Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.3-0.8mm Width:1000mm/1250mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

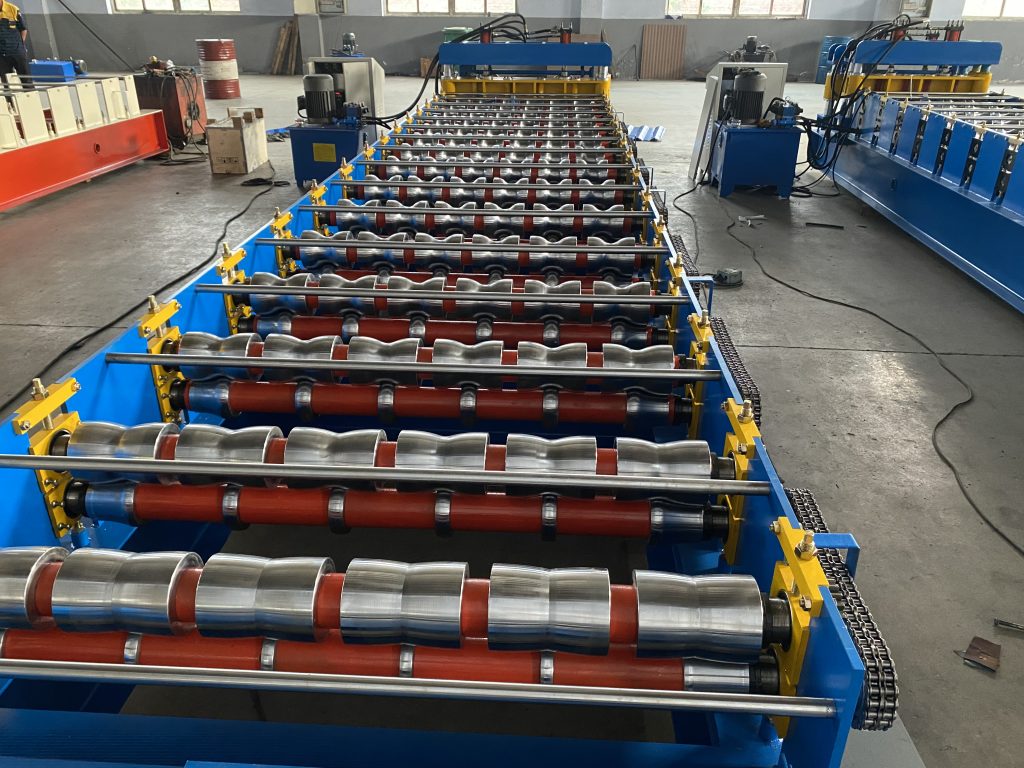

Roller station

|

16 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

8500*1600*1500 mm(customize)

|

|||

|

Weight

|

5.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

0-10m/min

|

The speed is adjustable

|

||

Product Description:

The glazed tile machine is a device used for producing glazed tiles, mainly used for building external roof panels, wall panels, and internal decorative panels or ceilings of houses. The main components of the glazed tile machine include the molding part, roller forming part, and cutting blade part.

The glazed tile machine mainly consists of the following parts:

1.Molding part:

The mold is driven up and down by a hydraulic cylinder to press the color steel into equidistant sections.

2.Roller forming part:

Dragged by a motor, the chain drives each roller to rotate, completing the formation of glazed tiles.

3.Cutting part:

The hydraulic cylinder drives the cutting tool to move up and down for fixed length cutting.

4.The production process of the glazed tile machine is as follows:

the colored steel plate enters the roller forming part for forming, and then is pressed into equidistant sections in the pressing part. Finally, the cutting blade part is cut to a fixed length.

Characteristics and application areas:

- Smooth and flat appearance:

The surface of the produced glazed tiles is flat, smooth, and scratch free, making it easy to construct and install. - Diversified design:

Multiple sets of different data can be set on the computer controller according to construction requirements, and the equipment automatically produces finished products of different lengths based on the set data. The glazed tile machine has no production length limit and can process substrates of various colors. - Multifunctionality:

Suitable for roof and wall decoration of various buildings, such as garden style factories, tourist attractions, villas, exhibition halls, etc. - Lightweight and High Strength:

The unit weight is only 1/10 of ceramic tiles, but the strength is high, suitable for urban flat to sloping, villa roofs, tourist scenic area buildings, etc. - Easy installation:

Easy to install, construction is not affected by seasons, reduces construction intensity, and improves construction efficiency.

Finished product image:

Products Display: