Hat Shaped Ceiling Stud Omega Profile Making Machine Metal Furring Channel Roll Forming Machine

In the hat manufacturing industry, the crown as a core component that supports the hat shape and ensures wearing comfort, its machining precision and efficiency directly determine product competitiveness. Traditional manual cutting and semi-automated processing methods not only face the challenges of “high labor costs and insufficient production capacity,” but also often lead to hat deformation and soaring defect rates due to crown curvature deviations and uneven lengths, causing businesses to miss market opportunities. The emergence of the Metal Furring Channel Roll Forming Machine has brought a revolutionary breakthrough to the hat industry with its core advantages of “high efficiency, precision, and intelligence”!

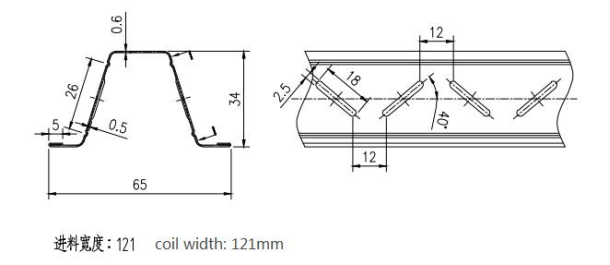

Pattern diagram:

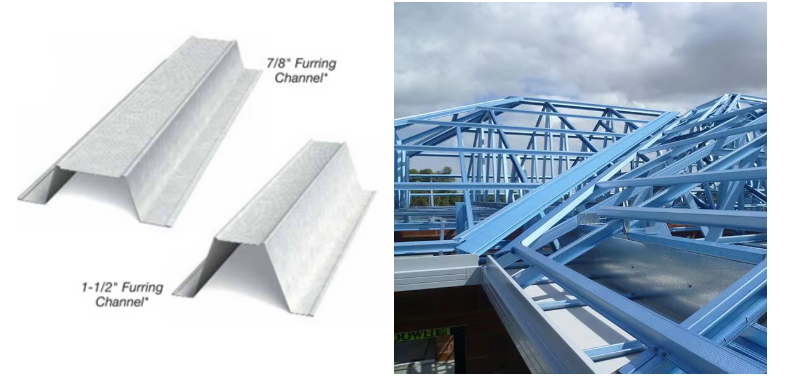

The Metal Furring Channel Roll Forming Machine is mainly used for producing building materials such as ceiling keels and partition keels. Its application scenarios include:

1. Ceiling system

Commonly used in the manufacturing of T-shaped ceiling keels, as a component of the main keel frame, it is used in conjunction with L-shaped connectors to achieve the fixation of the ceiling to the wall or column.

2. Partition wall system

In non load bearing partition walls, C-shaped keels serve as vertical frames, while U-shaped keels are used for perimeter fixation and are compatible with profiles produced by hat type keels machines.

3. Roof system

Some models of hat shaped keel machines can produce U-shaped load-bearing keels, suitable for roof structures that require additional load-bearing.

4. Light steel keel combination

Often used in conjunction with light steel keel machines to produce building materials such as color steel decorative ceilings and prefabricated houses.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

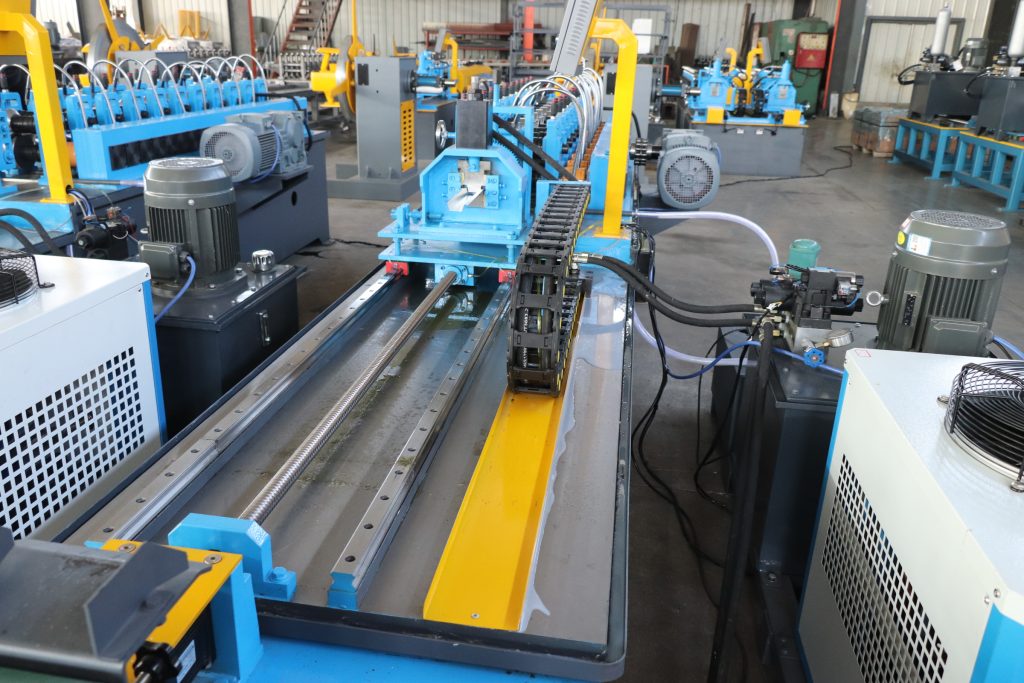

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Three Core Advantages: Addressing Production Pain Points for Hat Manufacturers

1. Fully automated operation, reducing costs and hassle

The equipment features an intelligent touch-screen interface, enabling one-click parameter setting and mold switching without the need for skilled technicians. New employees can be trained to operate independently in just 1 hour, with a single operator capable of managing 3-4 machines simultaneously, directly reducing labor input by 60%. Additionally, the built-in automatic feeding mechanism and waste recycling system minimize material waste, lowering overall production costs by 25%-30%.

2. Flexible production keeps pace with market trends

In response to the current production trend in the hat industry of “small batches and multiple styles,” the hat skeleton machine supports rapid mold change (mold change time ≤ 5 minutes) and offers customized mold services (7-day rapid mold opening). Whether it’s the thickened skeleton for winter/autumn thermal hats, the lightweight skeleton for summer baseball caps, or the specially curved skeleton for trendy novelty hats, it can be precisely adapted to help enterprises easily respond to market trends and quickly launch new products.

3. Durable and stable, ensuring uninterrupted production

The machine body is welded from 6mm thick cold-rolled steel plate, ensuring impact resistance and deformation-free performance. Core components (such as cutting knives and transmission gears) are made of high-strength alloy material, with wear resistance increased by 5 times, enabling uninterrupted operation for 8,000 hours without failure. Additionally, the equipment is equipped with an intelligent fault alarm system that continuously monitors critical parameters like voltage, temperature, and feeding speed. Upon detecting abnormalities, it immediately triggers pop-up alerts, significantly reducing downtime for maintenance.