Metal Shelf Rack Panel Roll Forming Machine: Ideal for Supermarket Storage Rack Upright

https://www.youtube.com/watch?v=3p1qTNXLnrs

Introduction of Supermarket Storage Rack Upright

Easy Operation with Zero Threshold for Quick Mastery

Supermarket Storage Rack Upright roll forming machines are centered on an intelligent control system, which transforms complex production processes into simple parameter-setting operations. Operators only need to input basic parameters such as the required shelf specifications and dimensions on the device’s touchscreen control panel, and the system will automatically drive the machine to complete the entire process from raw material processing to finished product output.

This intuitive and easy-to-understand interface eliminates the high technical and experiential requirements that traditional equipment imposes on operators. Even workers without long-term professional training can become proficient in a short time, significantly shortening the personnel training cycle.

The simplification of operations not only speeds up the production rhythm but also reduces the tedious steps of manual intervention.

For example, there is no need to repeatedly adjust the equipment or check dimensions manually; workers only need to monitor the operation status beside the machine. This not only reduces labor intensity but also minimizes safety hazards caused by human operational errors, making the production process more stable and secure.

– High-Efficiency Production, Achieving a Qualitative Leap in Output

Supermarket Storage Rack Upright roll forming machines adopt an integrated design, integrating multiple processes that traditionally require separate equipment—such as feeding, punching, shearing, bending, and forming—into a single machine for simultaneous execution.

Through the precise coordination of automated chains, raw materials go from entering the machine to becoming complete shelf products without manual transfer, realizing an efficient production mode of “one-time feeding, full automation.”

This high efficiency is particularly evident in production capacity: in traditional manual production or decentralized equipment processing, limited by manual speed and process connection efficiency, a skilled worker can produce at most dozens of shelves a day.

In contrast, relying on continuous automated operations, Supermarket Storage Rack Upright roll forming machines can easily achieve a daily output of hundreds of shelves. Even some high-speed models can exceed 1,000 units depending on the equipment type.

This means that in the same production time, the output of the forming machine is several to more than ten times that of traditional methods, significantly shortening the order delivery cycle, especially suitable for large-scale, batch production of shelves.

– Excellent Precision, Ensuring Stable Quality

Relying on advanced numerical control technology, the core components of Supermarket Storage Rack Upright roll forming machines (such as servo motors and precision guide rails) have extremely high operational accuracy, controlling production errors within millimeters or even smaller ranges.

The built-in real-time measurement and detection system continuously monitors key indicators such as shelf dimensions, angles, and forming radii during production. Once minor deviations are detected, the system will immediately adjust parameters automatically to ensure each produced shelf meets preset standards.

In contrast, in traditional manual production or semi-automated equipment processing, shelf quality often depends on workers’ experience—for example, whether the bending angle is standard or the punching position is accurate may fluctuate due to differences in workers’ status and skills, resulting in inconsistent sizes of products in the same batch and difficulties in assembly.

The roll forming machine completely eliminates this “human-dominated” instability, ensuring that each shelf has highly consistent dimensions and shapes, which not only improves product qualification rates but also provides reliable guarantees for subsequent shelf assembly and use.

– Cost Savings, Enhancing Enterprise Competitiveness

The cost advantages of Supermarket Storage Rack Upright roll forming machines are reflected in multiple dimensions: first, the reduction of labor costs. Automated production reduces reliance on skilled workers; usually, only 1-2 people are needed to monitor one machine, saving a lot of labor input compared to the traditional mode of “one person per machine” or even “multi-person collaboration.” Second, the compression of time costs.

High-efficiency production allows enterprises to complete more orders in the same time, accelerating capital turnover.

Finally, the saving of raw materials. The machine can minimize waste in raw material cutting and forming through precise parameter control—for example, avoiding material scrapping due to dimensional errors, ensuring every piece of raw material is used efficiently.

The comprehensive reduction in costs not only directly increases the profit margin of enterprises but also gives them greater pricing flexibility in market competition. Whether seizing market share through cost-performance advantages or investing saved costs in product research and development, it can bring long-term competitiveness to enterprises.

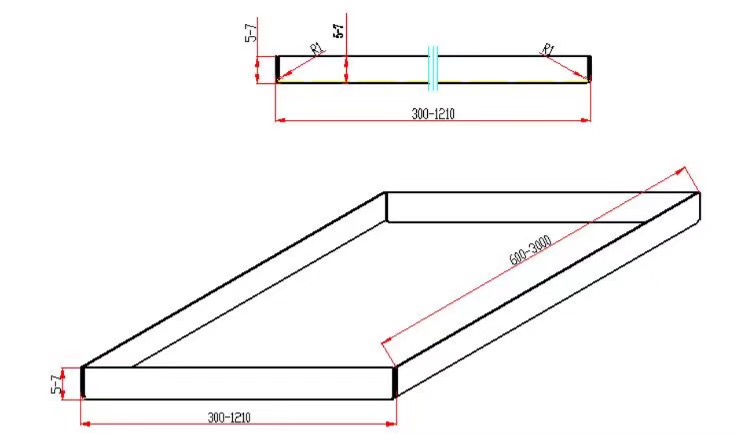

Profile drawings

The main parameters of Supermarket Storage Rack Upright Machine

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:2-2.5mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

16 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

Cr12 with quenched treatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

7500*1200*1400(customize)

|

|||

|

Weight

|

About 8T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

2*11KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Recommend related machine