Expressway Soundproofing Barrier Panel Roll Forming Machine

The rapid development of the automobile industry and the advancement of urbanization have brought tremendous opportunities for the development of expressways in China. The main railway lines are under strained transportation capacity, and some regions suffer from poor access to inbound and outbound channels, thus expressways play a crucial role in transportation.

As a result, China’s expressway industry is in a phase of industrial expansion, facing the opportunity of sustained prosperity. Due to the large traffic volume and high speed on expressways, relatively high traffic noise is generated.

At present, the concept of environmental protection is increasingly incorporated into the construction of expressways.

To prevent noise from disturbing residents living around the highways, high-speed Soundproofing Barrier Panels are installed in a targeted manner based on environmental characteristics, which can play a significant role in enhancing road aesthetics and protecting the environment.

Expressway Soundproofing Barrier Panels are also known as sound insulation walls, sound-absorbing barriers, and sound deadening walls.

They adopt combined sound insulation barriers consisting of louver perforated sound-absorbing panels and transparent materials, with folded corners on the top, boasting an attractive appearance without blocking the view. The road Soundproofing Barrier Panels commonly installed on expressways are mixed sound-absorbing and sound-insulating products.

According to acoustic theory, sound has the characteristic of diffracting through the upper part of the screen body. Therefore, a structure with sound absorption at the upper and lower parts and sound insulation in the middle is adopted in the design, which can effectively reduce the diffraction of noise.

The middle part of the sound insulation barrier uses a transparent reflective sound insulation panel, which can effectively interrupt the propagation path of sound waves.

The average sound insulation of road Soundproofing Barrier Panels is 37dB, and the average sound absorption coefficient is 0.84. Moreover, they are water-resistant, heat-resistant, and UV-resistant, and will not deteriorate in performance or have abnormal quality due to changes in rainwater and temperature.

The main parameters of the machine

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.8 -1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

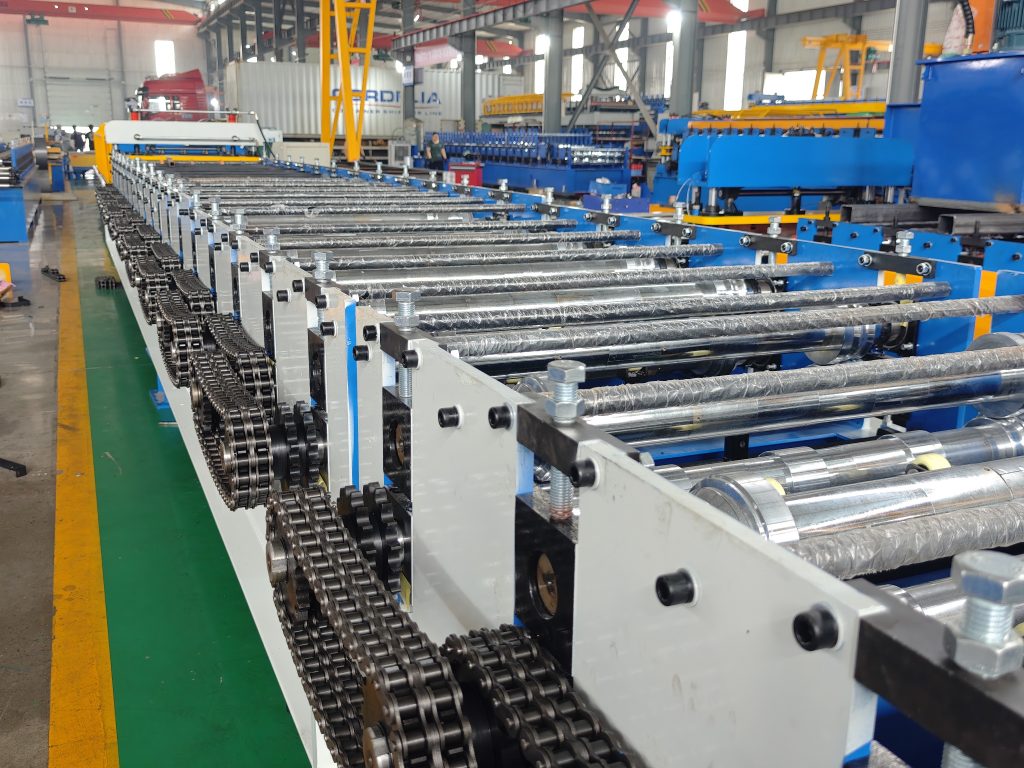

3.Main body

|

Roller station

|

32rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Recommended related machine

Some pictures of practical applications