Product video:

Product Description:

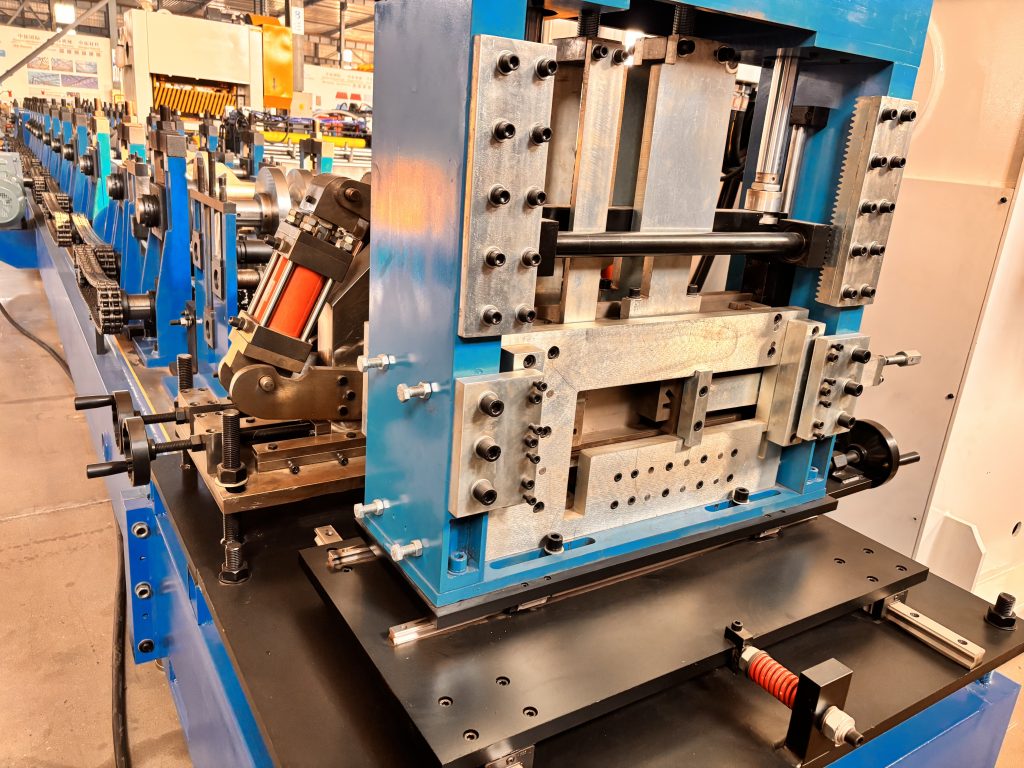

The CZ Purlin Structural Steel Profile for Eave Struts Making Machine is an intelligent cold bending forming equipment designed for efficient production of steel structural components. Its core function is to achieve integrated forming of C-shaped steel and Z-shaped steel, support multi specification and multi material processing, and can complete C/Z-shaped free switching without changing molds. It is widely suitable for large-scale production and customized needs, and is a core production equipment in the fields of prefabricated buildings, green energy, etc.

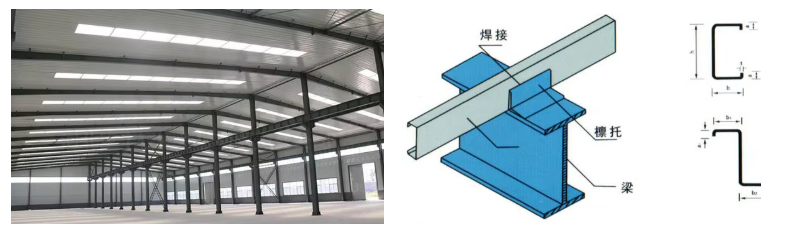

Application scenarios:

The CZ steel produced by this equipment, as the core load-bearing component, is widely used in:

• Industrial buildings: factory purlins, workshop skeleton, column free warehouse load-bearing structures;

• Warehouse logistics: storage shelves, logistics turnover racks, three-dimensional warehouse keel;

• Green energy: photovoltaic brackets, wind power tower auxiliary structures;

• Transportation and Municipal Administration: Traffic noise barriers, subway platform keels, highway guardrails;

• Agricultural architecture: multi span greenhouse skeleton, load-bearing structure of breeding greenhouse.

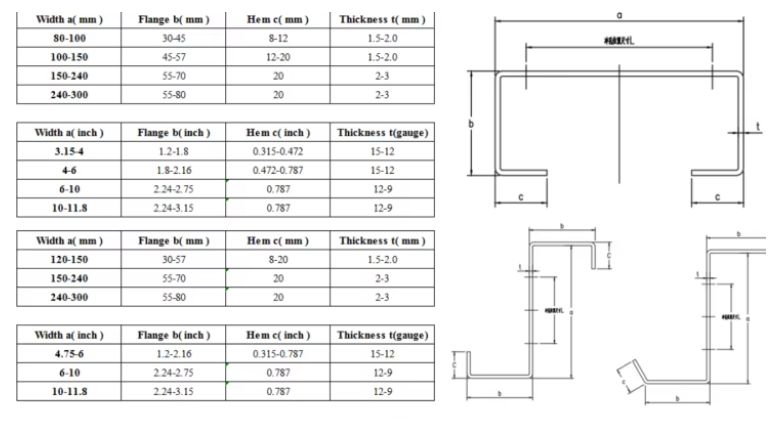

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||