In fields such as steel structure construction, bridge engineering, and container manufacturing, hat shaped steel has become the preferred core load-bearing component due to its unique cross-sectional structure, excellent load-bearing performance, and space utilization. And an efficient, precise, and stable forming equipment is the key to ensuring engineering quality and construction efficiency – the Omega Hat Channel Roll Forming Machine Drywall Steel Profile Making Machinery, specially designed for mass production of high-quality hat shaped steel, reshaping industry standards with technological innovation!

Widely applied, covering core scenarios of the entire industry

1. The purlins and supporting components of steel structure factories and warehouses

2. Auxiliary load-bearing structures for bridge engineering

3.Formation of the skeleton of containers and carriages

4.Customized processing of photovoltaic brackets and curtain wall keels

5. Specialized steel production for mechanical manufacturing and equipment bases

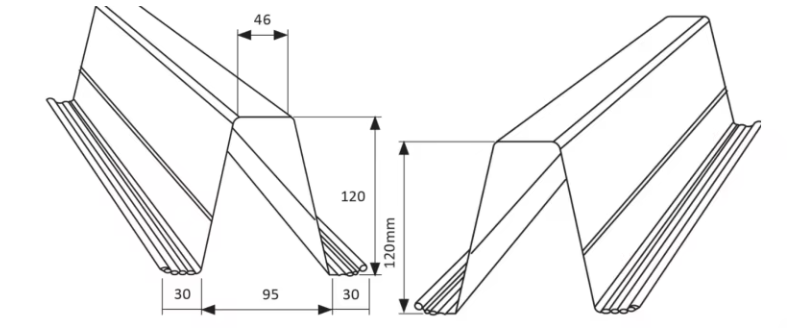

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

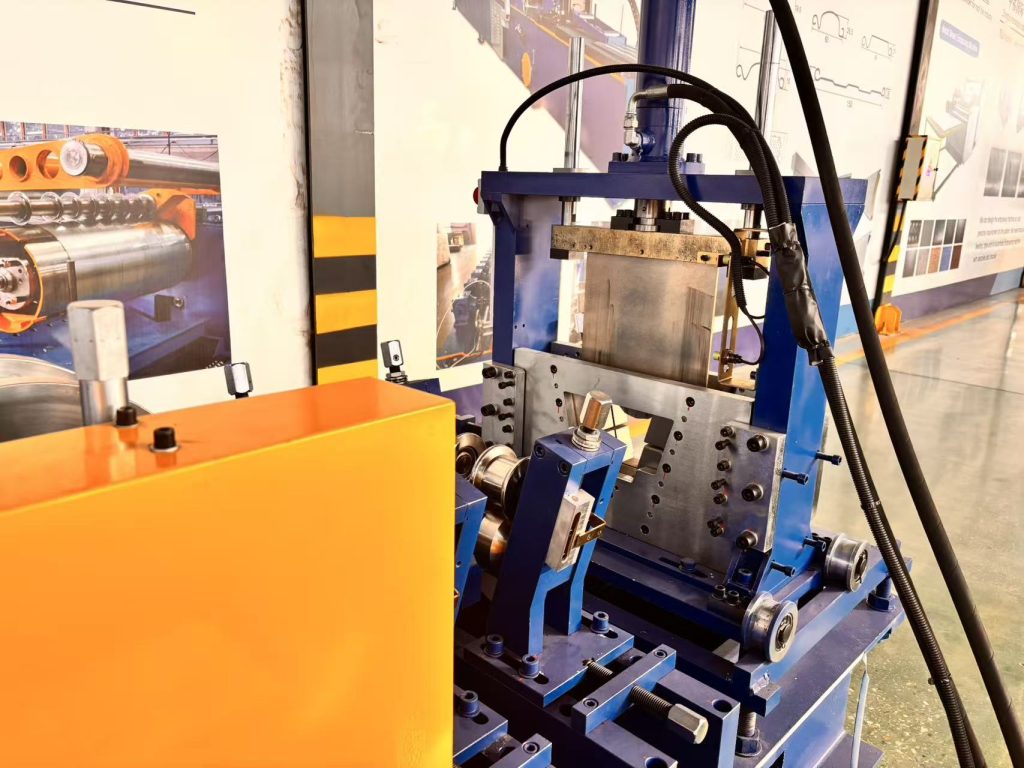

3.Main body

|

Roller station

|

16 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Core advantages, strength surpassing traditional equipment

• High precision molding, with errors approaching zero

Adopting a CNC servo system and precision forming roller group, the entire process is automatically controlled, from steel strip unwinding, leveling, forming to cutting, with an integrated completion of forming accuracy of ≤± 0.3mm, uniform cross-sectional size, smooth appearance without burrs, fully meeting national standards and high-end industry standards, without the need for secondary processing, and directly connected to engineering installation.

• Efficient mass production, doubling and increasing production capacity

Optimizing the transmission design based on the characteristics of the hat shaped steel structure, the production speed can reach 8-15m/min, far exceeding the traditional single machine capacity limit of 3-5m/min; Supporting continuous and uninterrupted operations, with a daily production capacity of up to 1000+meters, it can easily meet the centralized supply needs of large-scale projects and significantly shorten project cycles.

• Multi functional adaptation, flexible response to diverse needs

We can customize different specifications (height 50-300mm, thickness 2-8mm) of hat shaped steel according to customer needs, compatible with Q235, Q355 and other materials of steel strips; Equipped with a fast mold changing system, the mold changing time is ≤ 30 minutes, which can meet both large-scale standardized production and small batch customized orders, reducing equipment investment costs with one machine for multiple uses.

• Energy conservation and consumption reduction, resulting in a direct 20% decrease in operating costs

Adopting variable frequency speed regulation technology, energy consumption is allocated according to demand, saving 15% -20% compared to traditional equipment; The body is welded with high-strength steel, and the rollers are strengthened by heat treatment, which is wear-resistant and durable, with a low failure rate. The annual maintenance cost is less than 3% of the total equipment price, making long-term use more cost-effective.

• Intelligent control, worry free, labor-saving, and safer

Equipped with a touch control panel, parameter settings and production monitoring are clear at a glance, making it easy for beginners to get started quickly; Equipped with multiple safety devices such as overload protection and emergency stop, the entire process is unmanned to avoid manual operation risks and ensure production safety.