Z purlin sections cold roll forming making machine is an equipment used for producing Z-shaped steel . The machine can achieve fully automatic fixed length cutting and automatic punching, with high production efficiency. The Z-shaped purlins rolled by it have good bending and compression resistance, as well as good flatness. The product can be used as the main load-bearing structure of large and medium-sized industrial and civil buildings, such as factory buildings, warehouses, locomotive depots, aircraft hangars, exhibition halls, cinemas, sports venues, and market flower sheds for roof load-bearing and wall support.

Z Purlin plays an important role in the field of construction, mainly reflected in the following aspects:

- High bearing capacity and stability:

The “Z” section design of Z Purlin endows it with high bearing capacity and stability, which can effectively resist external loads. This design enables Z Purlin to perform well under load and is an indispensable part of buildings and industrial structures. - Lightweight and high-strength:

Z Purlin is usually made of carbon structural steel or low-alloy structural steel, processed through hot rolling or cold bending processes. It is lightweight, high-strength, easy to handle and install, and can effectively save construction time and labor costs. - Convenient construction:

The reasonable cross-sectional shape of Z Purlin enables it to more effectively exert material properties under stress, reducing material waste. In addition, the installation process of Z Purlin is simple and fast, and can be quickly assembled with other components through bolt connections, greatly improving construction efficiency. - Widely used:

Z Purlin is not only suitable for supporting and reinforcing building structures, but also widely used in fields such as bridges and mechanical manufacturing. Z Purlin is commonly used as a support structure for roofs and walls in steel structure buildings; In bridge construction, Z Purlin is used as a component to bear the load of the bridge deck; In mechanical manufacturing, Z Purlin is used to manufacture the skeleton structure of machines.

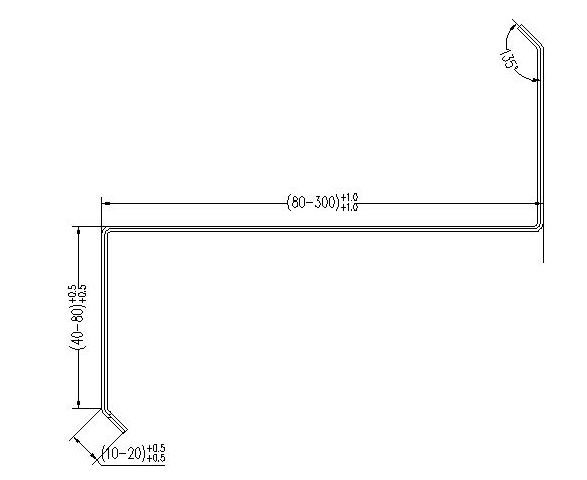

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

6.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

7.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Products Display:

Working video of the machine: