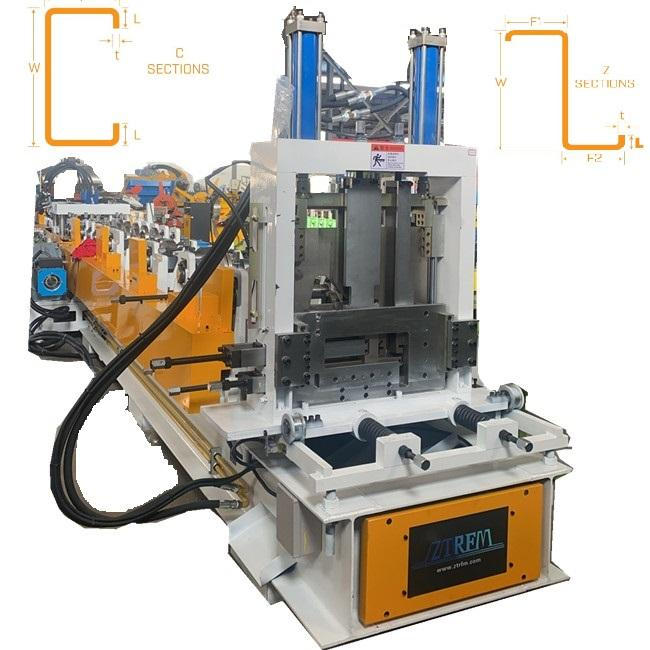

C Z Purlin Roll Forming Machine Steel Frame Purlin Machines

The C Z Purlin Roll Forming Machine Steel Frame Purlin Machines is an intelligent equipment designed specifically for the processing of C-shaped steel (groove shaped steel) and Z-shaped steel (zinc shaped steel). It can achieve full process automation production from metal coil raw materials to finished steel, and is widely used in steel structure construction, photovoltaic energy, warehousing logistics and other fields. Its core solution is the pain points of “strong manual dependence, low precision, slow shape change, and poor efficiency” in traditional section steel processing, and it is the core equipment of modern section steel processing.

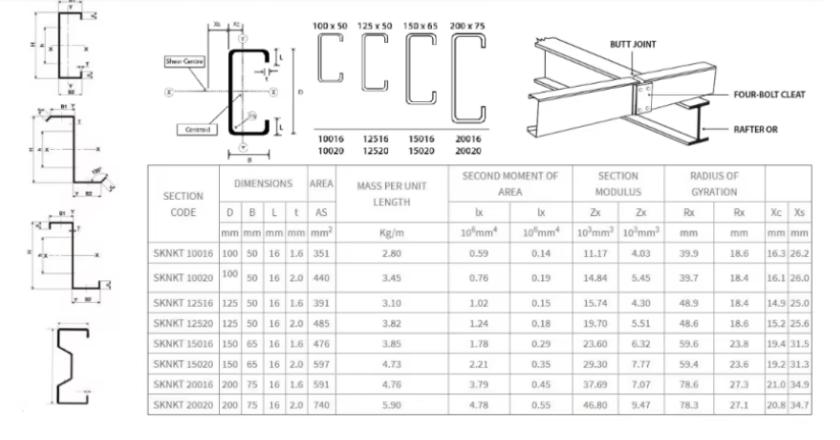

Pattern diagram

Key performance characteristics

1.High degree of full automation:

from raw material feeding to finished product stacking, there is no need for manual operation throughout the entire process. Only one person is needed to monitor a single device, which reduces labor costs by more than 60% compared to traditional manual auxiliary equipment (which requires 3-4 people);

2.Outstanding production efficiency:

With conventional equipment (suitable for 1.5-6mm thick plates), the daily (8-hour) production capacity can reach 8-15 tons, which is 50% -100% more efficient than traditional equipment (3-5 tons/day) and supports 24-hour continuous production;

3.Flexible specification adaptation:

One click switching of C/Z steel production mode, mold adjustment time only takes 15-20 minutes (traditional equipment takes 2-3 hours), can process metal plates with thickness of 1.0-6.0mm and width of 200-600mm, meeting the steel specification requirements of different scenarios;

4.Precision and quality stability:

Through servo control, multi-channel leveling, online detection and other technologies, the dimensional tolerance of finished steel is ≤± 0.5mm, with no scratches or deformations on the surface. The material utilization rate is increased to 97% (about 90% for traditional processes), reducing waste of corner materials;

5.Energy saving and safety:

By using variable frequency motors and hydraulic energy-saving systems, energy consumption is reduced by 20% -25% compared to traditional equipment; Equipped with emergency stop button, protective fence, overload protection and other safety devices, in compliance with industrial safety standards.

Applicable fields

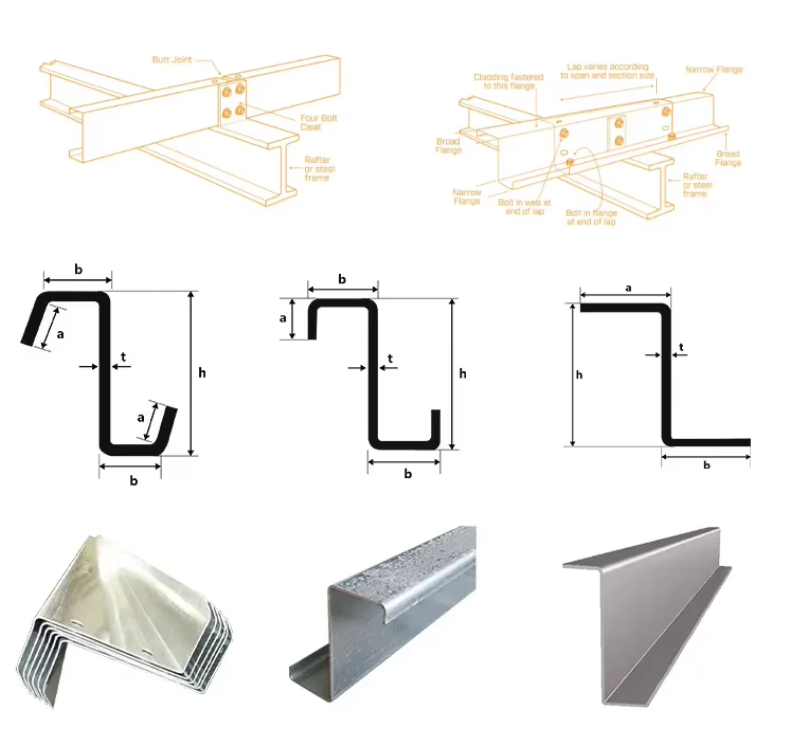

• Steel structure construction industry:

load-bearing purlins (C-shaped steel purlins) and supporting members (Z-shaped steel slant support) for production plants, warehouses, stadiums and other buildings to meet the needs of large-span buildings and improve structural stability;

• Photovoltaic energy industry:

Processing thin-walled CZ steel (thickness 1.0-2.5mm) for photovoltaic brackets, precise control of hole spacing, meeting the requirements of rapid on-site assembly of brackets, and ensuring the wind and pressure resistance performance of photovoltaic systems;

• Storage and logistics industry:

Customized storage shelves are made of special shaped CZ steel (with reinforcing ribs) to enhance the load-bearing capacity of shelf layers (single layer load-bearing can reach 500-1200kg), suitable for high-frequency storage needs such as e-commerce and cold chain;

• In other fields

such as automotive repair workstations, agricultural greenhouse frames, container accessories, etc., special specifications of CZ steel can be processed according to customized needs.

Product Attributes

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||