CZ Purlin machine

https://www.youtube.com/watch?v=EbVoYypJToQ

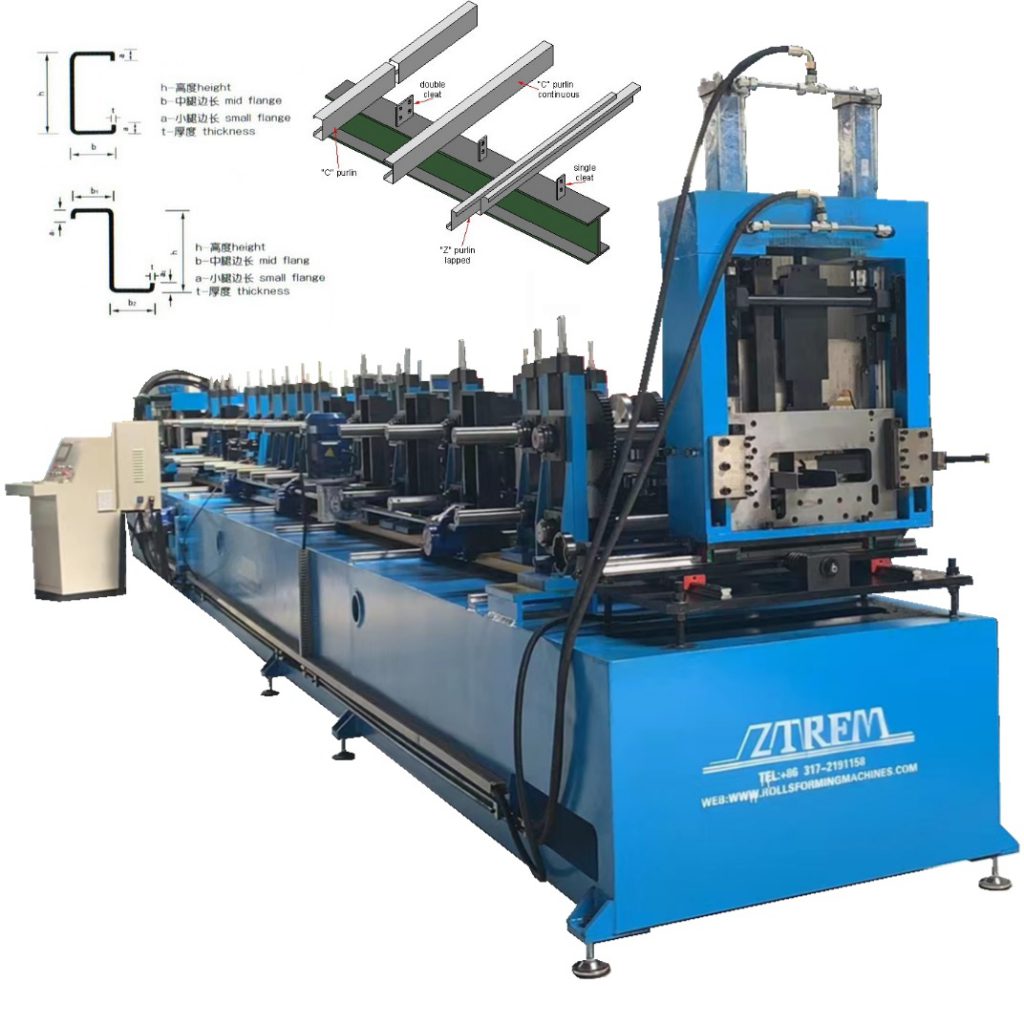

The CZ purlin machine is a cold-bending forming equipment that integrates the production functions of C-section steel and Z-section steel. It realizes rapid model change, stepless adjustment and efficient production through automation technology. The following is an integration of key information:

1.Core Functions and Features of CZ Purlin machine

Rapid Model Change and Stepless Adjustment

It supports rapid conversion from C-type to Z-type, completing model changes for any specifications (width 80-300mm, thickness 1.0-3.0mm) within three minutes, and the thickness adjustment accuracy can reach the millimeter level.

Adopting stepless technology, it can realize continuous production of standard/non-standard plate types without replacing cutters or rollers.

2.Automated Production Process of CZ Purlin

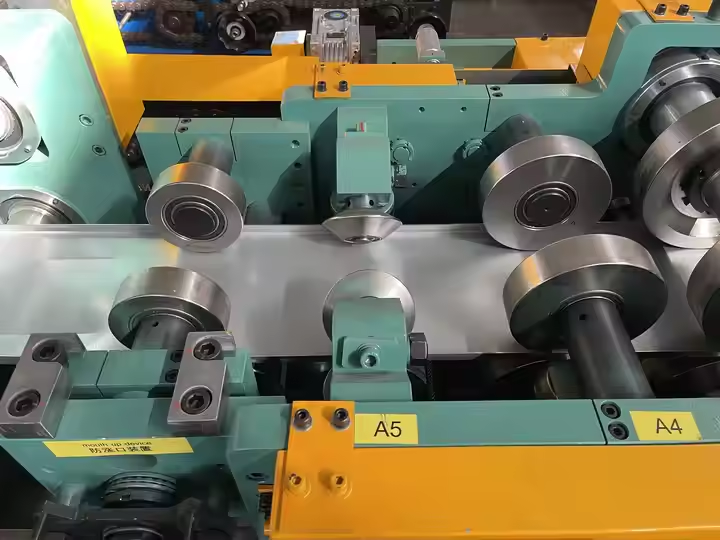

It integrates modules such as leveling, punching, shearing and straightening. The fully automatic control reduces manual intervention, with a plate output rate of 8-15m per minute.

Equipped with a Siemens PLC control system and servo motor drive, it ensures high-precision adjustment and stable operation.

3.Structural and Technical Advantages of CZ Purlin

The coaxial design reduces the risk of shaft breakage, and a multi-power system (such as hydraulic motor + servo motor) is adopted to ensure efficient operation.

Parameters such as web and flange can be adjusted to meet the needs of different building structures. It also features strong adaptability to raw materials, being compatible with various types of steel plates to ensure stable forming quality even for materials with certain hardness differences. In addition, the equipment is designed with a high degree of integration, saving floor space while simplifying the production line layout, which is conducive to reducing overall production site costs.

The intelligent monitoring system equipped can real-time track the production process, promptly alarm and feedback abnormal conditions, helping operators handle problems in a timely manner and improving the continuity and reliability of production.

Main parameters of CZ steel machine

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

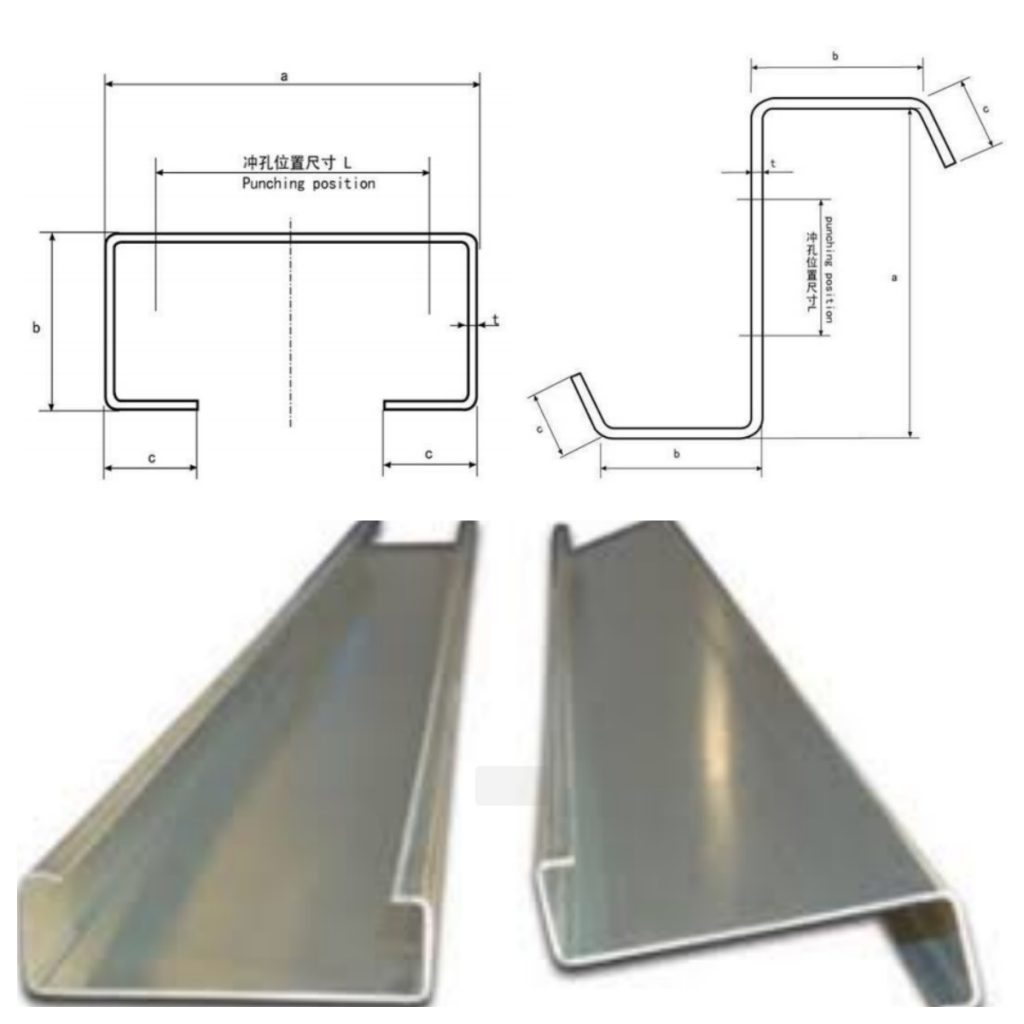

Finished product profile drawings

Recommend related machine