The Full Automatic Double-Layer Roof Tile Machine is a specialized construction material production equipment designed for manufacturing double-layer roof tiles that combine thermal insulation, wind resistance, waterproofing, and decorative properties. It aims to meet the demand for high-quality roof materials in green buildings, premium residential housing, and industrial infrastructure, helping enterprises efficiently convert raw materials into market-recognized roof tile products.

Core Competitiveness:

1.High-Efficiency Production:

Equipped with a dual-station synchronous production system, it delivers a stable output of 150-200 tiles per hour, achieving over 60% higher efficiency compared to traditional single-machine setups. Supporting 24-hour continuous operation, it integrates automated feeding and cutting functions to minimize manual intervention, ensuring efficient order fulfillment.

2.Premium Output:

Utilizing high-precision CNC forming technology with a forming error ≤0.1mm, ensuring uniform tile profiles and tight interlocking. Compatible with various raw materials such as color steel plates, aluminum alloy plates, and weather-resistant wood boards, capable of producing categories like hollow insulated tiles and stone-textured decorative tiles. The tiles exhibit wind resistance up to Class 12 and strong weather durability.

3.Smart and Easy to Operate:

Equipped with a 7-inch touch screen, pre-installed parameter templates, and one-touch production start; features an intelligent fault warning system that provides real-time alerts with troubleshooting solutions, supports remote data monitoring, enabling even beginners to quickly get up to speed.

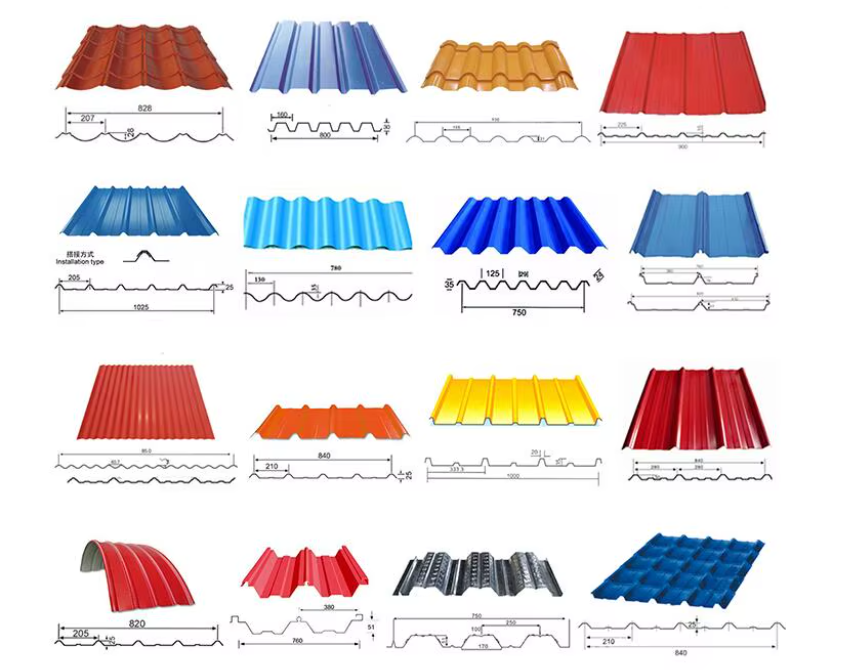

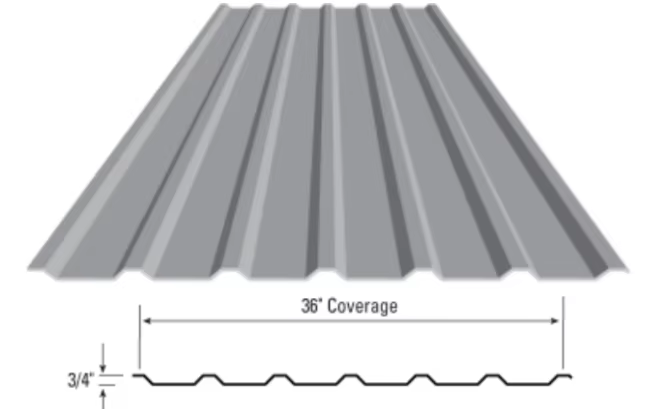

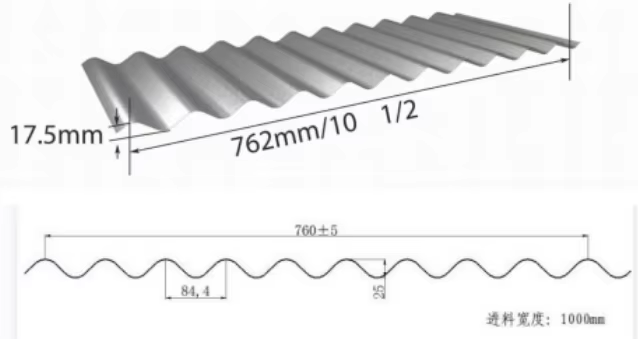

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI,GL

|

Thickness:0.3-0.8mm Width:1220mm(As per profile drawing)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16+18 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

As your requirement

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

8.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

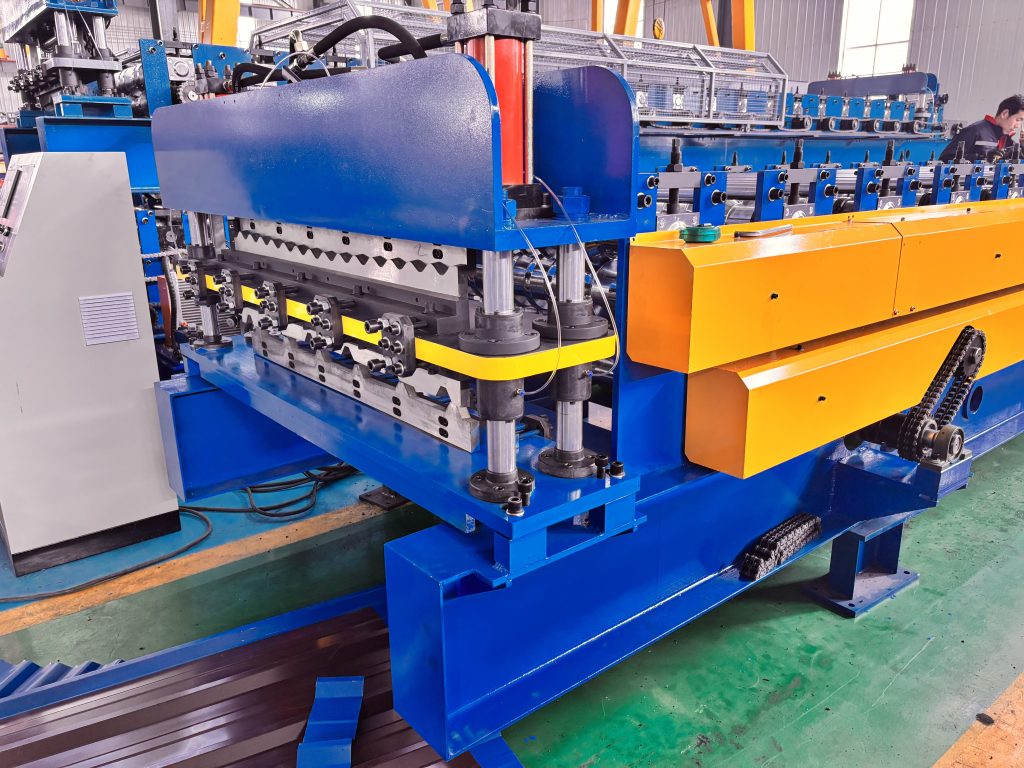

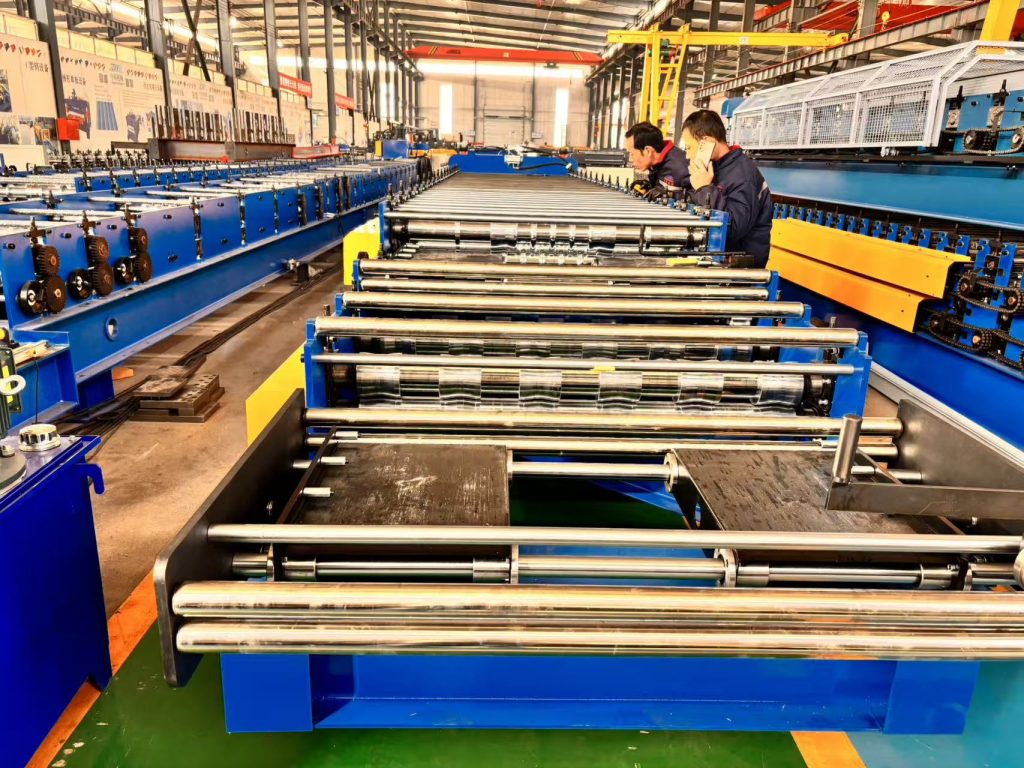

Machine image:

Packing method :

Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.