Application empowers all industries to embark on a new journey of upgrading:

With excellent performance and flexible adaptability, U Purlin Stud Drywall Profile Roll Forming Machine have been widely used in multiple core fields such as construction, mining, new energy, and transportation, becoming an important support for promoting high-quality development in the industry.

• In the field of mine support:

U Purlin supports are the “steel backbone” that ensures the safety of underground operations in coal mines, metal mines, and other mine roadway support projects. The U Purlin arch frame processed by the U Purlin steel machine has high precision and sufficient strength, which can effectively withstand the ground pressure of the roadway and prevent collapse accidents.

• In the field of building materials:

In the construction of industrial plants, warehouses, sports venues, large exhibition halls and other buildings, U Purlin, as the core material of steel structure frames, weighs only 1/5 of traditional reinforced concrete, but its bearing capacity is increased by 30%. The profiles processed by U Purlin Stud Drywall Profile Roll Forming Machine can significantly shorten the construction period and reduce the amount of building materials used.

• In the field of new energy:

In new energy projects such as photovoltaics and wind power, U Purlin brackets need to withstand wind, sun, and heavy equipment loads for a long time, with extremely high requirements for strength and corrosion resistance. After optimization design, the strength is increased by 20% under the same weight, and the corrosion resistance period is extended to 25 years after surface galvanizing treatment.

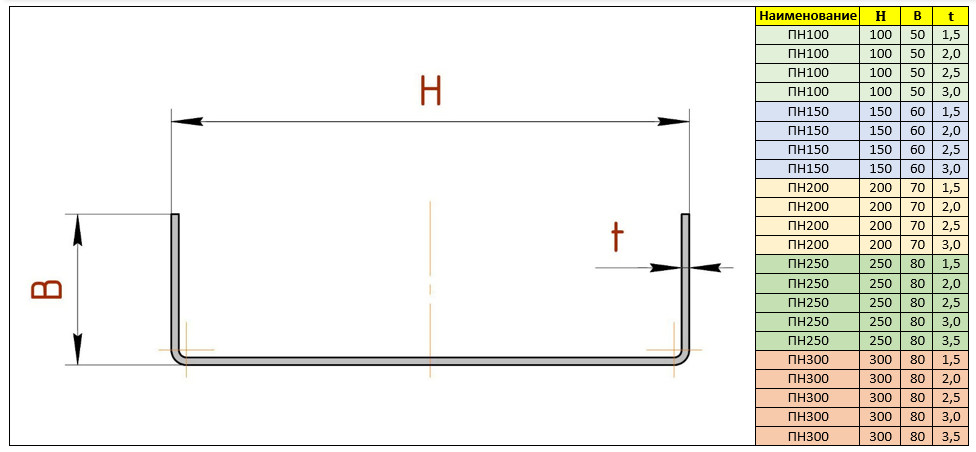

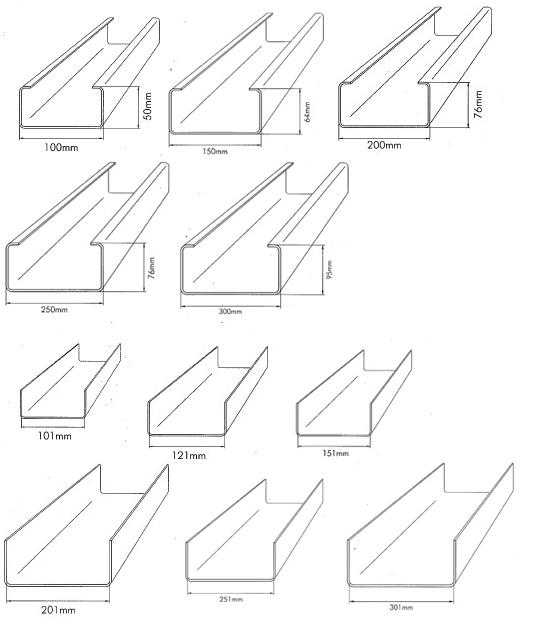

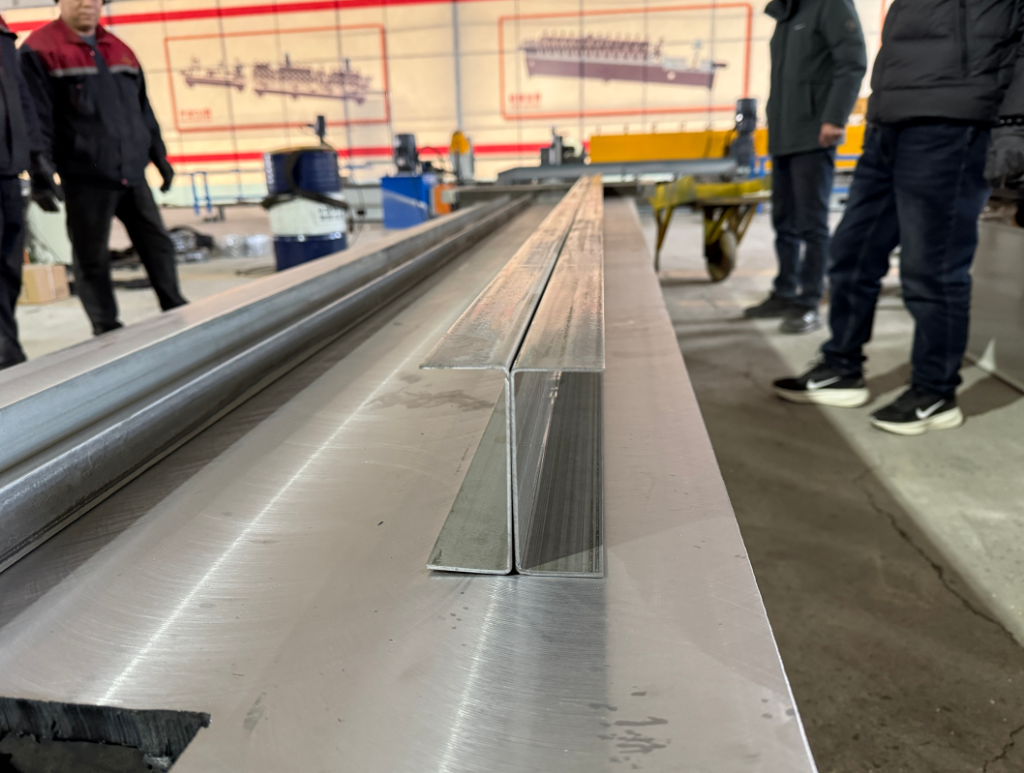

Profile drawing as below:

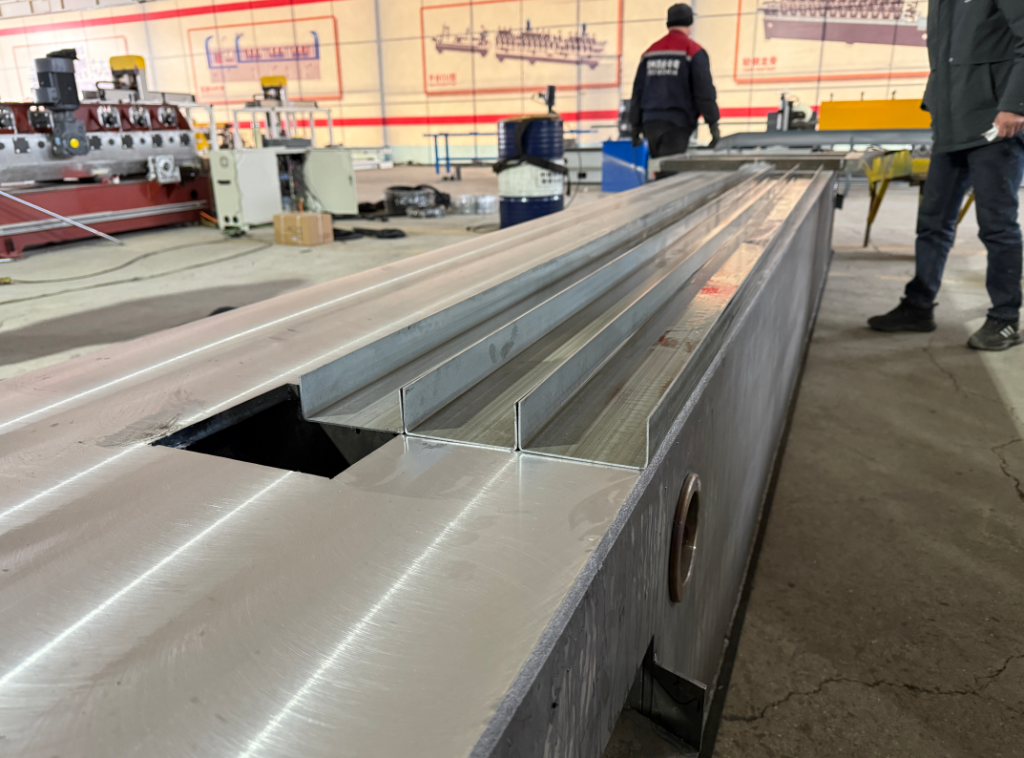

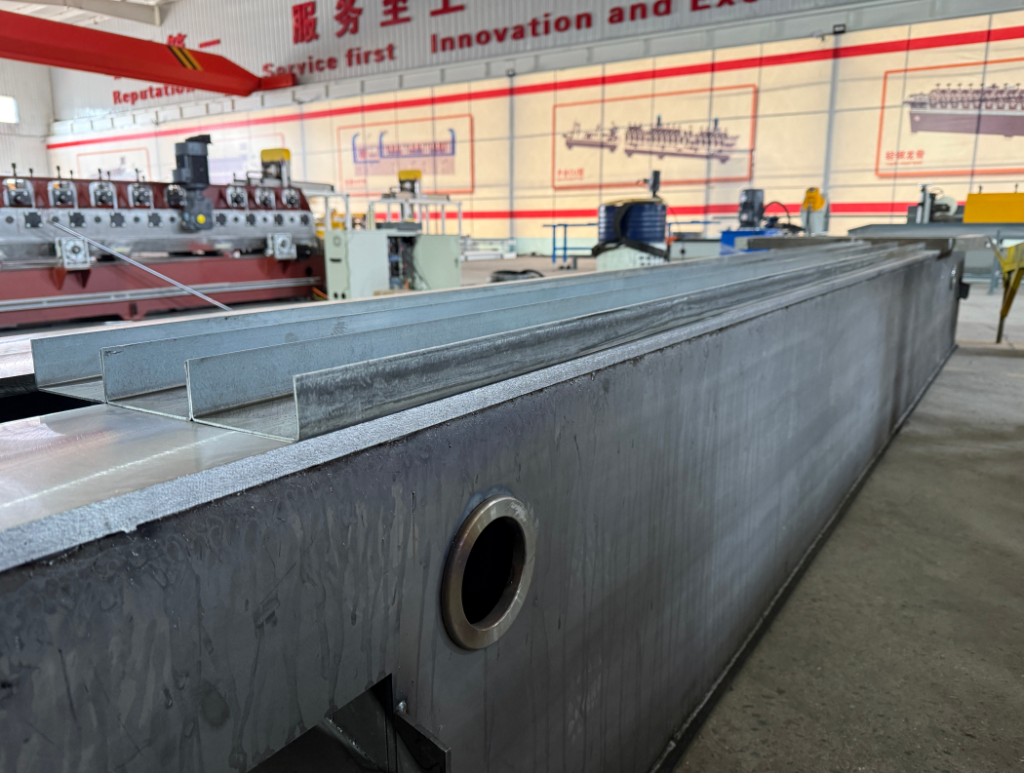

Machine Introduction:

In the wave of modern industrial production and engineering construction, U Purlin has become an indispensable core profile in fields such as construction, mining, and new energy due to its excellent mechanical properties, high strength to weight ratio, and unique cross-sectional advantages. The quality and efficiency of U Purlin depend on the hard strength of the processing equipment. A high-quality U Purlin Stud Drywall Profile Roll Forming Machine is not only an accelerator of production efficiency, but also a guardian of product accuracy. It is a key equipment for enterprises to reduce costs, increase efficiency, and strengthen engineering safety.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

We also have the economic type machine with lower speed

|

||

Multi dimensional advantages, reshaping a new ecosystem of efficient production

Compared to traditional processing equipment and manual operation, U Purlin Stud Drywall Profile Roll Forming Machine have built a comprehensive competitive advantage through technological innovation, creating tangible value increments for enterprises.

1. Efficient and energy-saving, doubling production capacity:

The equipment is equipped with a 15 kW cycloidal pinwheel motor and a dedicated hydraulic system, which has strong power and reasonable energy consumption. A single bending only takes 30 seconds, and the rolling speed can reach 4.3 meters per minute. It can complete the processing of 30 U-shaped steels per hour, and the daily production capacity is increased by more than 40% compared to traditional processes. The full process automation processing significantly reduces labor input. The traditional process requires 3 people to collaborate for 2 hours to complete the workload, and a single person can operate the equipment in only 20 minutes, reducing labor costs by more than 60%.

2. Accurate and stable, with consistent quality:

Relying on PLC intelligent control and laser positioning technology, the forming error of the equipment can be controlled within 0.5 °, and the accuracy of cross-sectional dimensions, straightness, and curvature all meet the highest industry standards. The finished product has good flatness and excellent mechanical properties, which can directly meet the requirements of high-strength engineering applications. After 72 hours of continuous operation testing, the equipment has a failure rate of less than 0.3% and can still work stably in extreme environments ranging from -20 ℃ to 50 ℃, adapting to various complex production scenarios.

3. Safe and convenient, worry free operation and maintenance:

The equipment is equipped with dual safety protection devices to eliminate safety hazards during operation and ensure the personal safety of operators. The whole machine operation process is minimalist, requiring only three steps to complete the processing: parameter preset, mold matching, and one click start, with low technical requirements for operators. Simultaneously providing remote diagnosis and on-site maintenance services, customized process solutions, ensuring worry free production for enterprises.