Dust Removal Board Roll Forming Machine

Metal dust removal boards are protective devices engineered to shield servers, industrial equipment, and other precision machinery from the intrusion of dust and particulate contaminants. Primarily constructed from metallic materials, they are characterized by high structural strength, long-term durability, and superior thermal dissipation performance, making them indispensable in maintaining operational integrity of critical equipment

Introduction of Dust Removal Board

Core Functions of dust removal boards

Metal dust removal boards are predominantly deployed between the air intake and exhaust ports of server enclosures. Their primary role is to prevent dust accumulation and clogging of heat dissipation vents, thereby ensuring unimpeded airflow for thermal management. Additionally, they serve as a physical barrier to protect internal components against external impacts or compressive forces.

Common Materials of Dust Removal Board

– Metallic materials: Steel and aluminum alloys are the most commonly utilized due to their exceptional strength, high hardness, and excellent heat dissipation properties, which are crucial for maintaining equipment performance in demanding environments.

– Cold-rolled steel sheets: Some products are fabricated from cold-rolled steel sheets with a thickness ranging from 0.5mm to 1.2mm. Processed through mechanical machining, these sheets exhibit superior anti-bending capacity and resistance to extreme temperatures, ensuring stability under varying operational conditions.

Structure and Performance

Manufactured using advanced techniques such as mechanical combined die punching and press forming, metal dust removal boards offer high customization in terms of thickness and color to accommodate specific industrial requirements. They boast an extended service life and enhanced corrosion resistance, ensuring reliability in harsh or humid environments.

In terms of functionality, these boards deliver comprehensive dust suppression efficacy that surpasses that of comparable products. Furthermore, certain models are integrated with windproof and dust-controlling features, further enhancing their protective capabilities in outdoor or high-airflow industrial settings.

The main parameters of the machine

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

0.3-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

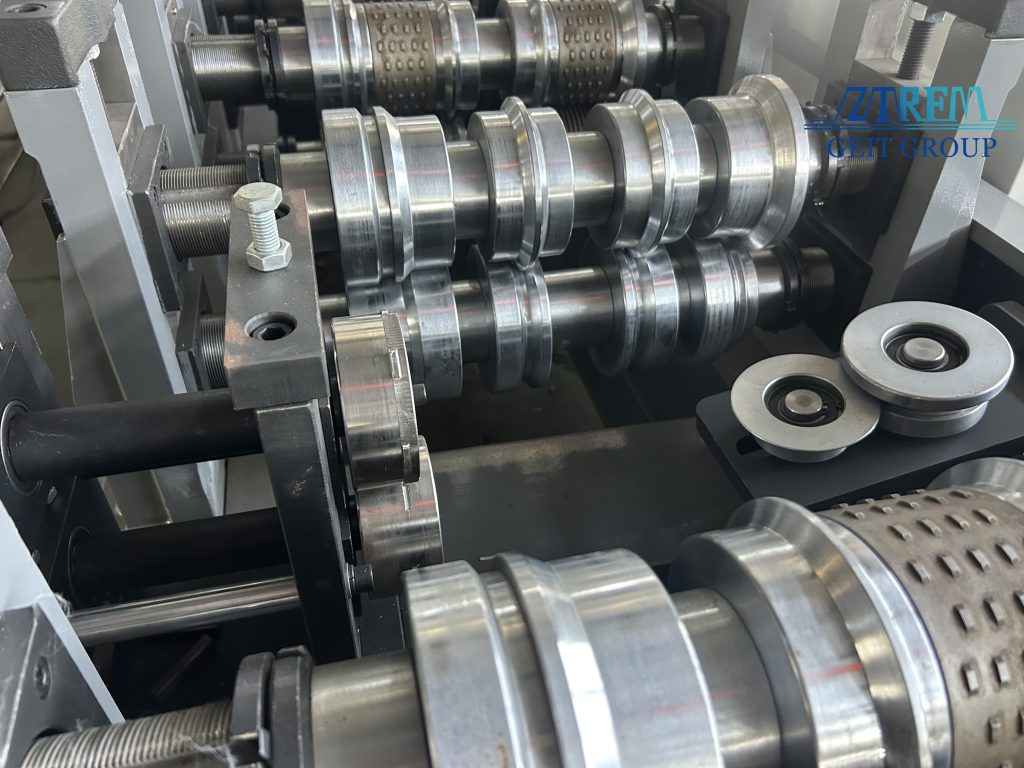

Roller station

|

16 rows(Due to your requirement profile)

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

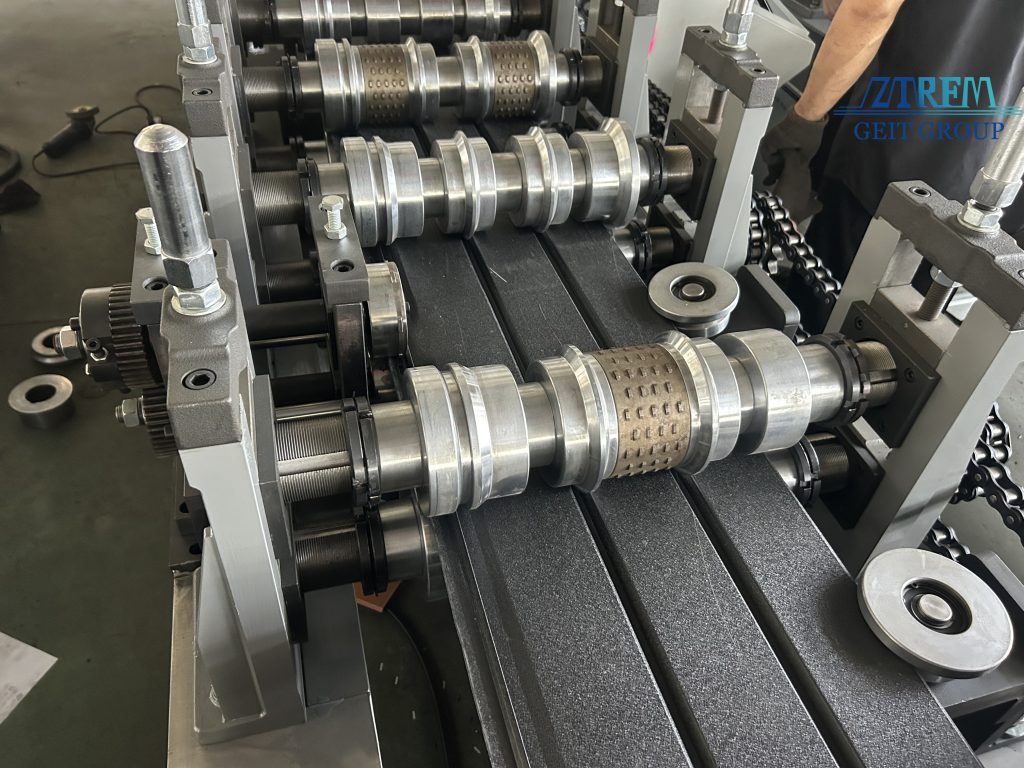

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

gear and Double Chain transmission/gearbox transmission optional

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

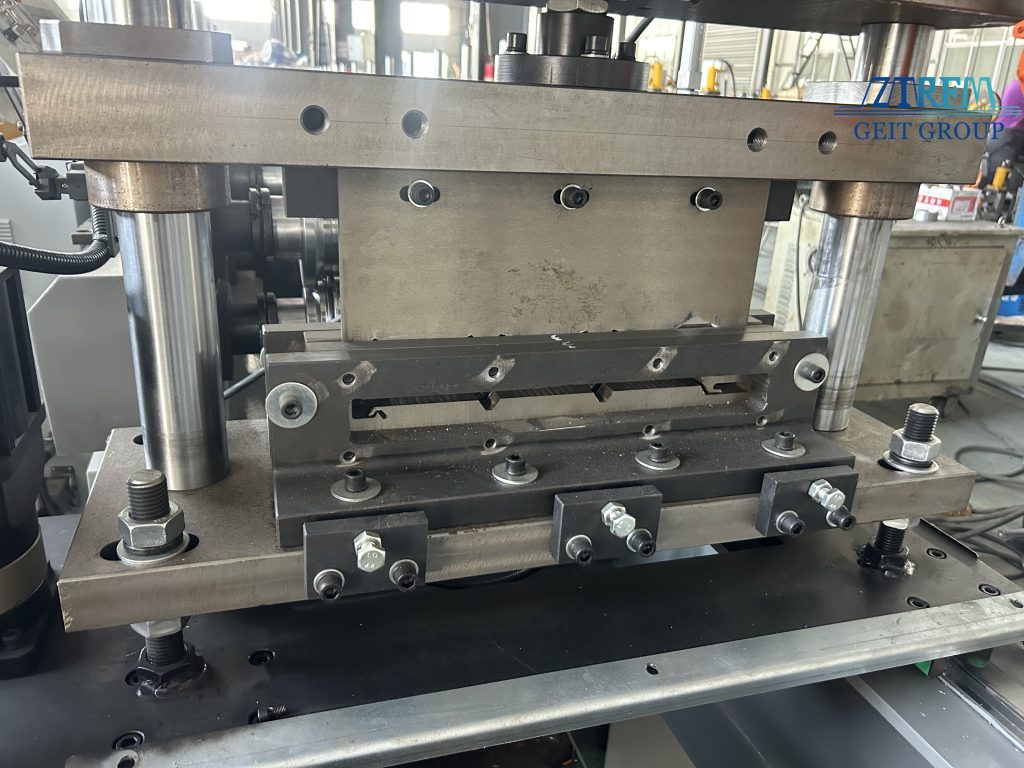

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW(normally)

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

25/min

|

Provide customized

|

||

Recommend related machine

OUR SERVICES

1. Installation & Training Support

We prioritize seamless onboarding to ensure your team can operate our equipment with confidence.

– Option A: For buyers visiting our factory for machine inspection, our technical experts will provide hands-on training sessions,

guiding your workers and technicians through on-site installation procedures, operational protocols, and maintenance fundamentals—tailored to your specific machine model.

– Option B: If an on-site visit isn’t feasible, we’ll deliver comprehensive digital support, including detailed user manuals, step-by-step installation videos, and operational guides.

These resources are designed to walk your team through setup and daily use clearly and efficiently.

– Option C: Should you require our technicians to travel to your facility, we’ll coordinate with your team to arrange on-location support.

Please note that accommodation, meals, and local transportation for our staff will need to be arranged by your side.

2. After-Sales Service Commitment

We stand behind the quality of our equipment with reliable post-purchase support:

– A full one-year warranty covers the entire machine, ensuring free repairs or replacements for any manufacturing defects or component failures within this period.

– Our technical support team is available 24/7 via email or phone to address urgent queries, troubleshoot issues, or provide real-time guidance.

– In the event of machine malfunctions, we guarantee prompt response and, where applicable, free repairs during the warranty period to minimize downtime and keep your operations running smoothly.