Below is a video for you to watch:

Product Parameters:

|

raw material

|

PPGI

|

|

material thickness:0.32-0.8mm

|

|

|

machine frame

|

350#H steel frame welded

|

|

machine structure

|

vertical arch frame structure

|

|

material of rollers

|

45# steel chromed treatment (Cr Thickness:0.05mm), anti-corrosion, increase hardness, ensure the precision and good abrasion performance

|

|

forming stations

|

14 stations

|

|

diameter of shafts

|

φ80mm

|

|

material of shafts

|

45# steel tampering treament prevent deformed and improve the hardness

|

|

forming speed

|

about 0-8m/min

|

|

voltage

|

380v 50hz 3ph or as required

|

|

transmission

|

gear box transmission

|

|

material of gear box: iron casting

|

|

|

material of gear:20 Crmnti

|

|

|

the connection between gear boxes are chains

|

|

|

gear box will connect with the rolling station one for one

|

|

|

advantage : can improve the speed directly after cutting

|

|

|

work power

|

11kw (gear reducer and servo motor driving)

|

|

cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|

cutting type

|

hydraulic cutting

|

The glazed tile roof profile forming machinery is mainly used for producing glazed tiles and other building decoration materials. This device uses galvanized steel plates, color steel plates, or aluminum plates as raw materials, and produces products including roof panels, wall panels, interior decorative panels, and ceilings. The characteristics of the glazed tile roof profile forming machinery include:

1.Production process automation:

The equipment can automatically produce finished products of different lengths according to the data set by the computer, and the operation is simple.

2.High product quality:

The finished products produced have a smooth and even surface, without scratches, and are easy to install and construct.

3.Multifunctionality:

It can process substrates of various colors to meet diverse needs.

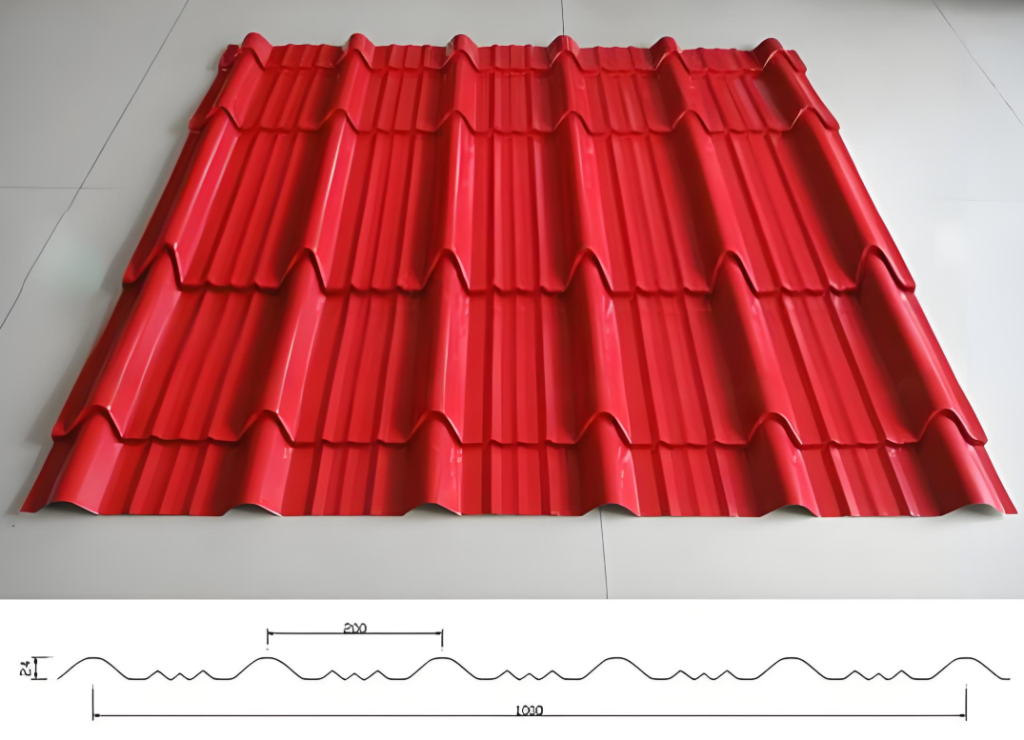

Profile drawing :

Application areas and advantages:

The glazed tiles and decorative materials produced by glazed tile roof profile forming machinery are widely used in various buildings, including urban flat to sloping, villa roofs, tourist scenic spots, etc. Its advantages include:

- Lightweight and high-strength:

The unit mass is only 1/10 of traditional ceramic tiles, but the strength is higher. - Easy installation:

Construction is not affected by seasons, reducing construction intensity and improving efficiency. - Beautiful and durable:

Rich in colors, preserving the traditional shape of ceramic tiles, reflecting classical and traditional beauty.