Modern Industrial Design Building Steel Structure Villa House Light Steel Frame Roll Forming Machine

https://www.youtube.com/watch?v=n5A-kW_VxO0

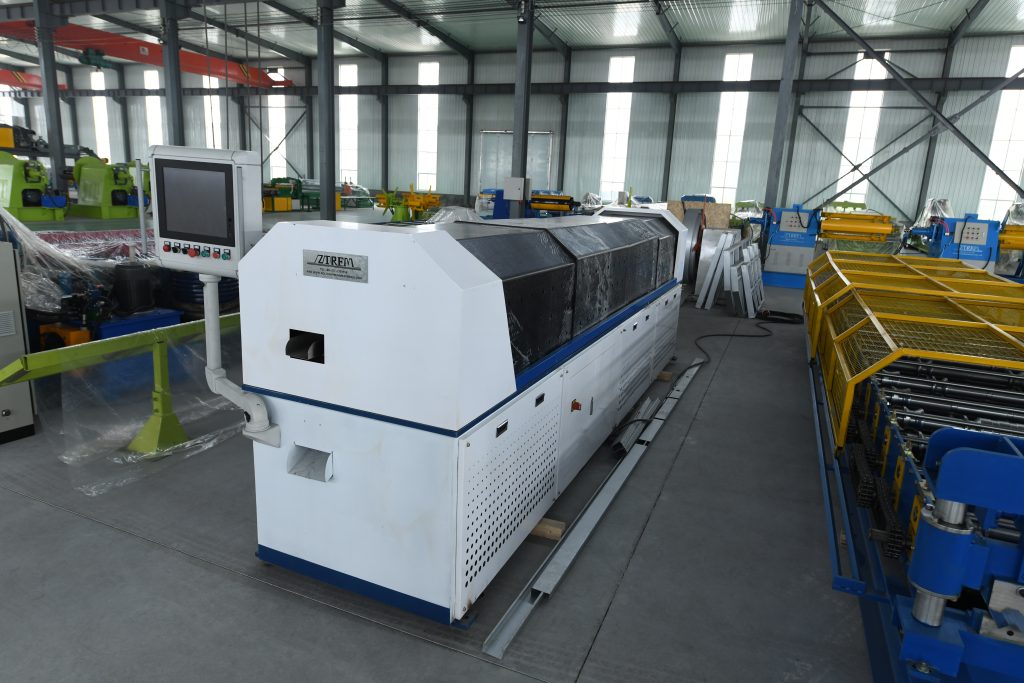

Introduction of Villa House Light Steel Frame Roll Forming Machine

Light steel frame villa keel production machine system configuration includes: Hydraulic punching system. Forming after punching ensures high precision in position and size, shortening installation time. Hydraulic cutting system. It cuts after the machine completes punching and forming, using a single-blade blanking shear.

Hydraulic system. Equipped with a cooling device to prevent overheating during long-term production and processing. Inkjet printer. Capable of printing LOGO patterns, Chinese, English, numbers, QR codes, etc. Power control system. The machine power supply adopts a three-phase four-wire system.

Auxiliary configurations of light steel frame villa keel production machine: Packing machine, which packs the produced keels for convenient transportation and classification.

Workbench. Material supporting frame. These configurations assist the main machine in production, mainly for conveying steel strips to the main machine. It adopts a jack lifting device and is equipped with an automatic start-stop device to prevent steel strips from hitting feet during feeding. It is equipped with a customized speed ratio reducer and driven by a motor.

The light steel frame villa keel machine is a piece of machine for producing light steel frame villa houses. It introduces mature New Zealand technology, with better performance and higher stability. The light steel structure buildings produced by it have the advantages of light self-weight, large span, good wind resistance and earthquake resistance, and excellent indicators in thermal insulation and sound insulation. It is an energy-saving, environmentally friendly green building system that conforms to the sustainable development policy.

Composed of a material uncoiler, guide frame, forming main machine, correction device, fixed-length cutting part, material receiving table, electrical control part, etc., it takes steel strips as raw materials and produces finished keels through continuous cold rolling forming. It is a kind of building material used to support shapes and fix structures.

The light steel frame villa keel machine adopts PLC computer precise control and full-automatic hydraulic shearing system, featuring intelligent automation, simple operation, high speed and high efficiency. The finished light steel keels have the advantages of light weight, excellent fire resistance, good impact resistance, safe and reliable structure, and good earthquake resistance, making it a new type of construction machine.

The main parameters of the machine

|

Light Steel Frame Roll Forming Machine |

|

| Equipment operation | Automatically |

| Voltage | 380V,50/60Hz or at buyer’s request |

| Thickness of material sheet | 0.75—-1.2mm(normally) |

| Width of material sheet | As drawing |

| Control system | By PLC(imported brand) |

| Cutting method | Hydraulic cutting |

| Material of roller station | Gcr12 with hard treatment |

| Formed width | As drawing |

| Working speed | 15-20m/min |

| Length of finished product | set in computer, machine will cut automatically |

| Transmission type | gears |

Application of villa keel

Recommend related machine