With the surge in demand for green buildings and high-quality housing, double-layer roofing tiles, with their dual advantages of heat insulation and noise reduction, as well as durability and wind resistance, have become the preferred building material for real estate, municipal engineering, and rural renovation. And a high-efficiency, Roofing Sheet Wall Panel Double Layer Roll Forming Machine is the key bridge to achieving profitability through high-quality products!

Applicable Scenarios: Covering the needs of the entire industry chain

• Large building materials factories:

mass-produce standardized double-layer roofing tiles, supplying real estate procurement and building materials wholesale markets

• Small and medium-sized enterprises:

flexibly undertake customized orders, focusing on regional markets (such as rural self-built houses and scenic area renovations)

• Engineering suppliers:

provide “just-in-time production – nearby delivery” services for municipal engineering and industrial park construction, reducing transportation costs.

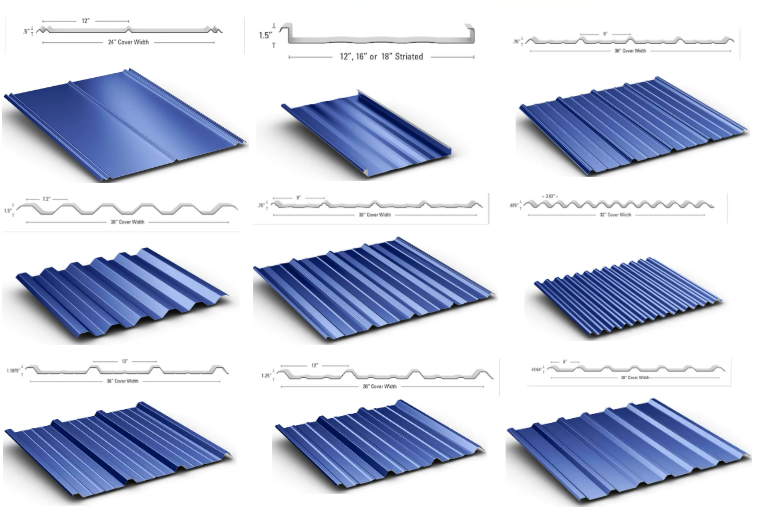

Pattern diagram:

Core Advantages: Solving Production Pain Points, Visible Cost Reduction and Efficiency Improvement

1.Ultra-High Capacity:

Dual-station synchronous pressing, producing 150-200 pieces per hour, with a daily capacity exceeding 3000 pieces, increasing efficiency by 40%+ compared to traditional equipment, easily handling large orders.

2.Flexible Production:

Compatible with cement, resin, and other materials, supports 10+ double-layer tile designs for customization, one-click production switching reduces mold replacement costs.

3.Intelligent Energy Saving:

Variable frequency motor + waste heat recovery reduces energy consumption by 25%, zero dust and noise, remote production monitoring and early warning via mobile APP, reducing labor costs.

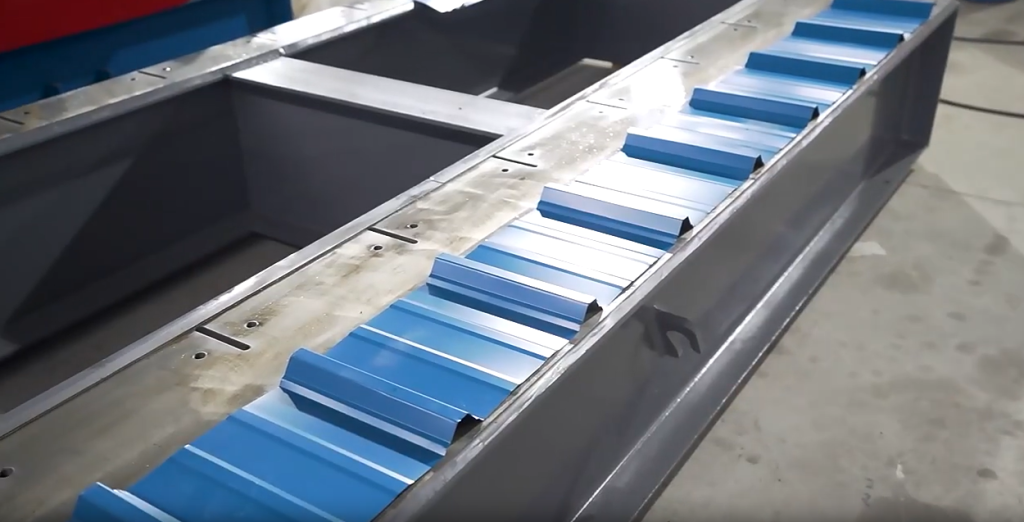

Finished product image:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.3-0.8mm Width:1250mm(As per profile drawing)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16+18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600(customize)

|

|||

|

Weight

|

11.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Service Guarantee: Comprehensive Support for Worry-Free Investment

• Pre-sales: Free factory planning and equipment selection solutions; customized production lines based on your production capacity needs and budget.

• During sales: Professional team provides on-site installation and commissioning; free operator training to ensure rapid equipment production.

• After-sales: Nationwide 24-hour response repair service; 3-year warranty on core components; lifetime technical upgrade support.