Stainless Steel square Welding Pipe Making Machine Laser Welding Pipe Machine is a specialized laser welding equipment developed for square, rectangular pipes, square boxes and other workpieces. Its core principle is to use high-energy density laser pulses to locally heat small areas of the material. The energy radiated by the laser is guided to the interior of the material through thermal conduction, causing the material to melt and form a specific molten pool, ultimately achieving precision welding of the workpiece. Compared with traditional welding equipment, the Stainless Steel square Welding Pipe Making Machine Laser Welding Pipe Machine has achieved breakthrough upgrades in structural design, control system, welding accuracy, and has distinct technical characteristics.

Multi field application of square laser welded pipe machine: empowering high-quality development in various industries

With excellent performance and wide adaptability, square laser welding machines have been deeply applied in various fields such as construction, automotive, furniture, industrial manufacturing, renewable energy, etc., becoming the core equipment for improving product quality and production efficiency in various industries, promoting technological upgrading and industrial transformation in related industries.

• In the field of architecture and infrastructure

In construction and infrastructure, square laser welding machines are mainly used for welding and processing square pipes, such as building structural frames, bridge support components, fencing and rails, scaffolding, etc. Square pipes have the characteristics of high strength, good stability, and beautiful appearance. The welded seams of the pipes after laser welding are smooth and have excellent strength, which can effectively ensure the safety and durability of building structures.

• Automotive manufacturing field

The automotive manufacturing industry has extremely high requirements for precision, strength, and lightweight components. Square laser welding machines precisely meet these core needs and are widely used for welding key components such as automotive chassis, frames, and exhaust systems. Laser welded square pipes have high strength and light weight, which can effectively improve the collision resistance of cars and achieve lightweight body, in line with the development trend of energy conservation and emission reduction in the automotive industry.

• Furniture manufacturing field

Modern furniture design increasingly emphasizes simplicity, fashion, and durability. Square pipes are commonly used materials in furniture manufacturing, and their welding quality directly affects the appearance and service life of furniture. The welding seam of the square laser welded pipe machine is smooth and flat, and can be directly used for furniture assembly without grinding, especially suitable for the processing of furniture products such as dining tables, chairs, shelves, wardrobe frames, etc.

• Industrial manufacturing and pipeline field

In the field of industrial manufacturing, square laser welding machines are used for welding and processing products such as mechanical equipment frames, industrial pipelines, condenser pipes, and petroleum pipes. Industrial equipment frames require extremely high precision and stability. Laser welding can ensure the assembly accuracy and structural strength of the frame, reducing vibration and noise during equipment operation; In the field of industrial pipelines, especially square pipelines that transport liquids and gases, the sealing and corrosion resistance of laser welding can effectively avoid leakage problems and ensure the safety and stability of industrial production.

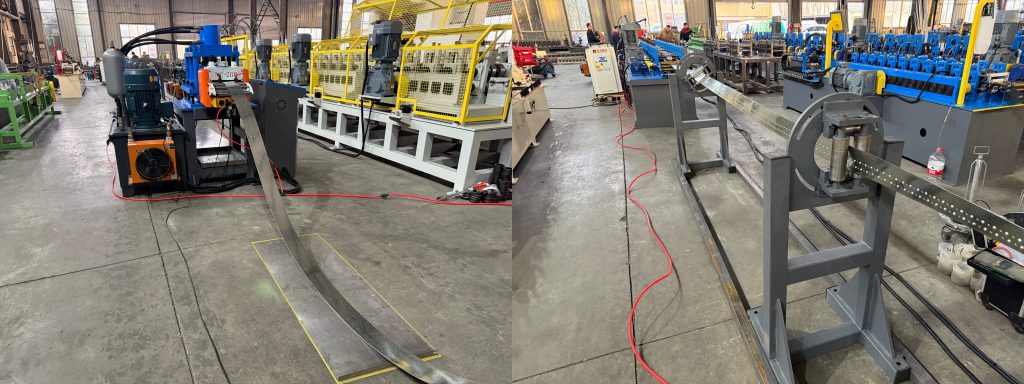

Finished product image:

Product Attributes :

|

Machine HG-32 |

Machine HG-50 |

||

| Wall thickness | 0.4-2.5mm | Wall thickness | 0.4-2.5mm |

| Pipe diameter | 10-45mm | Pipe diameter | 10-45mm |

| Round pipe | Max. OD-45mm,

Min.OD-10mm |

Round pipe | Max. OD-45mm,

Min.OD-10mm |

| Square pipe | Max.-35*35mm,

Min.-10*10mm |

Square pipe | Max.-35*35mm,

Min.-10*10mm |

| Rectangular pipe | Max.-30*40mm,

Min,-10*10mm |

Rectangular pipe | Max.-30*40mm,

Min,-10*10mm |

|

Machine HG-76 |

Machine HG-127 |

||

| Wall thickness | 0.4-2.5mm | Wall thickness | 0.4-2.5mm |

| Pipe diameter | 10-45mm | Pipe diameter | 10-45mm |

| Round pipe | Max. OD-45mm,

Min.OD-10mm |

Round pipe | Max. OD-45mm,

Min.OD-10mm |

| Square pipe | Max.-35*35mm,

Min.-10*10mm |

Square pipe | Max.-35*35mm,

Min.-10*10mm |

| Rectangular pipe | Max.-30*40mm,

Min,-10*10mm |

Rectangular pipe | Max.-30*40mm,

Min,-10*10mm |

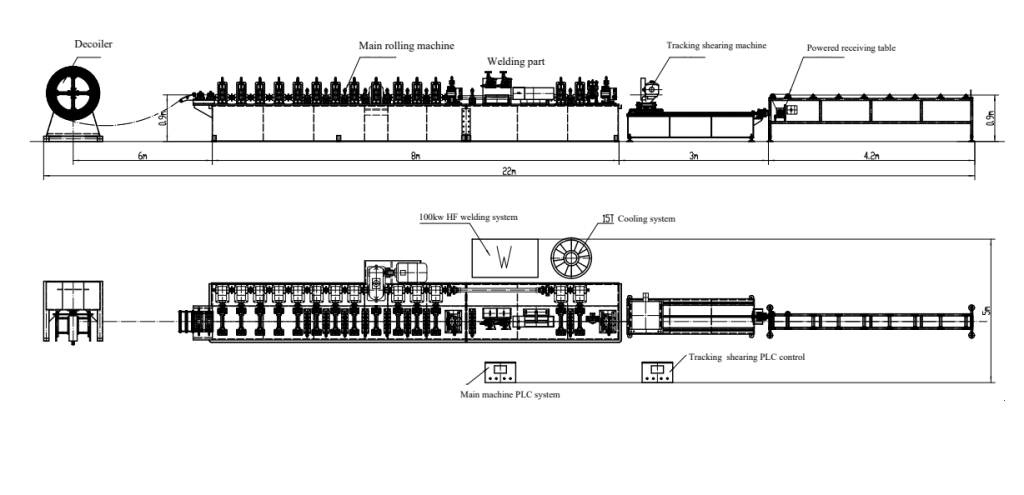

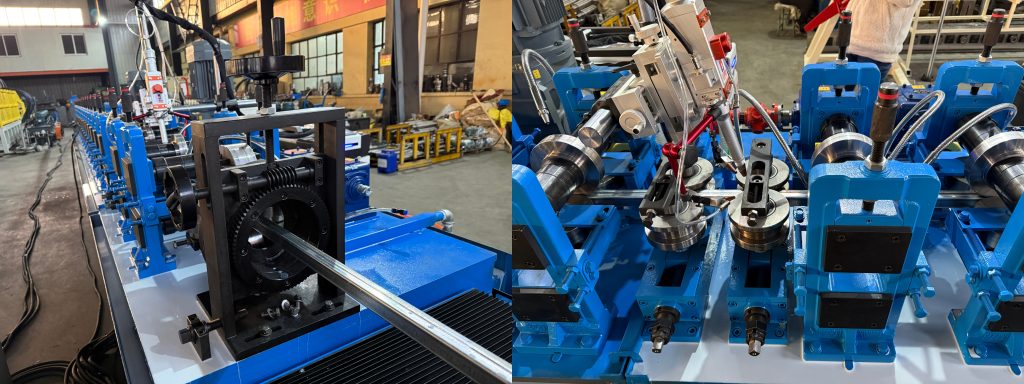

working flow:

Core advantages :

1.High welding accuracy and excellent weld quality

2. High welding efficiency and lower production costs

3. Wide adaptability, flexible and convenient operation

4. Strong stability, safe and environmentally friendly