Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,PPGL,AI,Etc.

|

Material Thickness:0.35-0.6mm

|

||

|

2.Decoiler

|

Hydraulic decoiler(optional)

|

give you as free

|

||

|

3.Main body

|

Roller station

|

Due to your requirement profile

|

||

|

Diameter of shaft

|

Due to your requirement profile

|

|||

|

Material of rollers

|

High Grade 45# Forged Steel, hard chrome plated on the surface(Chrome Thickness:0.05 mm)

|

|||

|

Machine body frame

|

Due to your requirement profile

|

|||

|

Drive

|

Double Chain transmission/gearbox transmission

|

|||

|

Dimension(L*W*H)

|

Due to design

|

|||

|

Weight

|

Due to design

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW(normally)

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

As your requirement

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-25m/min

|

Provide customized

|

||

Product Description:

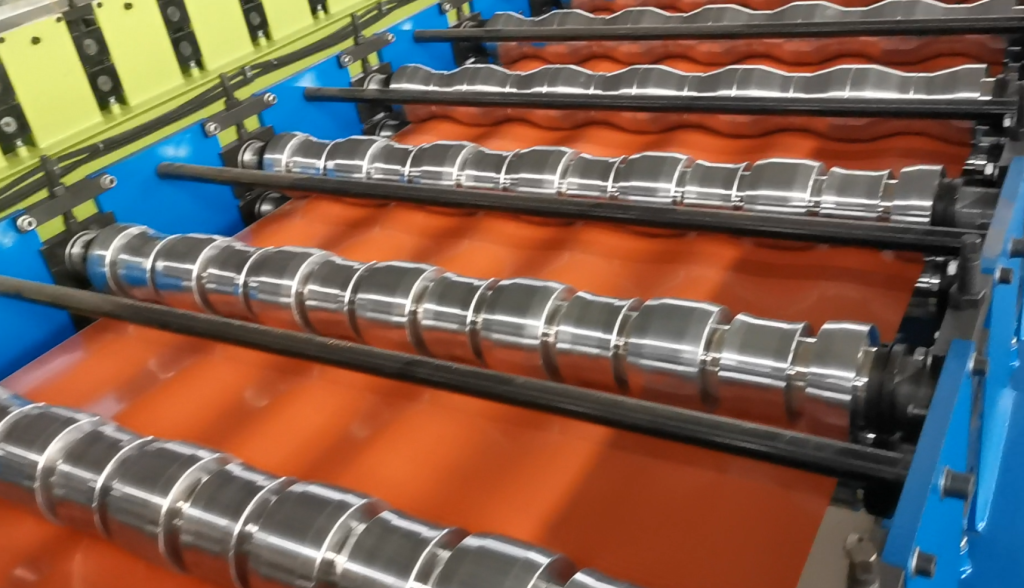

The high speed glazed tile roll forming machine is a device used for producing glazed tiles, mainly used for three steps: feeding, forming, and post forming cutting. The products produced have the characteristics of smooth and beautiful appearance, uniform paint patterns, high strength, and durability, and are widely used in the construction of industrial and civil buildings’ surfaces and walls. The market positioning of glazed tile machines is clear, suitable for the roof and wall construction needs of various construction projects. Its efficiency, accuracy, and safety have earned it high praise in the market. The high degree of automation reduces manual intervention, lowers labor intensity, and improves production efficiency.

Advantages of the machine:

1.Efficiency:

The high speed glazed tile roll forming machine can achieve continuous production, greatly improving production efficiency, meeting large-scale production needs, and helping enterprises stand out in fierce market competition.

2.Accuracy:

This machine adopts high-precision processing technology, which can ensure the accurate size and uniform texture of the tiles produced, providing high-quality building material choices.

3.Safety:

The machine is equipped with various safety protection devices, effectively reducing safety risks during operation and ensuring the safety of operators.

4.Reliability:

After strict quality control and testing, the high speed glazed tile roll forming machine demonstrates excellent reliability and stability, ensuring the continuity and stability of the production process.

5.High degree of automation:

The high degree of machine automation reduces manual intervention, lowers labor intensity, and improves production efficiency.

6.Save time and costs:

Through continuous production, the production cycle is greatly shortened, saving time costs, and the high-efficiency production mode also effectively reduces production costs.

Product features:

- Beautiful appearance:

The glazed tiles formed by the rolling and stamping die of this machine have the characteristics of beautiful appearance, antique elegance, and exquisite and unique shape. - Reliable quality:

The surface of the product is flat and smooth, without scratches, making it easy to construct and install. - Diversification:

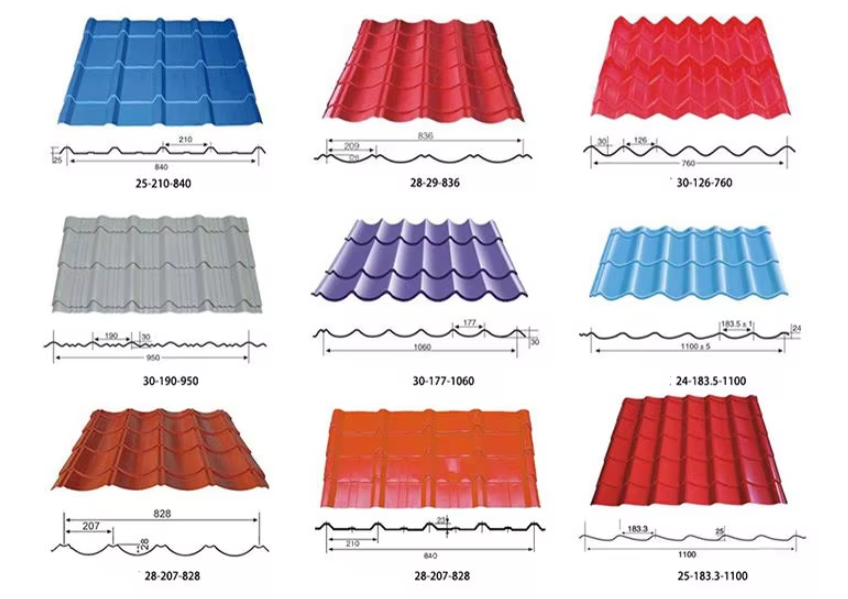

Glass tile machines can produce various shapes and sizes of glass tiles according to different molds.