Work flow of the machine

https://www.youtube.com/watch?v=T2hRPY_aZk4

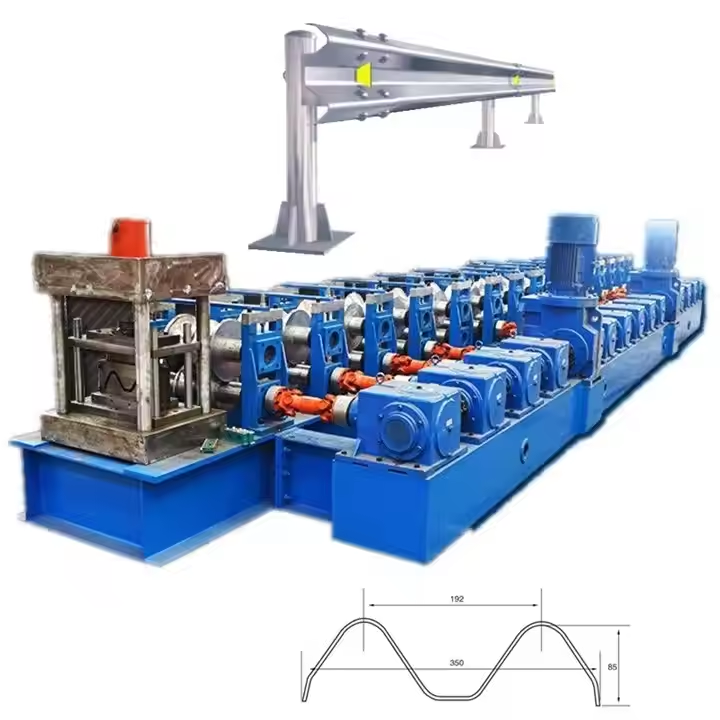

Introduction of Highway Corrugated Beam Guardrail

Highway Corrugated Beam Guardrail, as the primary form of semi-rigid guardrails, is a continuous structure where corrugated steel guardrail plates are mutually spliced and supported by columns. It utilizes the deformation of the subgrade, columns, and crossbeams to absorb collision energy, compelling out-of-control vehicles to change direction, return to the normal driving path, and prevent them from rushing off the road—thereby safeguarding vehicles and passengers while minimizing accident-induced losses.

Highway Corrugated Beam Guardrail combines rigidity and flexibility, featuring strong collision energy absorption capacity, excellent visual guidance function, and harmonious coordination with road alignments. It has an aesthetic design, adapts to small-radius curves, and allows for easy replacement of damaged sections. The combined type of this guard rail is suitable for narrow central medians, while reinforced Highway Corrugated Beam Guard Rail is recommended for sections where vehicle run-off-road (or bridge) may cause severe consequences. Its advantages include good impact resistance, low cost, long service life, higher safety, and environmental friendliness.

Main Characteristics of the Production Line:

1. High Safety Performance

It eliminates safety hazards and work-related accidents caused by traditional processes such as plate shearing, slitting, punching, and bending.

2. High Production Efficiency

It saves manpower, material resources, and management links in multiple processes, reduces intermediate operation steps, and improves production efficiency by 5-10 times compared with traditional processes.

3. High Degree of Automation

Controlled by PLC computer, it features simple operation without manual calculation of dimensions like hole spacing and length of support profiles. The production line is fully automated and requires no human intervention.

4. High Profile Precision

The profiles have higher dimensional accuracy and more uniform and beautiful appearance than those produced by manual punching and bending.

Main roll forming machine

| Roller station | 16 rows(As your requirement) | ||

| Diameter of shaft | φ95mm | ||

| Material of rollers | 45# steel with tempering | ||

| Machine body frame | 400 H steel | ||

| Drive | Gearbox transmission | ||

| Dimension(L*W*H) | 18500*1200*1500mm | ||

| Weight | 15T |

Recommend related machine