Product Description:

High Quality Bending Cold Forming Angle bar Making Machine is a specialized forming equipment that processes metal coils (such as steel strips) into right angle or specific angle angle angle steel profiles through continuous rolling, extrusion and other processes. It is widely used in fields such as steel structures, mechanical manufacturing, power towers, and building brackets. It is a key equipment for achieving large-scale and standardized production of angle steel. Compared with traditional cutting and welding processes, it can greatly improve production efficiency and product quality stability.

Video Description:

Core technological advantages

1. High efficiency and high yield:

By adopting continuous rolling technology, 24-hour uninterrupted production can be achieved, and the daily output of a single production line can reach 5-15 tons (depending on the specifications of angle steel), far exceeding the efficiency of traditional manual processing.

2. Stable accuracy:

Through multiple sets of rolling mills for progressive forming and CNC cutting to length, the cross-sectional size error of angle steel can be controlled within ± 0.3mm, length error ± 1mm, and angle deviation ≤ 0.5 °, meeting the accuracy requirements of high-strength structural components.

3. Flexible adaptation:

Simply replace the corresponding specifications of the rolling mill set (replacement time is about 2-4 hours) to produce different types of angle steel (such as ∠ 25 × 25 × 3, ∠ 100 × 100 × 10, etc.), adapt to multi specification order requirements, and reduce equipment duplication costs.

4. Energy saving and environmental protection:

The processing process has no welding smoke and less cutting waste (with a material utilization rate of over 95%), and is controlled by a variable frequency motor, which reduces energy consumption by 15% -20% compared to traditional equipment, in line with the concept of green production.

Applicable scenarios and selection points

• Steel structure industry:

producing load-bearing angle steel for building frames and supporting columns, requiring equipment with high-strength rolling capacity and suitable for thick walled angle steel with a thickness of 6-20mm.

• In the field of power communication:

the manufacturing of tower angle steel for transmission towers and communication towers requires equipment to support long fixed length (such as 12 meters) processing and have punching function to meet the requirements of tower assembly.

• Light industry manufacturing:

producing thin-walled angle steel (thickness 2-5mm) for shelves, home appliance brackets, and medical devices, with a focus on rapid equipment changeover and small batch multi specification production capacity.

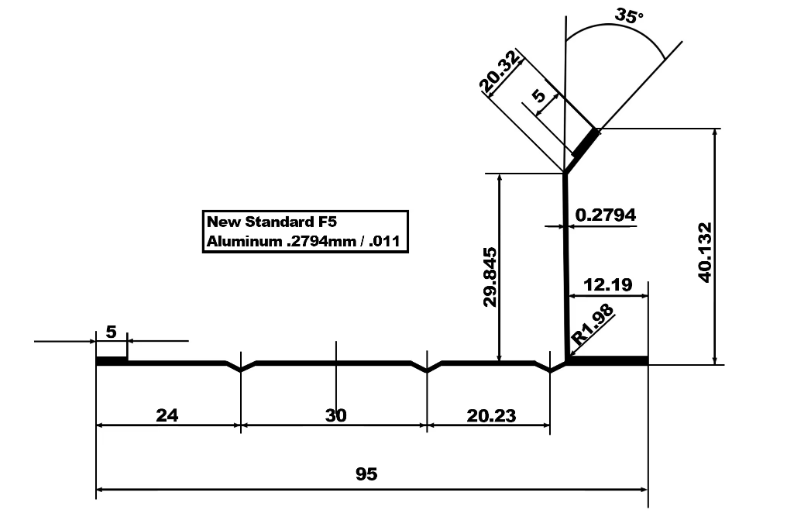

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

GI

|

Thickness:0.2-0..4mm (customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Key structural components

1. unwinding and leveling mechanism:

including unwinding machine (with tension control system to prevent steel strip deviation), leveling roller group (mostly cylindrical rollers arranged vertically, correcting steel strip by adjusting pressure), which is the basis for ensuring the accuracy of raw materials.

2. Rolling system:

The core consists of the rolling mill unit and transmission device. The rolling mill is made of high-strength alloy material (such as Cr12MoV), with a hardness of HRC58-62 after heat treatment, ensuring wear resistance and service life; The transmission device drives the rolling rolls to rotate synchronously through motors and reducers, ensuring stable rolling speed (conventional speed 10-30 meters/minute, adjustable as needed).

3. Fixed length cutting mechanism:

The mainstream adopts hydraulic cutting or flying saw cutting technology. Hydraulic cutting is suitable for small and medium-sized angle steel, with a cutting accuracy of ± 1mm; flying saw cutting is targeted at large angle steel, and can achieve “non-stop cutting” in the continuous conveying state of angle steel, avoiding the impact of downtime on efficiency.

4. Control system:

Modern angle steel forming machines are commonly equipped with PLC numerical control systems and touch screen operation interfaces. Operators can intuitively set parameters such as rolling speed, angle steel specifications, cutting length, etc. The system monitors the real-time operation status of the equipment (such as roll temperature, motor current), and automatically alarms in case of abnormalities, improving operational convenience and equipment safety.