Full Automatic 16 Inch Aluminum Flush Roofing Soffit Panel Roll Forming Machine

During decoration, the construction of ceilings and suspended ceilings always gives people a headache: the accuracy of manual cutting is poor, and the joints are uneven in height; When the project schedule is tight, workers still cannot keep up with the progress by working overtime; It is difficult to adapt ceiling panels of different materials, and repeated debugging wastes materials… Don’t be troubled by these problems again! The new generation of ceiling panel machines has made a heavyweight debut, with three core advantages of “efficiency, precision, and peace of mind”, redefining ceiling construction standards and becoming a “construction tool” for decoration companies, engineering teams, and home decoration owners.

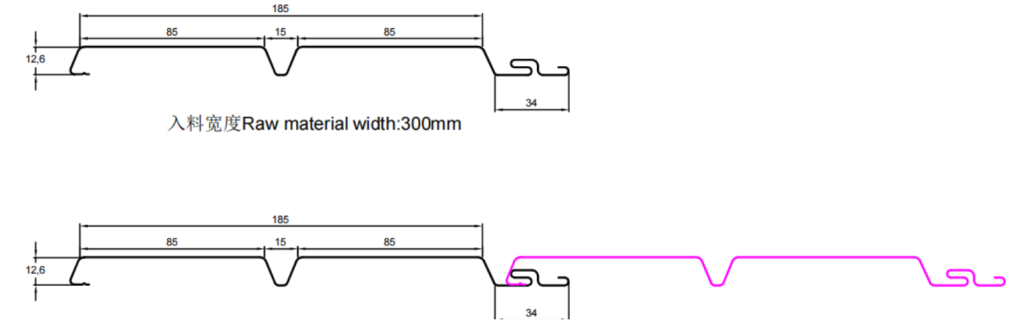

Pattern diagram:

Product Attributes :

|

Main frame

|

350mm H beam structure

|

|||

|

Material of rollers

|

High grade 45 high quality steel by CNC machining and hard chrome coating

|

|||

|

Forming stations

|

18 stations

|

|||

|

Diameter of shafts

|

Φ80mm solid(Guaranteed)

|

|||

|

Material of shafts

|

High grade 45#,with heat treatment

|

|||

|

Forming speed

|

About 0-30m/min

|

|||

|

Voltage

|

220V/50HZ/3P

|

|||

|

Transmission way

|

By gear box transmission

|

|||

|

Main motor

|

5.5kw

|

|||

|

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|||

|

Cutting type

|

Hydraulic cutting

|

|||

|

Driving method

|

By motor,5.5 kw

|

|||

|

Cover

|

Whole cover for roll former,without cutter.2 parts can slide side to side easily.

|

|||

Efficient construction: Three days in one day, no more rush in the construction period

Traditional ceiling construction, relying solely on manual cutting and assembly, often takes 3-5 days for a 100 square meter house ceiling. This ceiling panel machine is equipped with a high-speed drive system, which can accurately process 15-20 ceiling panels per minute. With the help of an automated feeding device, there is no need for manual repeated handling. The processing of a 100 square meter house’s ceiling panels only takes 4-6 hours, directly improving construction efficiency by more than 50%, making it easy to meet urgent and batch construction needs.

Precise and durable: Millimeter level precision, long-lasting appearance

The appearance and durability of the ceiling are all controlled by the precision of details. This ceiling panel machine adopts an imported laser positioning system, and the cutting error can be controlled within 0.5mm. Whether it is right angle splicing, curved shape, or reserved irregular hole positions, it can accurately match the design drawings, avoiding uneven gaps and skewed edges caused by manual operation. The installed ceiling is smooth and flat, and the visual effect is more advanced.

At the same time, the core components of the machine are made of high-strength alloy material. After 2000 hours of continuous operation testing, the failure rate is less than 0.5%. It is compatible with various common ceiling materials such as gypsum board, aluminum buckle board, bamboo and wood fiber board, and does not require frequent mold replacement. This reduces equipment loss and material waste, making long-term use more worry free.

Convenient and easy to operate: even beginners can get started, reducing labor costs

Worried about the complexity of machine operation and the need for professional technicians? This ceiling board machine completely breaks the “technical barrier”! Equipped with a 7-inch touch screen display and multiple commonly used ceiling processing modes (such as flat ceiling, secondary ceiling, double eyelid ceiling, etc.), simply enter the size parameters and start the processing process with one click. Novices can operate independently after 1-2 hours of training, without relying on high paying technical workers, helping decoration teams significantly reduce labor costs.

In addition, the machine is designed with a movable body, equipped with universal wheels and locking devices. Whether it is an indoor home decoration site or a large tooling construction site, it can be flexibly placed without fixed installation, saving space occupied by the site. Small space construction can also be easily handled.

Suitable for all scenarios: from home decoration to workwear, one-stop solution

Whether it is the living room, bedroom, kitchen and bathroom ceiling of home decoration, or the large-scale ceiling construction of industrial projects such as hotels, office buildings, shopping malls, etc., this ceiling board machine can be perfectly adapted.