Solar Panel Bracket Roll Forming Machine

Amid the global shift towards a cleaner and lower-carbon energy structure, the photovoltaic (PV) industry has experienced explosive growth. As the “skeleton” of a PV system, the production efficiency and quality of PV mounting systems directly determine the stability and power generation benefits of PV power plants. Traditional PV mounting system production relies on manual operation, which suffers from drawbacks such as large precision errors, long production cycles, and high labor costs. Furthermore, it struggles to meet the diverse mounting system specifications required for different scenarios. Against this backdrop, Solar Panel Bracket Roll Forming Machine have emerged, breaking through production bottlenecks through technological innovation and becoming key equipment driving the upgrading of the PV manufacturing industry.

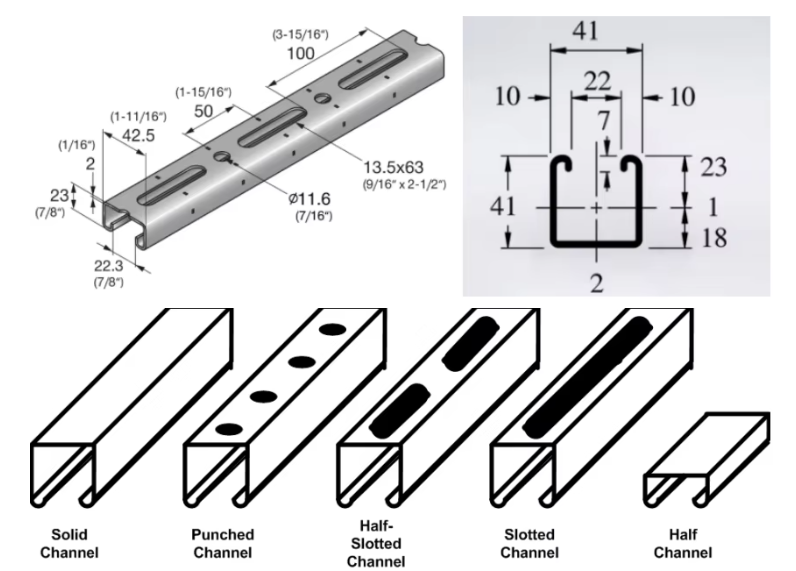

Pattern diagram:

Applicable scenarios:

Product Attributes :

| 1.Formed Material | GI | Thickness:0.8 to 1.8 mm (standard) | ||

| 2.Decoiler | 3 Tons decoiler | 3 Tons Manual decoiler(will give you as free) | ||

| 3.Main body | Roller station | 16 rows (As your requirement) | ||

| Diameter of shaft | 60 mm solid shaft | |||

| Material of rollers | Gcr15 | |||

| Machine body frame | 400 H steel | |||

| Drive | Gear and chains transmission | |||

| Dimension(L*W*H) | 15000*1800*1600(customize) | |||

| Weight | 5T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 7.5KW*2 sets,Siemens brand | ||

| Hydraulic system power | 15 KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

| 8.Forming Speed | 25 m/min | The speed depends on the shape of the tile and the thickness of the material. | ||

Full-Process Automation: Say Goodbye to “Manual Dependence,” Double the Efficiency

Traditional photovoltaic (PV) bracket production processes are complex, and manual operation is not only inefficient but also prone to product scrap. The new generation of PV bracket machines achieves full-process automation, from raw material loading and cutting to finished product unloading, requiring no manual intervention. After implementation, one company saw a 150% increase in daily production capacity per production line, a 60% reduction in labor costs, and a defect rate dropping from 3% to below 0.5%, significantly enhancing its market competitiveness.

High-Precision Intelligent Manufacturing: Millimeter-Level Error, Ensuring Power Station Safety

PV brackets need to withstand complex weather conditions, and precision affects module installation and power generation efficiency. Traditional manual production struggles to guarantee dimensional consistency, while PV bracket machines, with high-precision components and an intelligent control system, achieve servo motor positioning accuracy of ±0.1mm. Real-time detection systems automatically correct errors, ensuring product compliance with standards and guaranteeing long-term stable operation of the power station.

Flexible Adaptability: Meeting Diverse PV Scenarios

Different PV projects have varying requirements for bracket specifications, and traditional equipment changeovers are time-consuming. Modern photovoltaic (PV) mounting machine is highly adaptable, supports processing various materials, and can quickly switch molds and programs, reducing changeover time to within 30 minutes. It can efficiently handle the demand for “multi-variety, small-batch” orders.

Green and Energy-Saving: Aligning with the Environmental

Protection Mission of the PV Industry The PV mounting machine adheres to environmental protection principles, employing low-energy-consumption drive and waste heat recovery technology. Overall energy consumption is reduced by more than 20%, material utilization is increased to 98%, and steel waste is reduced. Simultaneously, noise control meets standards, creating a comfortable production environment and becoming an important link in the green chain of the PV industry.