Below is a work flow video for you to watch:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.8-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20-30m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

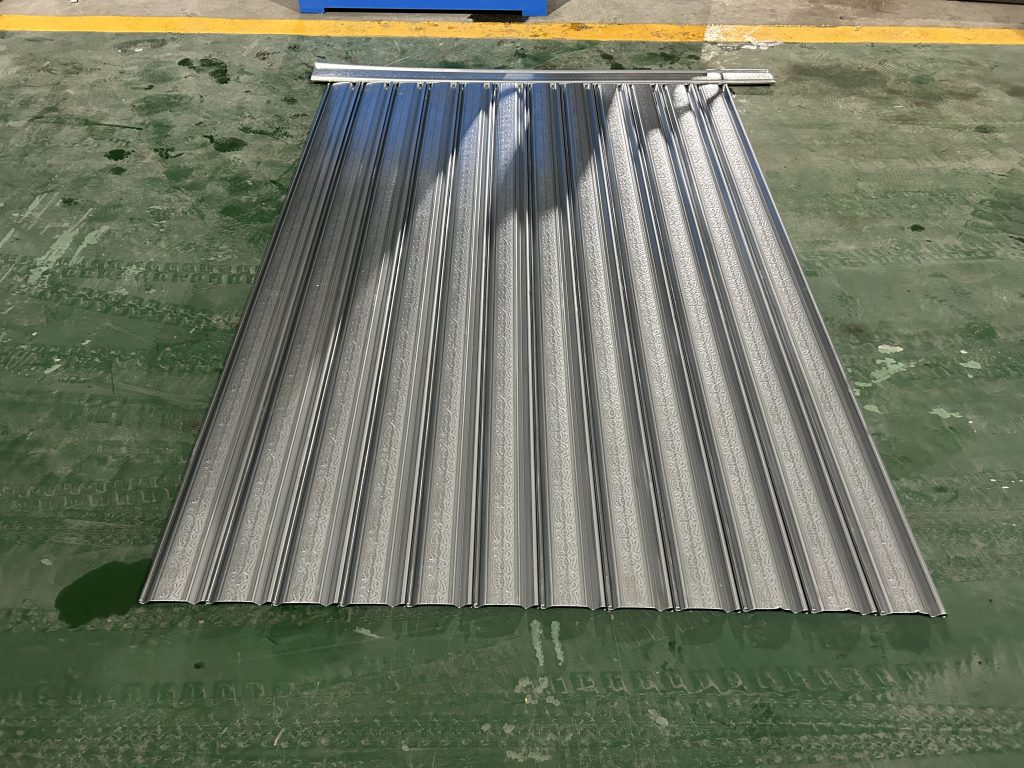

The advantage of high speed shutter door slats roll former:

- Quick opening and closing:

The opening and closing speed of high speed shutter door slats roll former is extremely fast, usually up to 0.5-1.5 meters per second for opening and 0.6-1.6 meters per second for closing. This fast opening and closing feature can quickly isolate different spaces, improve traffic efficiency, reduce waiting time, and is particularly suitable for scenarios where forklifts frequently enter and exit logistics warehouses. - High safety:

The high speed shutter door slats roll former is equipped with infrared safety sensing devices, light curtain protection devices, and other devices. When there is an object under the door, it can immediately stop descending or rise in the opposite direction to avoid trapping people and objects. In addition, the door body is made of high-strength materials, which can withstand frequent use and harsh environmental conditions. - Intelligent control:

Modern high speed shutter door slats roll former are usually equipped with PLC control systems, which can be linked with automation equipment in the workshop to achieve remote control, timed switching, or induction triggering functions. This intelligent design not only improves production efficiency, but also optimizes the environmental management of the constant temperature workshop. - Multifunctionality:

High speed shutter door slats roll former have multiple functions such as thermal insulation, cold insulation, insect prevention, wind prevention, dust prevention, sound insulation, fire prevention, and odor prevention. These functions make it widely applicable in various places such as food, chemistry, textiles, electronics, supermarkets, refrigeration, logistics, warehousing, etc.

Product Description:

The high speed shutter door slats roll former is a device used for making rolling shutter doors, mainly composed of a feeding machine, a feeding platform, a forming host, a forming shear device, a hydraulic station, and a computer control system, and is used in conjunction with a locking machine. This device is widely used in the production of rolling shutter doors in various industrial plants, warehouses, supermarkets, and shopping malls.