Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.7-1.2mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

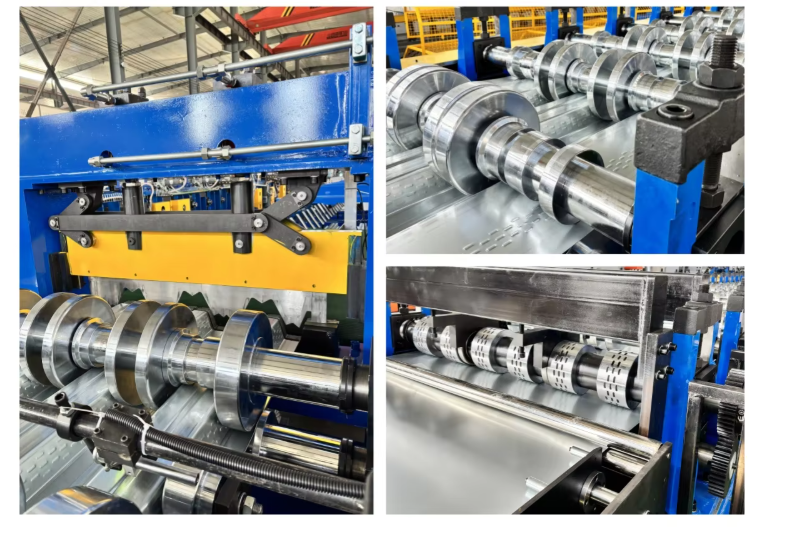

3.Main body

|

Roller station

|

33 rows(As your requirement)

|

||

|

Diameter of shaft

|

90mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW*2 sets,Siemens brand

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

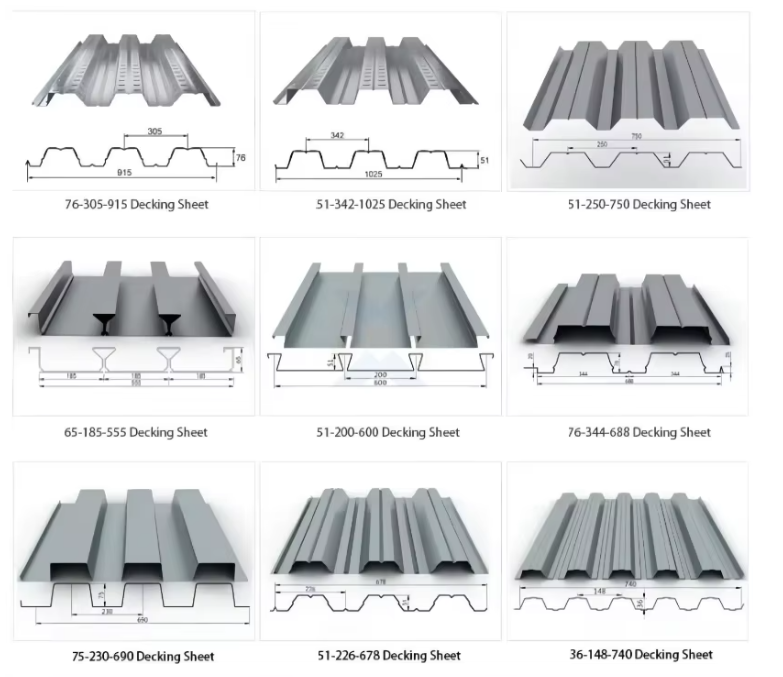

Product Introduction:

In the wave of rapid development of the modern construction industry, as an important building component, the floor deck plays a key role in the floor structure. The floor deck machine, as the core equipment specializing in the production of floor decks, has become an indispensable and important force in the construction industry with its unique performance and wide range of applications. The floor deck machine is a specialized production equipment integrating mechanical design, automation control and other technologies. It uses steel as the main raw material, and through a series of continuous processing processes, the flat steel is rolled into a floor deck with a specific cross-sectional shape. Its overall structure is precise, mainly composed of discharging mechanism, forming host, cutting device, control system and other parts, each part works together to ensure the smooth and efficient production process.

The characteristics of the floor decking machine are very prominent, first of all, the efficient production capacity. The traditional way of making floor decks relies on manual operation, which is not only slow, but also labor-intensive. The floor deck machine realizes fully automated production, from the transportation of raw materials to the forming and cutting of the floor deck, the whole process is completed in one go, and the floor deck can be produced several meters or even more than ten meters per minute, which greatly improves the production efficiency and can quickly meet the large demand for floor deck for large-scale construction projects.

Secondly, excellent production accuracy is another highlight. The cross-sectional shape and dimensional accuracy of the floor deck directly affect its mechanical performance and installation quality in the building. The floor deck machine adopts high-precision roll mold and advanced servo control system, which can accurately control each forming process, so that the cross-sectional shape of the floor deck produced is regular, and the size error is controlled within a very small range, which ensures that the floor deck can be perfectly spliced during construction and installation, and effectively improves the stability of the building structure.

In addition, the floor deck machine is highly flexible and adaptable. Different construction projects have different requirements for the specifications and models of floor decks, some require a wider cross-section, and some require specific wave heights and wave distances. The floor deck machine can easily produce a variety of floor decks of different specifications by replacing different roll molds and adjusting relevant parameters to meet diverse construction needs, without the need to equip production equipment separately for products of different specifications, which greatly reduces production costs.

In addition, the ease of operation and safety should not be overlooked. The floor deck machine is equipped with an intelligent control system, the operator only needs to set the relevant parameters on the control panel, and the machine can automatically complete the production process, the operation is simple and easy to understand, even a novice can master it in a short time. At the same time, the machine is also equipped with multiple safety protection devices, such as emergency stop buttons, protective fences, etc., which can effectively avoid accidents in the production process and ensure the personal safety of operators.

Application Scenarios:

In terms of application scenarios, the floor deck produced by the floor deck machine has a wide range of applications in the construction field. In multi-storey and high-rise buildings, the floor bearing plate is used as the permanent template of the floor slab, which can not only bear the self-weight and construction load of concrete, but also combine with concrete to form an overall stress structure, which greatly shortens the construction period of the floor slab and improves the construction efficiency. For example, in the construction of some high-rise residential and office buildings, the use of floor decks effectively accelerates the construction progress and lays the foundation for the early completion of the project.

The construction of industrial plants is also an important application area for floor decks. Industrial plants often require large spans and high bearing capacity, and the floor deck can meet the requirements of the industrial plant for the floor slab by virtue of its excellent mechanical properties. In mechanical processing workshops, storage plants and other places, the floor deck as a floor structure, can bear the weight of heavy equipment and the stacking load of goods, to ensure the safe and stable operation of the plant.

In addition, in large public buildings such as stadiums, shopping malls, convention and exhibition centers and other places, floor decks also play an important role. These buildings usually have the characteristics of large spans and large spaces, and have strict requirements for the self-weight and bearing capacity of the floor slabs. The floor deck is light in weight and high in strength, which can effectively reduce the weight of the building structure, and at the same time meet the bearing needs of the long-span floor slab, which provides convenience for the flexible layout of the internal space of the building.

To sum up, with its efficient, accurate, flexible and convenient characteristics, the floor deck machine plays an irreplaceable role in the production of floor deck, and the wide application of the floor deck in various construction scenes also further highlights the important position of the floor deck machine in the modern construction industry, and injects a strong impetus into the development of the construction industry.

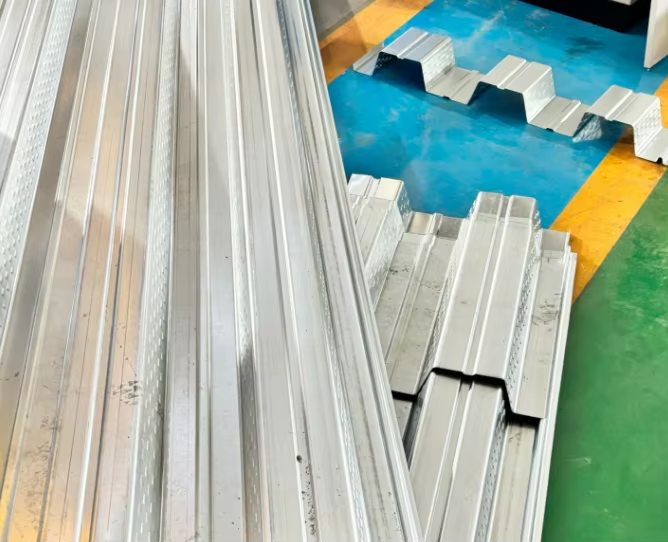

Products Display:

Product packaging:

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.