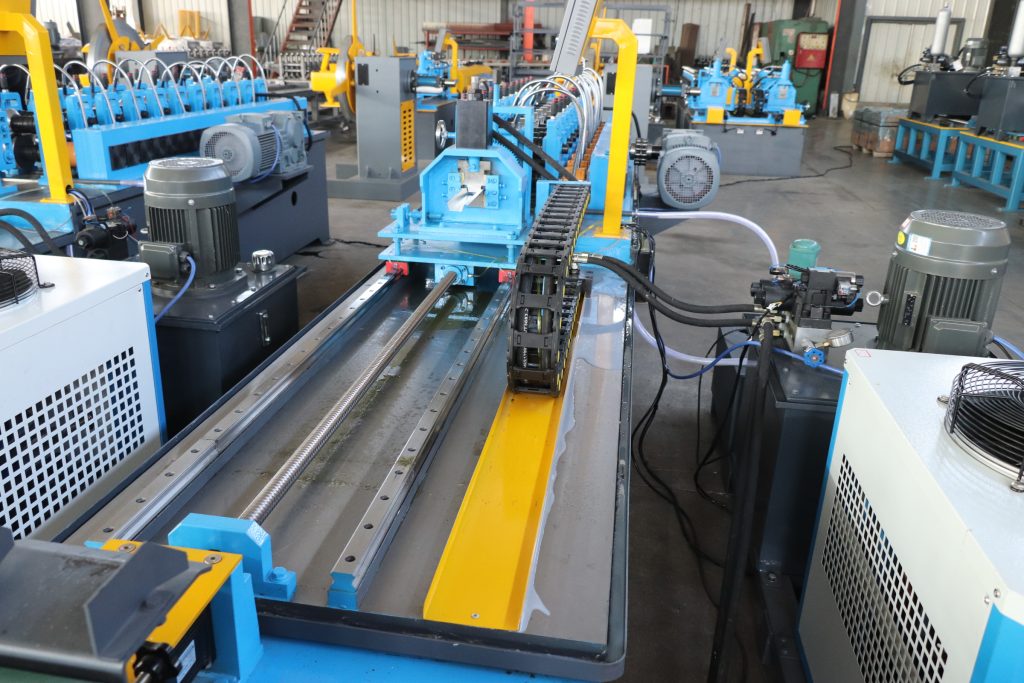

Hat Shaped Ceiling Stud Omega Profile Making Machine

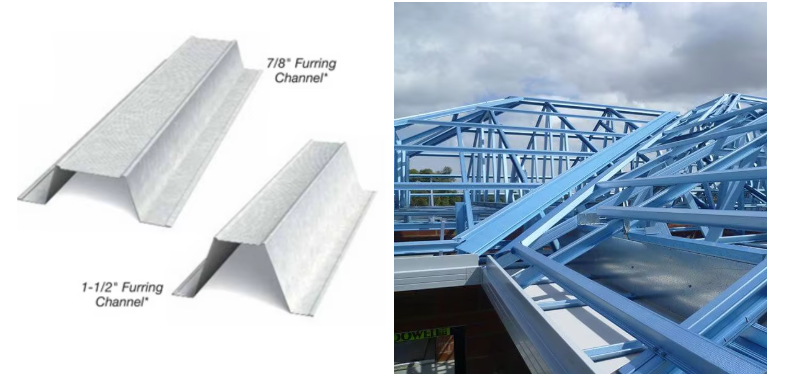

The Hat Shaped Ceiling Stud Omega Profile Making Machine is an automated processing equipment specifically designed for the construction and decoration industry. It is primarily used for producing U-shaped and hat-shaped cross-section keels, such as ceiling keels and vertical partition keels. As a key device, it replaces traditional manual processing and enhances the production efficiency and precision of keels, making it widely suitable for various decoration project scenarios, including residential and commercial interior work.

Four core advantages, reshaping the standard of keel processing

1. Accurate shaping, with errors approaching zero

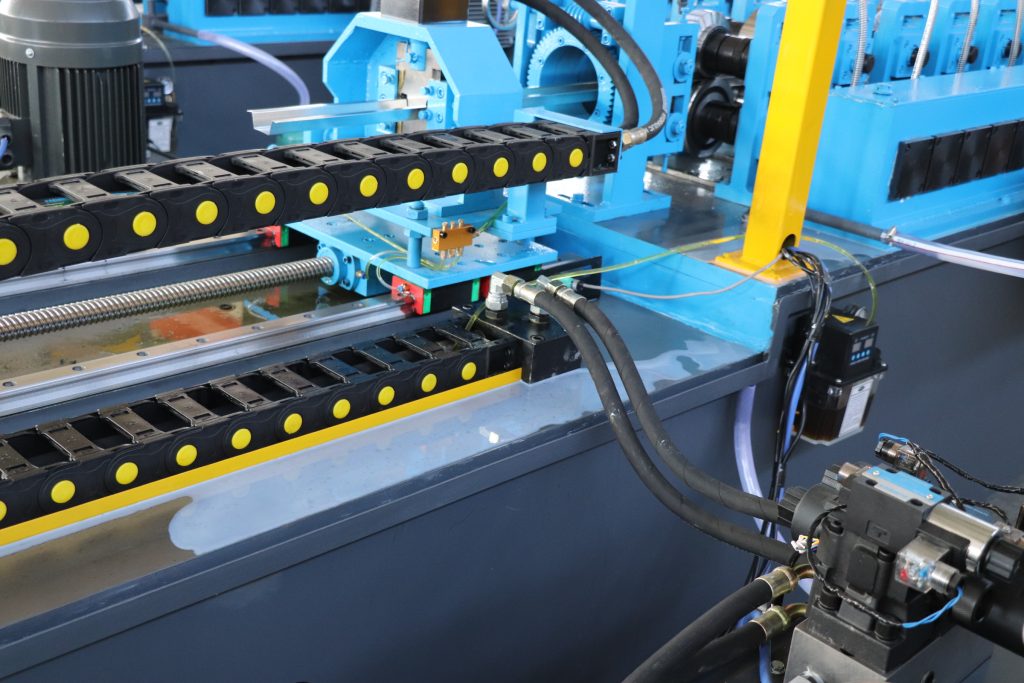

Adopting a CNC servo system and high-precision guide rail design, the feeding accuracy reaches ± 0.1mm, the cutting error is ≤ 0.5mm, and the formed keel section is regular, with sharp edges and tight joints, avoiding loosening and cracking problems during later installation from the source, ensuring better engineering quality.

2. Durable and durable, suitable for multi material processing

The body is made of thickened steel plates welded together, which has strong rigidity and low vibration; The key components (cutting tools, molds) are made of high-strength alloy steel, which has undergone quenching treatment and is wear-resistant and wear-resistant. It can continuously process various materials such as galvanized steel strips and cold-rolled steel plates (thickness 0.5-1.2mm), and its service life is extended by more than 30% compared to ordinary equipment, reducing maintenance costs in the later stage.

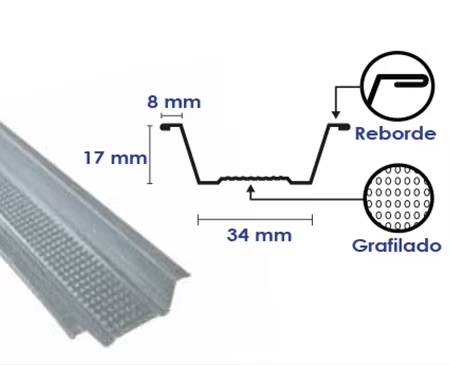

3. Flexible and adjustable to meet diverse needs

Support customization of various specifications of hat shaped keels (width 50-100mm, height 30-80mm), with quick adjustment of size, hole spacing, and cutting length through the touch screen, without the need to replace the entire set of molds, suitable for keel needs in different scenarios such as home decoration, tooling, office buildings, hotels, etc. One device can handle multiple types of projects.

4. Energy saving and worry free, maximizing cost-effectiveness

The overall power of the device is only 5.5-7.5KW, which saves 20% energy compared to similar equipment; Equipped with an automatic lubrication system and overload protection device, the operation is stable and fault free, and the consumable loss rate is controlled within 1%. Long term use can save a lot of steel costs, and the investment return period is as short as 6-8 months.

Applicable scenarios: Industry wide coverage

• Decoration company: Shorten construction period, improve project delivery efficiency, and enhance market competitiveness;

• Engineering construction team: reduce labor dependence and rework losses, accurately control project costs;

• Building materials distributor: independently processing keel, producing according to demand to avoid inventory backlog and increase profit margin;

• Applicable project types: home decoration ceilings, office partitions, large public construction projects such as shopping malls/hospitals/hotels.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||