Full Automatic Steel Frame C Z Purlin Roll Forming Machine are automated forming equipment specifically designed for processing CZ-shaped purlin. As a key piece of equipment in the steel structure manufacturing industry, they are widely used in factory construction, warehouse racking, photovoltaic brackets, container frames, and light steel villa keels. Their core function is to process raw materials such as coils or plates into C-shaped or Z-shaped steel products through a continuous cold-bending process, providing standardized, high-precision core components for various steel structure projects and promoting the efficient development of steel structure buildings and related industries.

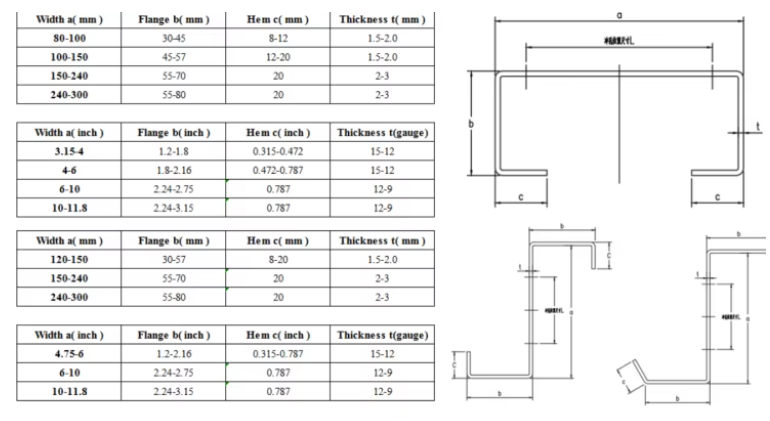

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Core Functions: Fully Automated Forming, High-Efficiency Output

The CZ section steel machine utilizes cold bending forming technology to achieve fully automated production. Through automatic uncoiling and leveling of raw materials after pre-treatment, continuous cold bending forming is followed by precision roll extrusion and shaping. Cutting to length and finished product conveying are then carried out precisely according to set parameters. Its production speed reaches 10-20 meters/minute, with an 8-hour capacity of 4800-9600 meters, increasing efficiency by 5-8 times compared to traditional processes and significantly reducing human error and safety risks.

Technical Advantages: High Precision and Stability, Ensuring Product Quality

Equipped with a servo drive and CNC system, the CZ section steel machine achieves forming accuracy of ±0.5mm and cutting accuracy of ±1mm. The high-strength machine body, combined with Cr12MoV die steel rolls, allows for continuous production of over 100,000 meters. A real-time monitoring system dynamically monitors production parameters, automatically stopping and alarming in case of abnormalities to ensure product quality meets standards.

Flexible Adaptability: Adjustable to Multiple Specifications, Meeting Diverse Needs

For different specifications such as C100-C300 and Z100-Z250, the CZ section steel machine supports rapid roll switching (completed in 1-2 hours) and intelligent parameter adjustment, eliminating the need for complex mechanical adjustments. It can meet both mass production and customized orders, aligning with modern steel structure production models.

Application Value: Cost Reduction and Efficiency Improvement, Driving Industrial Upgrading

The CZ section steel machine significantly reduces enterprise costs: labor is reduced by 60%, and material utilization exceeds 95%. It also improves production and installation efficiency, facilitating rapid order delivery. From an industry perspective, it promotes the transformation of steel structure production towards automation, aligning with the modernization trend of the construction industry.