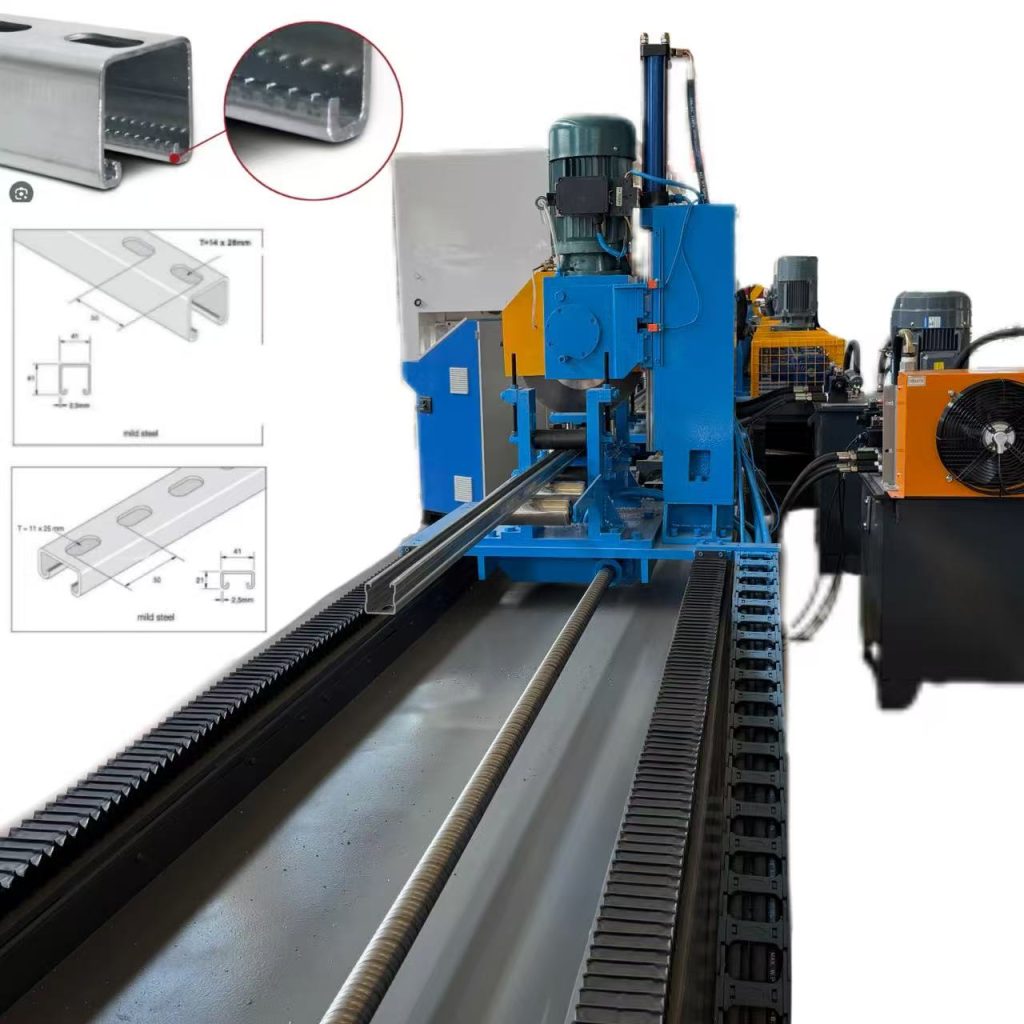

Solar Strut Channel Machine Bracket Making Machine is a support structure designed specifically for solar photovoltaic systems. Its core function is to ensure the stability of photovoltaic modules under extreme working conditions such as earthquakes and strong winds, reduce system failure rates, and improve safety and reliability. It is widely used in various photovoltaic power stations in earthquake prone areas.

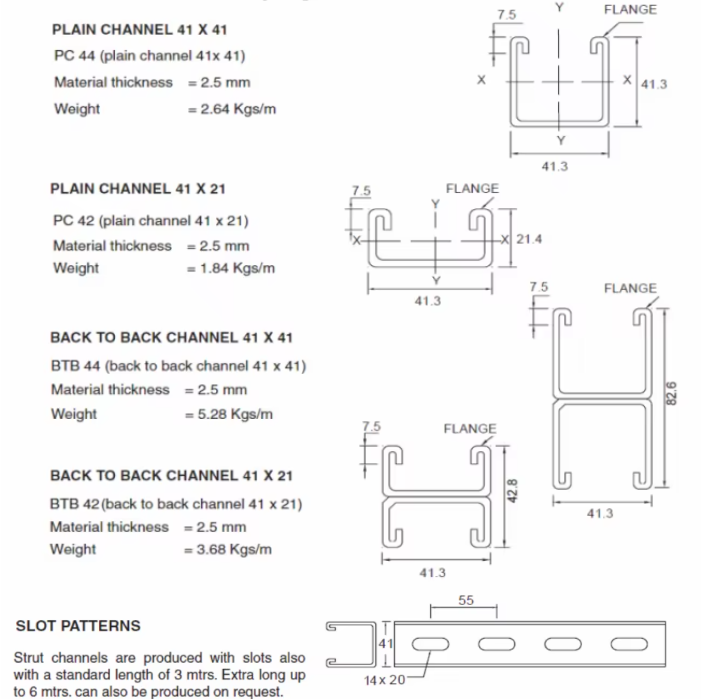

Pattern diagram:

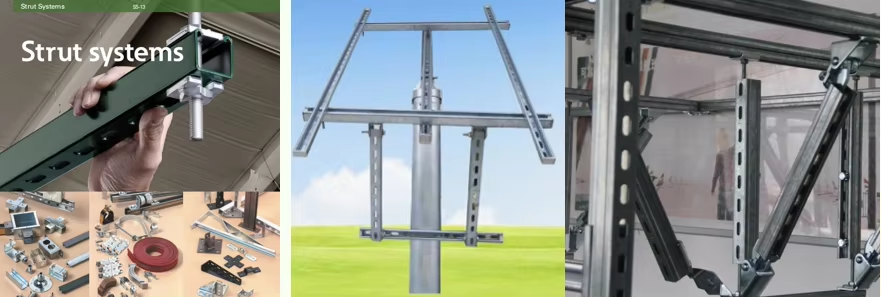

Application scenarios:

• Photovoltaic power stations in earthquake prone areas:

ensuring stable operation of power stations during earthquakes, reducing equipment damage and energy loss.

• Large scale ground photovoltaic projects:

in open areas such as deserts and mountains, to cope with complex working conditions such as strong winds and earthquakes and improve system reliability.

• Industrial, commercial, and civilian rooftop photovoltaics:

Urban building roofs meet seismic requirements while adapting to building structures without affecting building safety.

• Special scenario photovoltaic systems:

such as water-based photovoltaics and high-altitude photovoltaic power stations, balancing anti-corrosion, seismic resistance, and environmental adaptability.

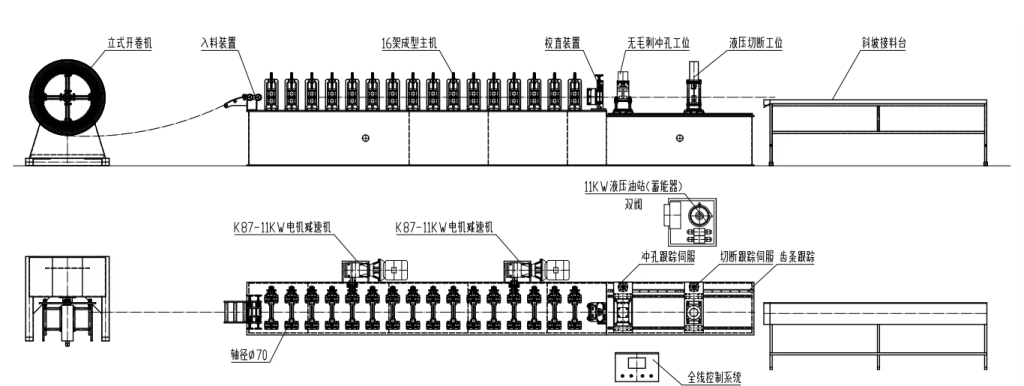

working flow:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

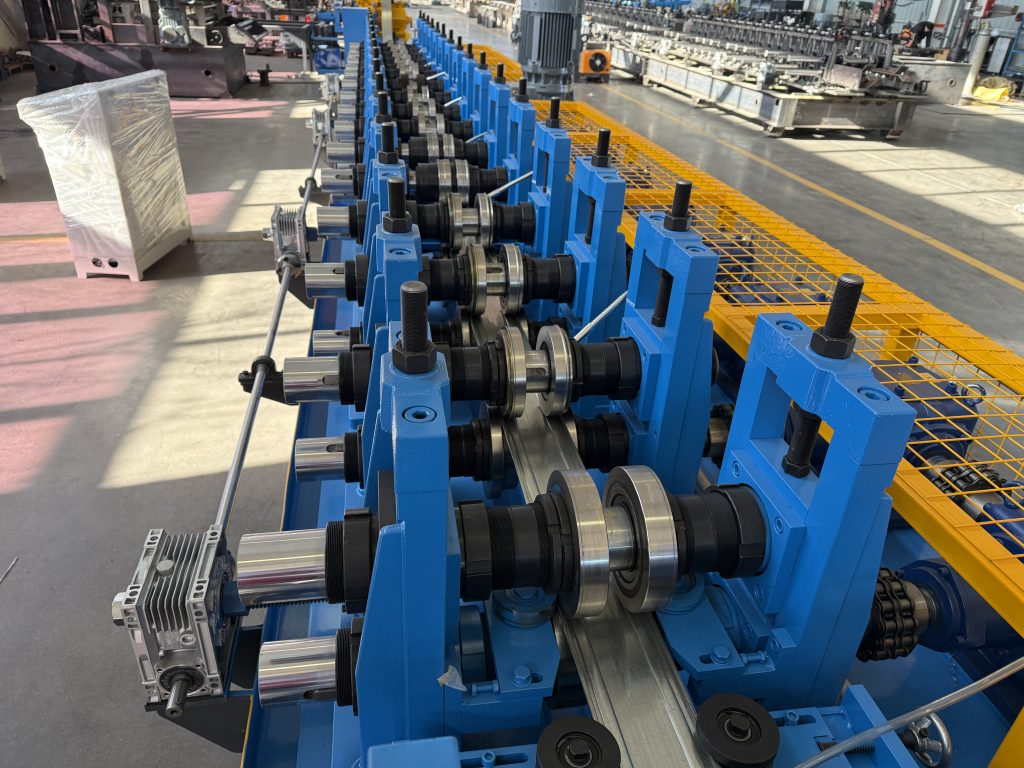

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

60mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 6.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Core advantages:

1.Structural design optimization:

By adopting optimized mechanical structures, it can accurately adapt to the installation requirements of photovoltaic panels, ensure the stable fixation of components, and enhance the overall wind and seismic resistance of the system.

2.Lightweight and high-strength materials:

Mainstream materials include aluminum alloy and steel (such as hot-dip galvanized steel and profiled steel). Aluminum alloy brackets have the characteristics of corrosion resistance, light weight, beauty and durability, and are suitable for roofs of civil buildings; Steel brackets have high load-bearing capacity, stable performance, and easy installation, and are widely used in power stations and industrial projects.

3.Quick installation and convenience:

The design focuses on construction efficiency, such as using guide rails and clamps (such as “wave plate clamps”) to achieve non-destructive and fast assembly, reducing on-site drilling and welding, and shortening the construction period.

4.Environmental adaptability and durability:

The surface is often subjected to rust prevention treatments such as oxidation and hot-dip galvanizing to enhance weather resistance; Some designs, such as composite rock wool color steel plates, combine insulation, heat insulation, and fire resistance to adapt to complex climates.