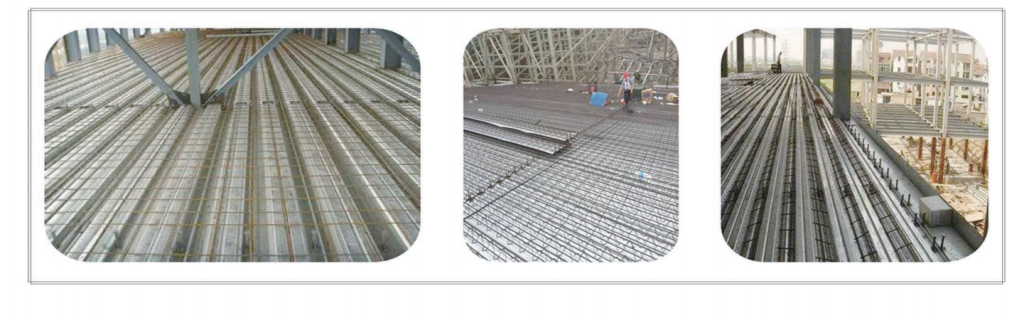

Application scenarios

The floor support plate produced by the Decking Manufacturing Equipment is a key component of steel structure buildings, so the equipment application is highly bound to the steel structure building scene, mainly including:

• Industrial plant:

used as floor load-bearing components for production plants and storage centers, suitable for the needs of large-span buildings;

• High rise buildings:

used as floor templates and load-bearing layers in high-rise residential and office buildings to reduce concrete usage and accelerate construction progress;

• Public facilities:

The floor structure of large public buildings such as sports venues, airport terminals, and convention centers must meet the requirements of high strength and large coverage area;

• Special buildings:

steel structure villas, temporary resettlement houses, etc., which require fast production and convenient installation.

Machine video:Decking Manufacturing Equipment

The Decking Manufacturing Equipment is a specialized forming equipment for producing floor support plates, widely used in steel structure factories, high-rise buildings and other scenarios. It is the core equipment for achieving industrial and standardized production, and can replace traditional manual processing to improve production efficiency and quality stability.

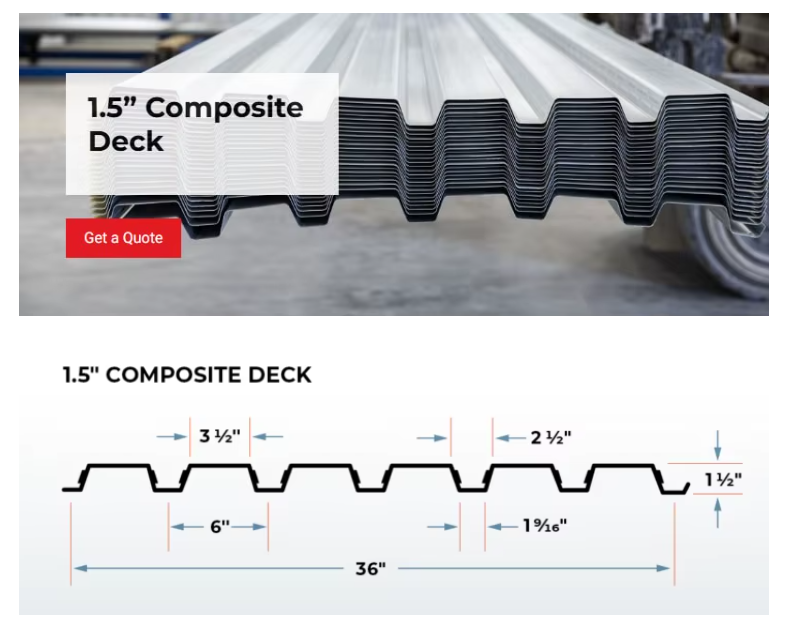

Decking Manufacturing Equipment For 1.5 B Deck Floor deck

Core Features

1. Efficient production

2. Stable accuracy

3. Flexible adaptation

4. Energy saving and low consumption

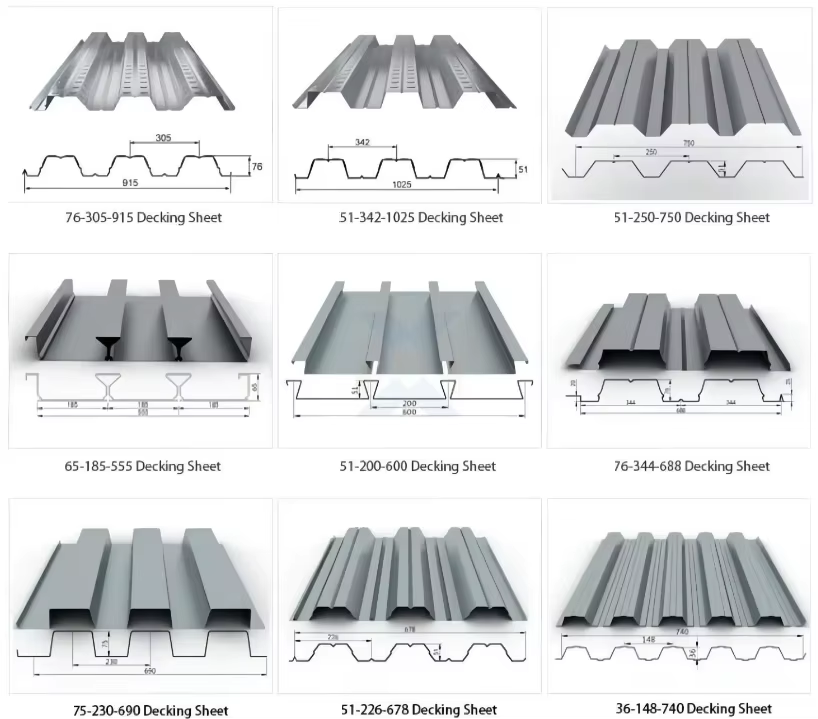

Pattern diagram

Product Attributes

|

1.Formed Material

|

GI

|

Thickness:0.7-1.2mm Width:1220mm (as request)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Capacity:12T With loading car

|

||

|

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

Diameter of shaft

|

95mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Double chain transmission

|

|||

|

Dimension(L*W*H)

|

About 14500*1700*1600(customize)

|

|||

|

Weight

|

About 13T

|

|||

|

4.Cutter

|

Hydraulic

|

Cutting blade material:Cr12 with quenched treatment

|

||

|

5.Power

|

Motor Power

|

15kw*2 sets

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

220V 50Hz 3Phase

|

As requirement

|

||

|

7.Control system

|

PLC and touch screen

|

Delta brand

|

||

|

Low pressure apparatus

|

Schneider

|

|||

|

Language

|

Chinese and English

|

|||

|

8.Forming Speed

|

8-15m/min

|

The speed is adjustable

|

||

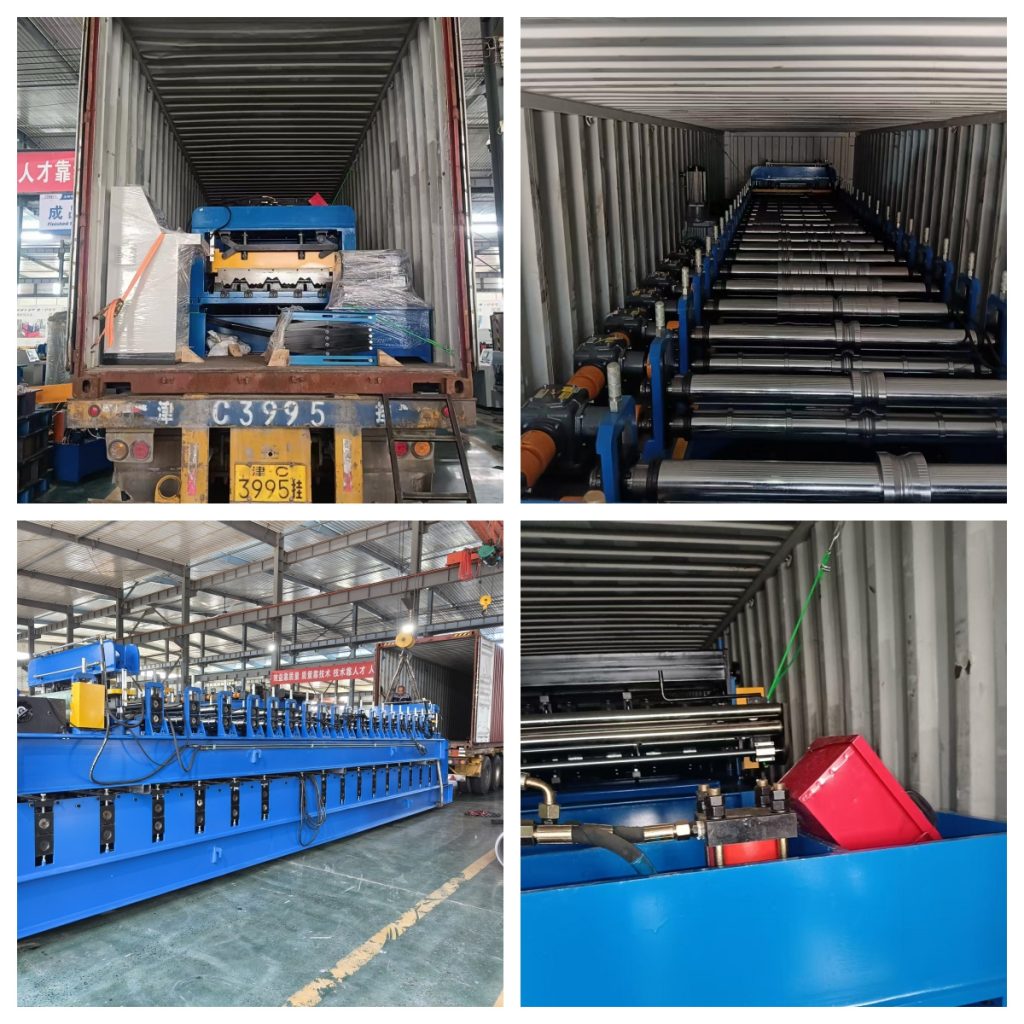

Packing & Shipping

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.