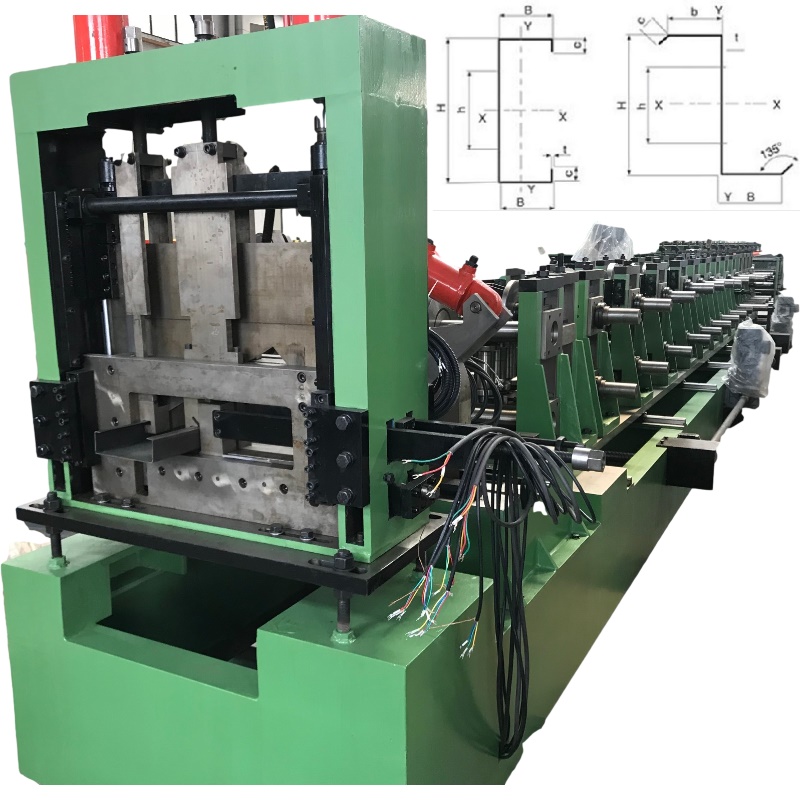

Part 3: Hydraulic cutting system

Function:Used to cut the sheet after roll forming

Main specifications:

- Cutting blade material:Cr12 with quenched treatment

- Hydraulic power:5.5kw

- Cooling system:Fan cooling

Picture for reference:

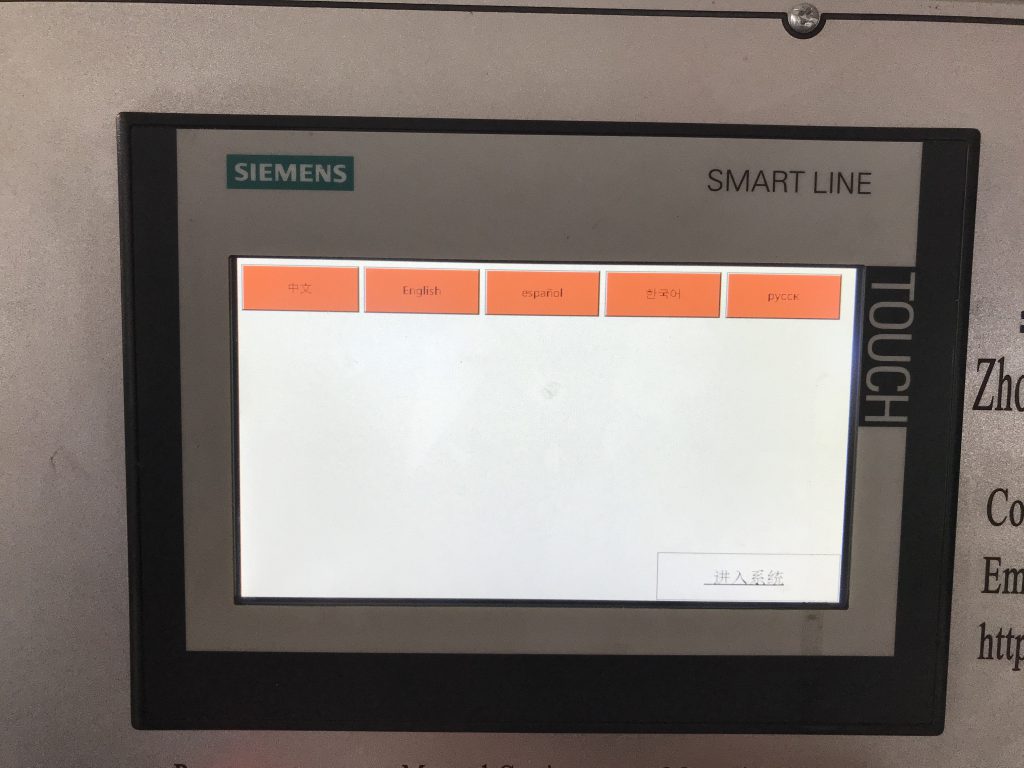

Part 4:Control system

Function:Used to control the working speed,the quantity and batch of the finished product.

Main specifications:

- Control system:PLC

- PLC brand:Delta from Taiwan,or Siemens,Schneider

- Touch screen:Delta from Taiwan,or Siemens,Schneider

- Encoder:Omron brand

- Low pressure apparatues:Schneider

- Language:Chinese/English/Spanish/France/Russian/Arabic

- Aviation plug for easy connection for customers.

Pictures for reference:

Part 5:Product receive table

Function:Used to receive the product after cutting

Working type:Manual or Automatic

Length:3m/set

Quantity:2 sets

Pictures for reference:

Working video for reference:

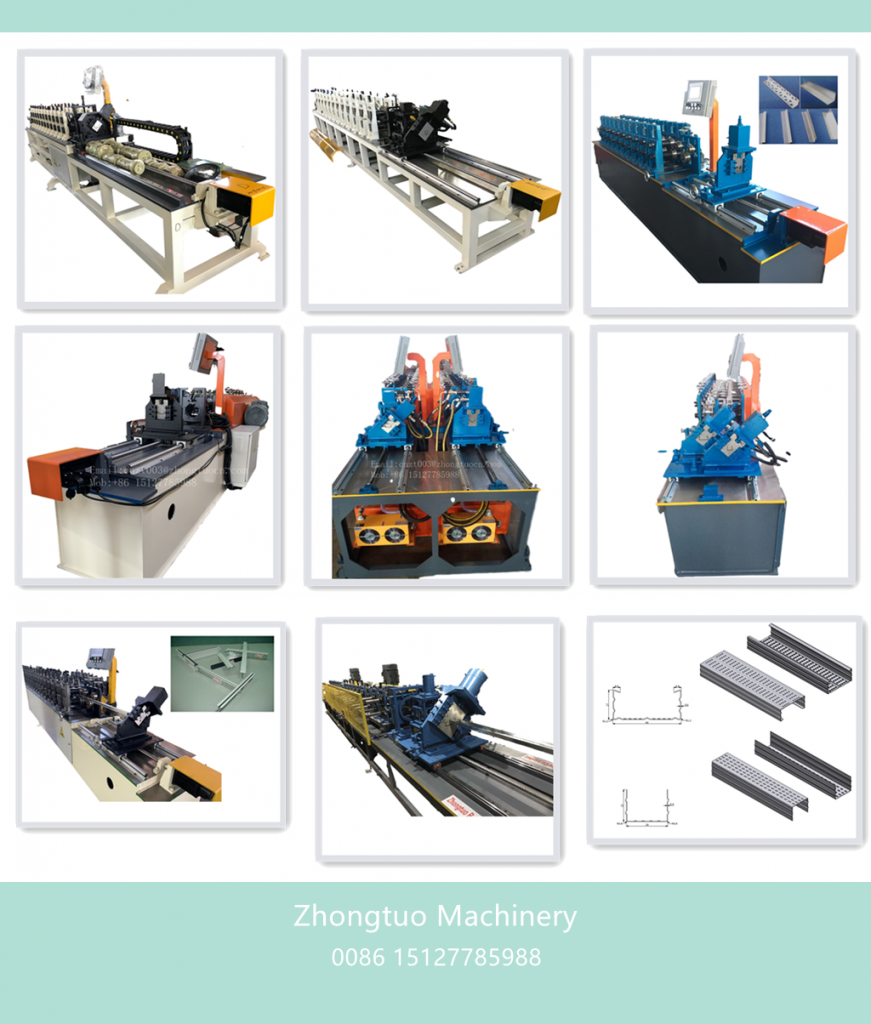

Recommanded related roll forming machines: